In the fiercely competitive global marketplace, manufacturers confront many challenges. One of those dilemmas is that product life cycles are too short to warrant investment in traditional, custom-built "hard" automation. The equipment will not be used long enough to provide a positive return on investment (ROI). A second dilemma is that production lines must be fully operational within a short time to coincide with a narrow window of opportunity for product sales. Design time for traditional production lines is too long. The life cycle of many consumer products, such as cell phones, is less than 1 year. A third dilemma is how to reduce inventory by producing smaller lot sizes.

Manufacturers and automation engineers address these issues every day. They ask, "How do I justify the capital investment in equipment and meet the delivery time for the first product run?" And, "How do I justify the costs associated with future products and those not yet conceived?"

Many companies have answered these questions by giving up on automation altogether and relying on mostly manual, "lean manufacturing" operations. This strategy incurs a relatively low capital investment, but typically a much higher operating investment over time, because it requires more operators. In addition, lean manufacturing limits product quality, part tracking, high-speed operations and repetitive operations, because of the risk of repetitive strain injuries.

The Flexible Alternative

One solution to these limitations is an automated assembly system based on processes rather than the end products. Most products can be broken down according to the processes used to assemble them, such as screwdriving, dispensing, welding or pressing. These processes are typically repeated from one product to the next.In a traditional, fixed automation system, these processes are rigidly timed and located to assemble a specific product. In a process-based automation system, each process is performed by a flexible, standardized module. These modules can be fully automatic or semiautomatic. Because the modules are similar in size and because they share a common control system, they can be arranged quickly and easily in any order, at any time. Additionally, each module is self-contained, so it can operate off-line, if necessary.

At the base level, the modules share a common mounting grid, docking ports and utilities. Quick-change tooling and "setup blocks" further assist changeover.

For the process-based strategy to work, the product must be designed around the processes that have been automated. Ideally, manufacturers should reuse these core processes as often as possible.

This will be a culture change for many manufacturers. Traditionally, manufacturers have wrestled with part design more than process design. You could argue that designing the process before the part is putting the cart before the horse. However, manufacturing is no longer in the horse and buggy era. Rather, because time to market is so critical to profitability, manufacturing is much more important than it was decades ago. The luxury of taking months or years to bring a product to market is no more.

For years, automation suppliers have preached about the merits of design for manufacturability and using the simplest pro-cesses possible to assemble a product. That subject is not new. What is new is the technology available for realizing these ideals.

In particular, advances in robotics have made standardized process modules a reality. For example, a standard robotic process module might consist of a machine base, a four-axis SCARA robot, a conveyor, guarding devices, pneumatic service, a controller and a human-machine interface. For high-precision applications, the module might also include machine vision or positioning stages.

Robotics play a key role in achieving flexibility. Robots can be programmed to perform various operations. Hard automation cannot be reprogrammed. And unlike hard automation, robots can handle different part sizes and shapes.

Process-based assembly systems have also benefited from improvements in control software. In a process-based system, the software oversees the entire line and determines what processes are needed when. Because hardware, software and electrical interfaces are standardized, manufacturers can configure the line so parts are directed to the correct processes without totally redesigning the system from scratch. Module A has the same cables that connect to the main line as Module B. Module A is physically the same size as Module B. This approach saves manufacturers tremendous time and money.

Standardized process modules provide other benefits, besides increasing flexibility. For one, process modules make the most of available floor space. This is an especially great benefit in clean room applications, where floor space is at a premium. Standardization also means that the operator interfaces, mechanical designs, electrical designs and software have a common touch and feel. This reduces training and operation expenses.

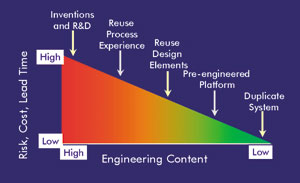

The key to ROI is eliminating custom production lines. The more logical route is to implement an automated assembly system that can build a product for 6 months, and then be easily reconfigured to build the next product. The ability to reuse the original capital investment over several years provides a much better ROI.

For more information about assembly systems, call 800-225-7378 or visit www.baysideautomation.com.

Process modules are linked by belt- or edge-style pallet conveyors. Like the cells they connect, the conveyors are comparably sized, with prewired umbilicals, on-board controllers and standardized connections.

Sidebar: The Benefits of Flexible Assembly Systems

- Longer economic payback period.

- Introduce new products faster.

- The ability to scale production capacity up or down to make the best use of capital equipment.

- The ability to produce small lot sizes in an order-driven manufacturing environment.

- Increased production efficiencies.

- Reduced production errors.

- Less production downtime.

- Less operator training.

- Use of common parts gives the system a common look and feel.