Lockheed Martin has automated the process of painting F-35 Lightning II jets at its Raleigh, NC, plant. Photo courtesy Dassault Systèmes

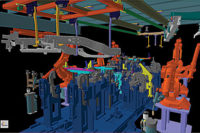

The F-35 jets are now painted in robotic workcells that are programmed using DELMIA simulation software by Dassault Systèmes. As long-time users of DELMIA simulation products, Lockheed Martin engineers were already familiar with the software, making it easy for them to move into robot support roles.

Lockheed Martin uses the software to verify that robots reach all the painting positions while avoiding any collisions.

DELMIA allows manufacturers in any industry to virtually define, plan, create, monitor and control all production and assembly processes. The software helps companies maximize production efficiency, lower cost, improve quality and reduce time to market. DELMIA also offers a collaborative platform throughout the entire production process for engineers of all disciplines and suppliers.

Currently, Lockheed Martin uses the software in two different automated paint cells, both configured on moving rail systems. A three-robot cell is dedicated to painting the aircraft exterior, and a two-robot cell is configured to handle a variety of F-35 components.

Lockheed Martin uses DELMIA simulation software to verify that robots reach all the painting positions while avoiding any collisions. Photo courtesy Dassault Systèmes

Equally important, Fastsurf lets Lockheed Martin monitor the thickness of coatings through a query option at any point in the application. Applying coatings at the correct thickness is critical to ensuring that aircraft meet design requirements.

“Their [Lockheed Martin] in-depth experience in robotic off-line programming was key in shaping a production-hardened solution with aerospace accuracy,” says Niall Cullen, Cenit account manager.

Other key features of DELMIA are an intuitive 3D user interface and a use-only Web connection. The interface improves production process efficiency by lowering costs and reducing errors. Manufacturers use the Web connection for authoring and collaborating on manufacturing processes.

For more information on robotic simulation software, call 248-267-9696 or visit www.3ds.com.