Manufacturers of specialty vehicles, such as trailers, truck bodies, buses and construction machinery, are increasingly using adhesives and sealants to assemble frames, panels, booms and cabs made of metal, plastic and composites. By building these components with adhesives and sealants instead of welds, threaded fasteners or rivets, engineers can reduce assembly costs, increase throughput, distribute stress more uniformly and improve aesthetics.

To prove the efficiency, durability and cost-effectiveness of adhesive assembly, we acquired a trailer frame-7 feet wide and 10 feet long-and constructed a work trailer almost exclusively using adhesives and sealants. The few fasteners that did make it into the trailer were used to temporarily hold components in place while the adhesives cured. No fasteners were used to provide structural stability.

Some adhesive applications on our trailer have already been tried and tested in the field. However, we also tried many new applications for adhesives and sealants. The end result is a tougher, more reliable, better-looking trailer that cost less to build than a conventional model.

Step by Step

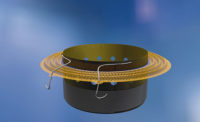

Bonding bed to frame.In traditional trailer construction, the floor is attached to the frame using mechanical fasteners, a time-intensive process that leaves the trailer susceptible to water damage.In our project, we bonded the wood floor to the frame using Loctite 5570, an elastic adhesive and sealant that distributes the load evenly over the entire frame and prevents water from leaking in through the floor panels. Only four screws per panel were required to install the entire floor. All totaled, we installed the floor in just 10 percent of the time that would have been necessary had we used fasteners alone.

Loctite 5570 is a one-part adhesive based on a modified silane polymer. The adhesive cures by reacting with atmospheric moisture. Skin formation and curing times depend on humidity, temperature and joint depth. Under normal conditions, the adhesive develops functional strength in 24 hours and fully cures in seven days.

This odorless, noncorrosive adhesive does not contain solvents, isocyanates, silicones or polyvinylchloride. Besides wood, it adheres to stainless steel, galvanized steel, aluminum, glass, fiberglass and plastics. It is compatible with most paint formulations. Resistant to ultraviolet radiation, the adhesive can be used for both interior and exterior applications.

Bonding skins to frame.The sheet-metal skin covering the sides of a trailer are usually riveted or bolted onto the frame.

Instead, we used two fast-fixturing structural acrylics: Loctite H4500 and H8600. During the cure process, we used screws to fixture the skin in place. By bonding the skins to the frame with adhesive, 90 percent fewer fasteners were needed for assembly, resulting in a better looking, stronger, more leak-resistant trailer. This same process was used to bond the door and roof skins.

Loctite H4500 is a highly thixotropic, two-part methacrylate adhesive for bonding metals, such as steel, stainless steel and aluminum. It also bonds epoxy-coated metal, sheet-molding compound and many plastics. The adhesive bonds to metals without a primer. It contains a corrosion-inhibiting additive to ensure long-term bond durability even when exposed to moisture. Mixed at a ratio of 10-to-1, the adhesive reaches fixture strength in 15 to 20 minutes at 70 F.

Loctite H8600 is two-part methacrylate for structural bonding of galvanized steel. Mixed at a ratio of 2-to-1, it reaches fixture strength in 55 minutes at 72 F. This toughened adhesive has a high peel strength. A thick material, it can be applied to vertical surfaces without sagging.

Seam sealing the frame and skins. On standard trailers, polyurethane or silicone caulks seal gaps and prevent water penetration. These sealants work well, but they will yellow over time and do not last long in the harsh environment of the road.

On our trailer, we used Loctite 5510 to seal gaps in the frame and all the skins, including the door and roof. Like the adhesive we used to bond the floor, Loctite 5510 is a one-part adhesive based on a modified silane polymer.

Free of isocyanates, solvents and silicones, this low-odor, highly flexible sealant resists vibration, movement and impact. Because it is impervious to UV light, the sealant will not degrade or crack over time. It fixtures quickly and can be color-matched to the skins for seamless assembly.

The adhesive cures by reacting with atmospheric moisture. It develops functional strength in 24 hours and fully cures in seven days, but these times can be shortened by increasing exposure to moisture.

Bonding and sealing panel trim.The panel trim located around the trailer’s frame was bonded using Loctite H4500 and 5570. Panel trim is normally riveted in place, then sealed with polyurethane or silicone caulks. The adhesives in our project simultaneously bond and seal trim materials, even in critical areas such as wheel wells. While fasteners were still needed to help secure the panel trim, the use of adhesive reduced the number of fasteners by 90 percent and shortened assembly time by 40 percent.

Bonding diamond plate and nose to skins.On a traditional trailer, the diamond plate is riveted onto the trailer skin, while the nose is bolted or riveted in place, then sealed with caulk. On our trailer, the diamond plate was bonded with Loctite H4500, eliminating mechanical fasteners altogether. The adhesive unitized the assembly, eliminating any potential for rattling and producing a higher quality appearance.

For the nose assembly, we used the same structural adhesive to bond and seal the nose to the skins, eliminating rivets. Because the nose assembly on our trailer came with predrilled holes, screws had to be inserted to prevent leakage. Still, bonding reduced assembly time by 20 percent and fastener count by 30 percent. In the future, the nose assembly could be redesigned to eliminate predrilled holes, thereby eliminating the need for fasteners.

Bonding internal brackets.Most trailer interiors have galvanized steel brackets for tying down cargo. Ordinarily, we would have secured the bracket plate to the trailer walls using two screws per frame member. The bracket itself would have been secured to the plate using 200 screws.

Instead, we used Loctite H4500 to bond both the plate and the bracket. As a result, we needed only one screw per frame member to fixture the bracket plate, and we needed just 20 screws to install the bracket. Assembly time was 70 percent faster using adhesives, and stress is distributed evenly along the length of the bracket, making it more durable. Adhesive bonding reduced fastener use for this application by 90 percent.

Threadlockers for miscellaneous hardware.For the limited number of threaded fasteners on our trailer, we applied Loctite 2033 threadlocker to prevent vibrational loosening and seizing. This medium-strength gel adhesive locks and seals threaded joints ranging from 0.25 to 1 inch in diameter. It cures in the absence of air between close-fitting metal surfaces. It resists most chemicals, liquids and gases.

Usually, the trailer floor is attached to the frame using mechanical fasteners. Henkel engineers bonded the wooden floor panels to the frame using a one-part modified silane polymer adhesive. The engineers installed the floor in just 10 percent of the time that would have been necessary had they used fasteners.

The Results

The trailer was completed in April 2008. Since then, it’s been on the road, hauling a motorcycle and an all-terrain vehicle throughout the country. The exterior of the trailer is decorated with graphics that were applied without concern for the placement of metal fasteners. As of January 2009, the trailer has logged 7,000 miles and experienced no problems with structural integrity or leakage. In early February, the trailer started a tour of manufacturing locations along the East Coast.For videos of each step of this assembly project, visitwww.gluemytrailer.com.