Traditionally, the Paris Auto Show features sleek bodies and stylish designs. But, during the two-week show last October, all the oohs and aahs were reserved for what’s under the skin. Automakers unveiled a wide variety of green cars featuring alternative propulsion systems. Suppliers also unveiled new technology, such as in-wheel electric motors, aimed at improving fuel efficiency and reducing emissions.

The underlying message from the Paris event was that the green car revolution, which started quietly a few years ago, was finally about to go mainstream. However, some of that green buzz died down by the time that the North American International Auto Show opened in Detroit last month.

Recent economic turmoil, coupled with low oil prices, have forced automakers and suppliers to rethink their green strategy. “All of a sudden, green cars aren’t in fashion with consumers,” says Dave Cole, chairman of the Center for Automotive Research (Ann Arbor, MI). “Economics is the big concern in the auto industry today. Somehow, we need to bridge the gap between where we are right now and the time when green cars are produced in high volumes.

“In recent months, there’s been a huge decline in hybrid sales,” adds Cole. “Things looked terrific six months ago, but not now. The threshold is $70-a-barrel oil. Anything lower than that makes green cars much harder to sell.”

Cole believes widespread interest in green car technology will heat up again in 2010. That’s when General Motors Corp. (GM, Detroit) plans to begin mass-producing the Chevy Volt at its Detroit-Hamtramck plant.

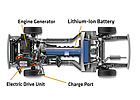

The much-anticipated car is touted as an extended-range electric vehicle. For trips up to 40 miles, the Volt will be powered by a 16-kilowatt-hour, T-shaped lithium-ion battery. Drivers will plug the front-wheel-drive, four-passenger car into a standard 230-volt household outlet for charging.

“We see the development of vehicles powered by electricity as key to the transformation of our industry,” says Bob Lutz, GM’s vice chairman of global product development. “And, advanced battery technology is at the heart of this transformation.”

To supply the Volt, General Motors plans to build the first lithium-ion battery pack assembly facility in the U.S. operated by a major automaker. The plant, which will be located in Michigan, will ramp up production in 2010 using cells supplied by LG Chem Ltd. (Seoul, South Korea) and its local subsidiary, Compact Power Inc. (Troy, MI).

At the recent Detroit show, several other automakers generated publicity by unveiling green cars:

- Chrysler LLC (Auburn Hills, MI) announced that it is developing a broad portfolio of electric vehicles, with the first models ready to go by next year. Chrysler’s completely electric ENVI powertrain will power five distinct platforms of vehicles, including a sedan, a sportscar, an SUV and a minivan.

- Fisker Automotive Inc. (Irvine, CA) unveiled the Karma, its first production car. The start-up company plans to use parts supplied by GM, such as the 4-cylinder gasoline engine that will be used when a driver exceeds the 50-mile electric-only range. The Karma will be assembled by Valmet Automotive Inc. (Uusikaupunki, Finland), a contract manufacturer than has built more than 1 million vehicles for customers such as Porsche and Saab.

- Ford Motor Co. (Dearborn, MI) outlined an ambitious green vision. It is partnering with Magna International Inc. (Aurora, ON) to develop a new line of battery-powered vehicles that will be ready by 2012. Magna will provide key components, such as electric motors, transmissions, motor controllers, energy storage systems and battery chargers.

- Honda Motor Co. (Tokyo) unveiled a five-passenger version of its Insight hybrid.

- Toyota Motor Corp. (Nagoya, Japan) displayed the third generation of its popular Prius, and the FT-EV, a small battery-electric vehicle it plans to produce by 2012.

Green Is Here to Stay

In addition to hybrid electric vehicles, automakers are experimenting with other alternative propulsion technologies, such as electric- and fuel cell-powered vehicles. For instance, Mitsubishi Motors Corp. (Tokyo) will begin selling its all-electric i MiEV later this year in Japan, while Nissan Motor Co. (Tokyo) recently unveiled a competitor called the Nuvu. Numerous startup companies located far from Detroit, such as Porteon Electric Vehicles Inc. (Portland, OR) and Tesla Motors Inc. (San Carlos, CA), are also developing a wide variety of electric vehicles.But, the recession and the credit crunch will limit the ability of any startup automaker to succeed in the short term, says Michael Omotoso, senior alternative powertrain analyst at J.D. Power and Associates (Westlake Village, CA). “The auto industry is tough-just ask the Big Three,” he points out. “Even Tesla is now struggling trying to find backing for a second model. But, long term, the right company with the right product and the right business plan can succeed in the auto industry.”

Traditional automakers such as Daimler, GM and Honda are betting on a hydrogen-powered future by pouring billions of dollars into fuel cell R&D efforts. Honda hopes to establish a leadership role in the technology, like Toyota did with the Prius hybrid a decade ago, by being the first manufacturer to offer commercially available fuel cell-powered sedans. Last year, Honda began assembling the FCX Clarity in low volumes at its plant in Takanezawa, Japan. The vehicles are currently only available to a select number of high-profile customers through a leasing program.

However, most observers believe fuel cell technology is still a few years away from widespread application in the auto industry. “Various technological problems, cost of the components and infrastructure issues hinder any [wide scale] commercialization efforts in the short term,” says Anjan Kumar, a senior research analyst at Frost & Sullivan Inc. (San Antonio). “However, with breakthroughs, we could witness fuel cell vehicles in small regional fleets [after] 2012. Mass production [will not] be possible earlier than 2015.”

According to a recent survey of senior automotive executives conducted by KPMG LLP (New York), 91 percent of respondents said hybrid systems will continue to be the main focus of automotive product innovation over the next five years, followed by electric and battery technology (82 percent). “This demonstrates that the manufacturers are recognizing clearer . . . paths to getting to market sooner, and there has been greater advancement in electric and battery technology,” says Gary Silberg, KPMG’s national advisory leader for the automotive industry.

“Despite facing recessionary times and fighting overcapacity issues, automotive executives remain focused on manufacturing alternative fuel cars,” adds Silberg. “In the next five years, automotive manufacturers are expected to [invest] heavily in new models and new technologies to satisfy consumer demand [for] fuel-efficient, affordable cars.”

Unfortunately, hybrid car sales dropped more than 50 percent in December from year-ago figures. Overall, hybrid sales were down 13 percent in 2008. Many consumers gravitated toward small, fuel-efficient vehicles equipped with four-cylinder internal combustion engines.

“The biggest hurdle is the price premium for hybrids,” says Omotoso. “The average premium in 2008 was around $6,000. This needs to be cut drastically for the green car market to take off. Honda and Toyota have announced plans to cut the premium in half over the next couple of years.”

Even if the market is still a little hesitant, many automakers and suppliers are betting on a green future. The long-term goal is to create a line of economical, fuel-efficient vehicles powered by alternatives to the traditional internal combustion engine.

“We’re in hot pursuit of anything related to fuel efficiency and green technology,” says Larry Stockline, president of Promess Inc. (Brighton, MI). His company is involved in developing the new engine that will be used in the Chevy Volt, which will be assembled at a new plant in Flint, MI. “Green cars represent new opportunities for suppliers,” Stockline points out. “I expect to see many new patents on the horizon and tremendous opportunities for entrepreneurs.”

Green Components

Many different parts play a role in improving fuel efficiency, including electric motors, inverters, batteries, battery monitoring units, continuously variable transmissions, semiconductors, sensors, cooling systems and wiring harnesses.

As manufacturers scramble to develop environmentally sensitive products, engineers will need to find innovative ways to cost-effectively assemble the new breed of components that are demanded by the green car revolution.

According to Bernd Hense, the head of Daimler’s advanced development center for powertrain and interior engineering, green car success depends on the ability of engineers to optimize components. “This will require more or less hidden components to perform new tasks,” he points out. “The only way to get the most out of the powertrain is through an optimal arrangement of the power electronics and its interaction with batteries and electric motors”

For instance, hybrids require more electric and electronic components than traditional vehicles. They employ a complex electrical architecture because they include a traditional powertrain plus an electric system that includes motors and batteries. Numerous components, such as converters, computer modules, connectors and wiring harnesses, are necessary. The battery electronic control unit is particularly important, since monitoring and control of batteries is essential for the hybrid system.

A wide variety of powertrain components will also be affected by the evolution of green car technology. “Smaller engines are required for hybrid solutions,” notes Daniel McGillis, global business development manager at ABB Robotics (Auburn Hills, MI). “These are slightly modified over current production units, with the addition of various turbo and supercharged alternatives.”

McGillis predicts that manufacturers will implement new robotic technology, such as 3D vision and force control, to replace operators in complex applications, such as transmission assembly. “On the driveline side of the market, many of the greener solutions effectively forego the market altogether with simple front-wheel-drive architectures,” he points out. “Longer term, we expect fully electric-drive motors at each wheel to replace today’s driveshaft and axle combination.”

“Overall, the lower volumes involved provide an opportunity for those with the right solution portfolio,” explains McGillis. “This new, flexible manufacturing process will closely integrate machining, cleaning and assembly into smaller cells. Robotics can be a key solution in this arena.

“Despite the seeming confusion over what the ‘winning’ green approach will be, the majority of development enterprises under way are all considering the manufacturing ramifications of their products,” says McGillis. “This cross-functional development approach is making the task of assembly more straightforward.”

The holy grail of green car technology is lithium-ion battery production. Suppliers around the world are scrambling to boost production volumes and reduce manufacturing costs.

“As a result of new technological innovations, automakers believe they have found the right batteries to power the electric vehicles-lithium-ion,” says Frost & Sullivan’s Kumar. “Venture capital investments in batteries have grown more than six times in the last five years, which is phenomenal. The challenge is to reduce both manufacturing and packaging costs.”

Several mass-production efforts are currently under way in Europe and Southeast Asia. For example, Robert Bosch GmbH (Stuttgart, Germany) and Samsung SDI (Suwon, South Korea) recently created a joint-venture called SB LiMotive. They plan to invest up to $400 million over the next four years to develop lithium-ion technology for automotive applications.

Two of the biggest players in the lithium-ion battery market, Panasonic Corp. (Osaka, Japan) and Sanyo Electric Co. (Osaka, Japan), which have a strategic partnership with Toyota, are in the process of merging their operations. Another key player, GS Yuasa Corp. (Kyoto, Japan), which is involved in a joint-venture with Mitsubishi, is currently building the world’s first mass-production assembly line for automotive lithium-ion batteries.

Concerned that the United States is falling behind other countries, a consortium of battery manufacturers recently joined forces with Argonne National Laboratory (Argonne, IL) to form the National Alliance for Advanced Transportation Battery Cell Manufacture. It hopes to build a manufacturing and prototype development center in the United States.

“A small, fragmented battery industry will not survive in the face of determined Asian competition,” warns Ralph Brodd, a battery consultant based in Henderson, NV.

A startup company called A123 Systems Inc. (Watertown, MA) just announced that it plans to build several world-class lithium-ion battery manufacturing facilities in the United States. The first assembly plant will be located near Detroit to serve customers such as Chrysler. The company has submitted an application under the U.S. Department of Energy’s Advanced Technology Vehicles Manufacturing Incentive Program to qualify for more than $1.8 billion in loans to fund its ambitious mass-production effort.

David Vieau, A123’s president and CEO, claims that the project will enable his company to supply battery systems for 5 million hybrid vehicles or 500,000 plug-in electric vehicles per year by 2013. “We’re entering an exciting new phase for the automotive industry where we increase the electrification of vehicles, reducing consumption of gasoline through advanced batteries,” Vieau points out. “This new facility would greatly accelerate this change and help ensure that the American economy replaces its dependence on foreign oil with reliance on advanced, homegrown batteries.” A

To learn more about green car technology, search for these articles at www.assemblymag.com

- Battery Manufacturing – Build It in the USA.

- Fuel Cells Face Fuzzy Future.

- In-Wheel Motors May Revolutionize the Auto Industry.

- New Players Reach for the Sky.

- Putting Cars on a Diet.

- The Hybrid Challenge.

- Traditional Technology May Zap Electric Car Market.