“Trust in God, but keep your powder dry.” That was good advice to riflemen in the 1800s, and it still applies today. These days, however, gunpowder is protected from the elements inside a cartridge that’s been sealed with a high-tech adhesive.

A modern cartridge consists of the bullet itself; the case; the propellant; the rim, which aids in loading; and the primer, which is located at the bottom of the case and ignites the propellant. The primer consists of small metal cup, a small amount of an explosive compound, and a triangular piece of metal called the anvil. When struck by the firing pin, the center of the cup collapses, pressing the explosive against the anvil. The explosive ignites and shoots a flame into the case, igniting the propellant and expelling the bullet.

During assembly, the primer is pressed into a hole at the base of the case. The primer must be flush, or the cartridge will not feed correctly in the magazine. After the case is filled with propellant, the bullet is pressed into the case and crimped in place.

To keep moisture from spoiling the propellant, a sealant must be applied between the bullet and the case. In the past, this sealant was applied inside the case before the bullet was inserted. The sealant “was an emulsion, like a black tar,” explains Larry Henderson, president of L-Tech Enterprises Inc., an ammunition assembler in Eubank, KY.

This material presented three problems for L-Tech. First, because the sealant was applied before the bullet was inserted, the company could not assemble cartridges if a problem arose with the material or the dispensing process. “With the [emulsion], you had to insert the bullet within a short period of time after it was applied,” says Henderson.

Another issue was that the quality of the seal depended on how accurately the bullet was pressed into the case. If the bullet scraped against the inside wall of the case, a leak path could be created. Finally, dispensing the material accurately was difficult with small caliber ammunition. “With the smaller cartridges, we just couldn’t get it to seal,” says Henderson.

As between the bullet and the case, a sealant also has to be applied between the case and primer to prevent moisture from compromising the explosive. For this task, L-Tech had been using a solvent-based material, which could be put on after the primer was inserted. The problem with that material, however, was its cure speed. L-Tech wanted a sealant that cured instantly and did not contain volatile organic compounds. As lethal as its products may be, L-Tech wanted an eco-friendly assembly process.

At the bullet sealing station, the cartridges pass beneath a dispensing valve equipped with a medical-grade needle. The needle is positioned at an angle to the cartridges. Its beveled tip is just above the junction between the bullet and case, but does not touch the cartridge. Photo courtesy Hernon Manufacturing Inc.

A Good Seal

For help, L-Tech turned to Hernon Manufacturing Inc., a supplier of adhesives, sealants, dispensing machines and curing equipment. Based in Sanford, FL, the company has been working with ammunition manufacturers for years, including ATK, General Dynamics, Remington, Winchester, IMI and the Chemring Group.For the junction between the bullet and the case, Hernon provided its External Bullet Sealant 59541, a single-component, solvent-free, dual-curing anaerobic adhesive. Applied after assembly, this toughened material wicks down between the bullet and the cartridge case in less than 5 seconds. Once inside the joint, it reaches fixture strength in less than three minutes. Any adhesive that remains outside the joint cures in seconds when exposed to ultraviolet (UV) light. Full strength is reached in 24 hours.

The material has good gap-filling properties and maintains a seal even under full vacuum. When fully cured, the adhesive is a thermoset plastic that resists most solvents and withstands temperatures ranging from -65 F to 400 F.

“That material just wicks right around the cartridge,” says Henderson. “It’s been working really well.”

For the junction between the primer and the case, Hernon provided its Ammunition Primer Sealant 59621. Like the bullet sealant, the primer sealant is a low-viscosity, single-component, dual-curing anaerobic adhesive. It, too, is applied after assembly, penetrating the joint by capillary action and curing quickly in the absence of oxygen. Adhesive that is not drawn into the joint is cured via UV light.

The material cures quickly at room temperature without the need for surface activators or heat. Fixturing strength develops in two to three minutes, or within 10 seconds by exposing the joint to high-intensity, long-wavelength UV light (365 nanometers). To ensure full curing, the UV light irradiance should exceed 60 milliwatts per square centimeter. Full strength is reached in 24 hours.

To aid in inspection, Hernon adds a fluorescent dye to the sealants. The dye glows under UV light, enabling a vision system to detect whether the adhesive has penetrated the entire joint. “It makes inspection much simpler,” says Henderson. “We also use a high-intensity black light to manually inspect any cartridges that are kicked out by the automatic inspection system.”

Formulating the sealants was a challenge. “The sealants must have enough viscosity to stay where they are dispensed, but also be thin enough to wick into the joints,” says Tom Bray, engineering manager at Hernon.

The materials also have to create a good seal without impairing the performance of the cartridge when fired. Hernon’s adhesives and sealants meet a number of military specifications, including MIL-A-46106A, MIL-A-46050C, MIL-I-17563C, MIL-R-46082B, MIL-S-22473E, and MIL-D-46163A.

At the primer sealing station, a second valve-equipped with a curved needle-dispenses a dot of sealant on the primer. The needle must contact the cartridge to apply the sealant. Photo courtesy Hernon Manufacturing Inc.

High-Speed Dispensing

If developing a good bullet and primer sealant is akin to putting a round or two into the X ring from 50 yards, then designing a system to dispense that material at the speeds and accuracies necessary for high-volume ammunition assembly is like going 10 for 10.Hernon’s Auto Sealer 5000 is designed specifically for dispensing and curing sealants on pistol and rifle ammunition, including blanks. The system applies sealant to both the projectile and the primer at speeds in excess of 200 rounds per minute.

Assembled cartridges are fed into the system from a large vibratory bowl. From the bowl exit, the cartridges slide onto a custom-made chain conveyor that resembles the treads for a tank or bulldozer. Each link in the chain contains an open slot to hold one cartridge. The cartridges are placed on the conveyor perpendicular to the direction of travel, with the tip of the bullet facing the opening. As the conveyor moves, the cartridges roll in place like roller bearings.

At the bullet sealing station, the cartridges pass beneath Hernon’s Sure Shot 3200 dispensing valve equipped with a medical-grade needle. The digitally controlled valve is driven by a servomotor. The needle is positioned at an angle to the cartridges. Its beveled tip is just above the junction between the bullet and case, but does not touch the cartridge.

As a cartridge rolls beneath the needle, a single drop of sealant is applied to the joint. The rolling action of the cartridge ensures that the sealant is evenly distributed around the entire joint. The amount dispensed is accurate to within ±0.5 microliter.

At the primer sealing station, a second Sure Shot 3200-equipped with a curved needle-dispenses a dot of sealant on the primer. Unlike the previous station, the needle must contact the cartridge to apply the sealant.

That requirement was a challenge, says Bray. Given the low viscosity of the sealant, moving the needle up and down at 200 cycles per minute tended to send drops flying before they reached the primer. Hernon’s engineers solved the problem by moving the needle in an oscillating path, rather than straight up and down.

At the next station, the cartridges roll past two UV lamps. The lamps both cure the sealants and serve as a light source for a pair of machine vision system, which check the integrity of the seals.

The system can handle a range of different sizes, from .22- to .762-caliber. Tooling changeover can typically be accomplished in 30 to 60 minutes. One feeder bowl can accommodate three ammunition sizes.

To see the Auto Sealer 5000 in action, clickhere.For more information on adhesives, sealants, dispensing machines and curing equipment, call Hernon at 407-322-4000 or visitwww.hernon.com.

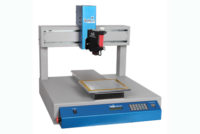

The Auto Sealer 5000 applies sealant to both the projectile and the primer at speeds in excess of 200 rounds per minute. Photo courtesy Hernon Manufacturing Inc.

ASSEMBLY ONLINE

For more information on dispensing, visit www.assemblymag.com to read these articles:•Assembly Showroom: Hernon Manufacturing.

•Assembly in Action-Dispenser Improves Assembly Process.

•Dispensing: Better From the Benchtop.