For mass-production on assembly lines, UV- and light-curing adhesives offer significant advantages over other joining methods.

They are generally solvent-free and one-component materials, so they can be integrated into continuous manufacturing processes safely and easily. Because they polymerize in seconds when exposed to ultraviolet or visible light, they won’t compromise cycle time in automated assembly processes. Curing with light is much less energy-intensive than curing with heat.

Curing occurs with deliberate exposure to light of a certain wavelength, not just any light, so components can be positioned precisely before the adhesive hardens. The adhesives can bond components that are too small to be screwed together. And finally, they have outstanding optical qualities. When bonding layers in a touch screen, they can reduce reflections and improve readability, even in direct sunlight.

There are two main types of UV-curing adhesives. Radically initiated adhesives are usually based on an acrylate matrix, while cationically initiated adhesives are based on epoxy resins. These one-component adhesives are simple to process. No mixing is required. In addition, both types of adhesive are available in dual-curing formulations. These materials usually cure with a combination of light and heat or humidity. This ensures that the adhesive will cure in areas that cannot be directly illuminated by light.

For both chemistries, it’s essential to match the wavelength of the UV light source with the trigger of the photoinitiator to ensure an effective curing reaction. Light sources based on LEDs are favored, because their peak emission spectra match the wavelengths needed to activate the photoinitiators. LED lamps are available with different wavelengths to suit a range of adhesives and photoinitiators.

Bonding Automotive Switches

Light-curing adhesives are particularly well-suited for high-volume assembly processes, where rapid curing and high reliability are essential. The following examples illustrate the range of applications for UV-curing acrylate- and epoxy-based adhesives.

In the automotive industry, process reliability is important for assembling safety-critical devices, such as air bag deactivation switches and seatbelt monitoring switches. Because these devices are produced in the millions on high-speed automated assembly lines, they require an adhesive that is easy to dispense and fast-curing. Process control is essential. Because they are more cost-effective and reliable, light-curing adhesives are increasingly being used in place of two-component or heat-curing adhesives and casting compounds.

When assembling these snap-action switches, hermetical sealing of the housings and connectors is essential for withstanding environmental conditions during vehicle operation. It’s often necessary to bond the housing and seal the connector pins in a single step, a process known as seal bonding.

Two-component or heat-curing adhesives and encapsulants are neither particularly reliable nor cost-effective for such applications. The complex and high-maintenance equipment for processing two-component adhesives work only when large amounts (more than 100 milligrams) are dispensed.

In contrast, UV- and light-curing adhesives are optimized for bonding auto parts and sealing them against fluctuating temperatures, humidity, contaminants, pressure and shocks. (Light-curing adhesives for such applications remain flexible over a temperature range of -40 to 176 F.) The operating costs of curing lamps are much lower than those of heat-curing ovens. Light-curing adhesives are easy to dispense in high-volume automated assembly lines. Their constant viscosity and unchanging flow properties facilitate complete wetting of the parts, which leads to a

reliable seal. The adhesives cure within seconds—much faster than thermal curing—and the bond holds up exceptionally well through years of use.

In addition, 100 percent in-line control of seal tightness is possible, since acrylate-based, UV-curing adhesives achieve final strength immediately after irradiation. Fully automated camera inspection of the bond can be done in-line by using colorants or fluorescent agents in the adhesive, ensuring detection of insufficient adhesive or possible contaminations at the connector pins.

Smart Phone Assembly

Light-curing adhesives have played an important role in the rapid improvement of smart phone technology, having met the demand for a fast, easily automated joining method for assembling displays, speakers and other components.

These adhesives enable tension-free, direct bonding of the cover glass to the LCD module (display bonding) and to the touch panel (touch-to-lens bonding) with high optical transparency. To minimize tension between substrates, which could cause display failures, these adhesives are soft and flexible—with a shear modulus around 30 times lower than a standard acrylate formulation.

Dual-curing adhesives are available for displays with shadowed areas (for example, black print edges). They cure with exposure to both light and moisture.

What applies to a smart phone’s display also applies to its speakers. They are getting smaller and must be produced at high volumes with high quality. Today’s mobile phones include high-performance mini-speakers, comprised of membranes, coils and covers—up to eight components—bonded together with a light-curing adhesives.

With light-curing adhesives, these tiny speakers can be mass-produced at rates of up to 6,000 per hour. Testing can be done immediately after curing, so OEMs do not need a buffer stock to ensure just-in-time delivery.

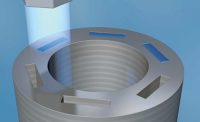

Billions of microchips are embedded in credit cards, bank cards and SIM cards for mobile phones. Production of these cards and microchips requires a fast and reliable encapsulation

process. Epoxy-based, light-curing adhesives offer an ideal solution. A high-viscous dam compound is quickly dispensed around the chip. Then the chip is encapsulated by a less-viscous fill compound. Curing both materials takes seconds. The flow properties of both encapsulants are particularly important, since the chip is placed in a cavity and a maximum cover height must not be exceeded. Light-curing adhesives maintain this tolerance exceptionally well.

For more information on UV-curing adhesives, call 978-254-5275 or visit www.delo-adhesives.com/us.

Comparing UV-Curing Chemistries

Acrylate-Based Epoxy-Based

Extremely fast curing Thermal resistance

High-peel resistance Chemical resistance

Optically clear Low outgassing

UV-stable Optically clear

Universally good adhesion Resists yellowing

High equalization of tensions Dry-surface preactivation possible