Despite recent inroads by aluminum, copper will remain the dominant material used in automotive wiring harness applications over the next few decades. That’s

|

Jump to: High-Copper Alloys Numerous Benefits Flex Life |

because harness weight can easily be reduced by using finer wires wherever electrically feasible.

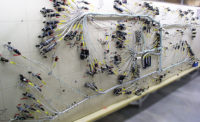

Wiring harnesses can account for more than 60 pounds of body weight in cars and light trucks powered by internal-combustion engines. That figure is multiplied several times in electric and hybrid vehicles, which are expected to become more popular in the next 10 years. In fact, even high-end sportscars are jumping on the bandwagon.

At last month’s Geneva International Motor Show, Ferrari unveiled the most advanced and powerful vehicle it has ever developed. The LaFerrari coupe does 0 to 60 mph in less than 3 seconds and produces 963 hp. It is Ferrari’s first gas-electric hybrid, featuring both a V12 engine and a 120-kilowatt electric motor. Engineers at Delphi Automotive developed wiring harnesses for both the low- and high-voltage systems of the vehicle’s electrical-electronic architecture.

To reduce vehicle weight and improve fuel efficiency, automotive engineers around the world are adopting lighter materials, such as aluminum, carbon-fiber composites and magnesium, for many applications. For example, replacing copper wiring with aluminum can reduce the weight of harnesses. However, there are several drawbacks:

- Aluminum conductors are weaker and less fatigue-resistant than copper wires of comparable size, making breakage more likely.

- Aluminum and some of its alloys tend to creep (slowly deform) under low stress. When combined with the metal’s 42 percent higher thermal expansion coefficient compared with copper-based metals and the cyclical nature of automotive temperatures, this tendency causes aluminum-brass and aluminum-copper connections to loosen over time.

- Aluminum loses strength rapidly at even moderately elevated temperatures. And, the metal’s lower volumetric electrical conductivity— only 62 percent that of copper— requires larger-diameter conductors for equivalent ampacity, which makes harnesses more difficult to install.

- Aluminum is more difficult to crimp reliably. Its corrosion resistance, particularly to dissimilar metals, is significantly lower than that of copper-base metals.

High-Copper Alloys

Harness weight can easily be reduced by using finer wires wherever possible. This option exists because fine-gauge conductors are commonly oversized beyond electrical requirements to reduce the risk of breakage when multistrand harnesses must be pulled through tight feed-throughs.

A broken conductor is very costly at that stage of the assembly process. If a break is detected, the damaged harness must be removed and scrapped. If it gets into the field undetected, the electrical malfunctions it causes can create safety problems. At the very least, it reduces the vehicle’s perceived reliability.

Alloying copper cables to raise strength would appear to be a reasonable solution. However, adding alloying elements reduces electrical and thermal conductivities. This is true for all metals, including copper and aluminum. The severity of the reduction varies with the species and amount of elements added, as illustrated in Figure 1.

In the simplest copper alloys, alloying elements are present in solid solution as a more or less uniform single phase. The differently sized solute atoms distort the phase’s crystal lattice, which adds strength, but also lowers conductivity.

Within limits, the higher the alloy concentration, the greater will be the reduction in conductivity, as illustrated in Figure 2. The effect is additive when more than one alloying element is present. Losses are slightly less severe in fully hardened heat-treatable alloys, since hardening creates precipitates that remove atoms from solution. But, in general, higher strength usually comes with a reduction in conductivity.

The alloy designer’s challenge is, therefore, to achieve a practical balance between strength and conductivity at an acceptable cost. The end user’s challenge is to select the alloy that offers the most suitable strength-conductivity compromise, taking into account such additional factors as product form (rod, wire or strip), ductility for adequate formability, corrosion risk, service temperature and cost.

Developing improved alloys is an ongoing pursuit among copper fabricators thanks to the electrical and electronics industries and increasingly stringent requirements from automotive, aerospace and military manufacturers. The resulting body of research has yielded scores of new alloys, including high-copper alloys. These unique materials combine high tensile strengths and higher electrical conductivities than those offered by any realistically alternative metals, including aluminum. They also exhibit copper’s intrinsic corrosion resistance.

Numerous Benefits

Wrought forms of high-copper alloys contain between 96 percent and 99.3 percent copper, including silver, a beneficial residual impurity (cast high-copper alloys contain a minimum of 94 percent copper and silver). They are assigned unified numbering system designations from C16000 to C19999, arranged in four parts:

- Alloys in Part 1 include cadmium copper, beryllium coppers and several multi-constituent coppers, many of which can be heat-treated for maximum strength.

- Part 2 alloys include the chromium-coppers, chromium-zirconium and zirconium-titanium coppers, plus free-machining copper and a variety of complex alloys. Many of these alloys are also heat-treatable.

- Part 3 alloys contain iron, nickel, tin and silicon in various combinations. Some contain silver for elevated-temperature strength and lead to improved machinability.

- Part 4 alloys rely primarily on combinations of iron, tin, zinc and phosphorus for improved mechanical properties. Some are leaded, as well.

Included among the high-copper alloy family are a small group of materials that deserve mention as potential candidates for automotive wires even though they are not often used in wire form. Technically, they are not even copper alloys; rather, they belong to a separate category of structural materials known as metal-matrix composites (MMCs) and, incorrectly, as dispersion-strengthened “alloys.”

They consist of a nearly-pure copper matrix containing a small amount of extremely fine aluminum oxide (alumina, Al2O3) particles that function just like the metallic precipitates that strengthen heat-treated alloys. The difference is that there are no conductivity-lowering alloying elements present. Thus, strength, conductivity and elevated temperature resistance remain high. Corrosion resistance is close to that of pure copper.

The materials have been used for decades as high-performance (RWMA Class III) resistance-welding electrodes and in electrical and electronic products that require high conductivity and long-term elevated-temperature resistance. They can be drawn into fine wires, although high-alumina content grades present some difficulties. For that reason, only C15720 (0.2 percent aluminum as Al2O3) is included here.

High-copper alloys are primarily used in high-performance electrical and electronic connectors and components, either as wire (pin-type connectors, windings and conductors for elevated-temperature service) or strip (flat terminals or lead frames). The alloys are listed under SAE specifications J461 and J463 and ASTM specifications B1, B2, B3 and B47.

Flex Life

Inadequately strong or poorly supported wires can flex and fail in fatigue under loads imposed by the movement of connected components. Vibration and strength-lowering elevated temperatures can also increase the likelihood of failure.

Individual scenarios are difficult to quantify and almost impossible to simulate in accelerated tests for prequalification testing. Nonetheless, ASTM B470-02, Standard Specification for Bonded Copper Conductors for Use in Hookup Wires for Electronic Equipment, also referred to as the “Flex Life” test, has become a widely used and internationally recognized method to measure the fatigue resistance of electrical and electronic conductors.

Results are necessarily qualitative, although the test does provide a repeatable comparison of various conductor materials under user-defined tensile load conditions. The test consists of repeatedly spooling and unspooling a weighted wire around a mandrel. The mandrel diameter, angle of wrap, wire diameter, test temperature and tensile load are fixed by the operator.

A 2011 study conducted for the German Copper Institute (DKI) with support from the International Copper Association used a modified version of the ASTM B470-02 test method to evaluate the flex life of 20 copper alloys, including a number of high-copper alloys, plus an aluminum-base wire alloy, copper-clad aluminum and copper-clad steel. Wires were tested at room temperature and at 105 C, in addition to several bend angles and bend radii. Alloys tested by DKI included CuETP/C11000; CuAg0.1/C11600; CuSn0.15/C14415; CuCr1Zr/C18150; CuMg0.14/C15500; and CuCrAgFeTiSi/C18080.

Figure 3 compares the failure lifetimes of alloys at a bend radius of 5 millimeters and bend angles of 60 and 90 degrees. One would expect that cycles to failure at a bend radius of 60 degrees would be at least as high, or higher, than those at a radius of 90 degrees. This is true for all alloys except alloy CuZr37 R1044, a yellow brass. The black diagonal line in the figure represents a slope of 1.0.

Among the high-copper alloys, highest bend lifetimes were attained in alloys C18150 (CuCr1Zr) and CuMg0.14, which approximates C15500, but contains phosphorus and silver in addition to magnesium. Alloy C18080 (CuCrAgFeTiSi) also performed well. These alloys appear to display the combinations of bend life, tensile strength and conductivity needed in small-gauge automotive electrical wires. However, the widely varying requirements posed by individual applications limit the value of straightforward rankings, and alloys should be selected on a case-by-case basis.

For all test conditions included in the DKI study, the aluminum and copper-clad aluminum wires exhibited the lowest flex lifetimes (red data point at the lower left in Figure 3). But, they should be used with caution, if at all, in situations where fatigue may be an issue. Copper-plated steel wires exhibited the highest flex lifetimes, but their electrical conductivity is considerably lower than any of the copper-base alloys and their weight (density) is considerably higher than that of aluminum.

Based on the highly favorable combination of tensile strength and electrical conductivity offered by the high-copper alloys, in addition to their resistance to bending fatigue, it appears that high-copper alloy would provide viable alternatives to copper itself in highly stressed or fatigue-prone automotive wiring harnesses.