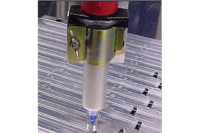

ProTech labels absorb undesirable noises

emanating from buckles and reduce the mechanical stress of their individual

components. Photo courtesy Schreiner ProTech North America Inc.

Seat belts reduce the overall risk for serious injuries in crashes by 60 percent to 70 percent and the risk for fatalities by about 45 percent. In noncollisions, mainly rollovers, the reduction in fatalities is about 75 percent.

Autoliv has been manufacturing seat belts since 1956, and was first in the world with three-point belts in 1959. Autoliv also pioneered the three-point retractor belt in 1967 and the seat belt pretensioner in 1986. The company and its joint ventures and licensees produce more than 110 million seat belt systems annually.

Nevertheless, Autoliv recently faced a new challenge related to its seat belts. Individual components within the buckle were hitting against each other and making a rattling noise during engagement, as well as when vehicles were in motion.

Autoliv turned to Schreiner ProTech North America Inc. to find a way to reduce that noise.

Schreiner ProTech developed noise-control labels that absorb undesirable noises emanating from buckles and reduce the mechanical stress of their individual components.

Self-adhesive die-cut parts, the labels are made of a specialty composite and feature a velour surface that meets automotive interior requirements for resistance to abrasion and sunlight. The labels are visually attractive and come in different shapes to suit the ergonomic needs of Autoliv’s customers. The labels are delivered on rolls for fast, reliable and cost-efficient application to the seat belt component.

For more information on seat belt noise control, call 888-888-8564 or visit www.schreiner-protech.com.