Mentor, OH-based IT Plastics specializes in potting and encapsulation of electronic assemblies, sensitive circuitry and devices for OEMs, engineers and product-design firms. Founded in the late 1980s, the company excels in applications requiring polyurethane materials.

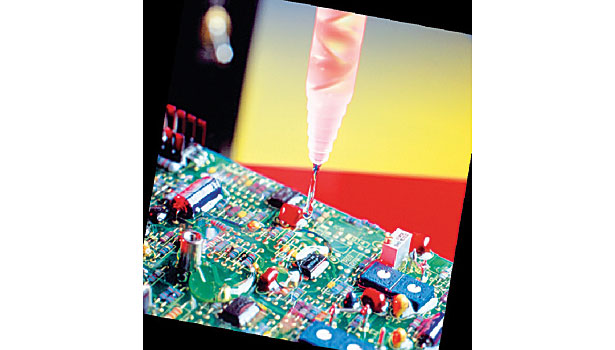

IT’s potting and encapsulation services include material selection and testing, prototype design and fabrication, production and vacuum potting, and mold fabrication. The company also performs overmolding, Federal Information Processing Standard molding, battery pack sealing and product assembly.

In 2012, an OEM presented IT Plastics with a challenging application. The manufacturer needed a potting material that maintains its properties in a broad range of operating temperatures, withstands high humidity and is unaffected by moisture at high temperatures for long periods of time.

IT Plastics turned to Epoxies Etc., a leading formulator of epoxies, urethanes and silicones, for help. Its adhesives, potting compounds and coatings are widely used in the electronic, electrical, construction and decorative industries.

Engineers from both companies discussed the application and recommended the OEM test the effectiveness of Epoxies Etc.’s 20-2350 electronic-grade polyurethane potting compound. After rigorous testing, John Schriner, president of IT Plastics, reported that the compound met all performance requirements. It is still being used, and the two companies have since collaborated on several other projects.

Compound 20-2350 is formulated to provide insulation, moisture resistance and flexibility at low temperatures. Its wide operating temperature range (-40 to 125 C) produces low stress on sensitive components.

The compound has a viscosity of 1,600 centipoise at 25 C and a hardness of 50 Shore A. Its glass transition temperature—the point at which the compound becomes hard and brittle—is -72 C. Clear in color, 20-2350 comes in 5-gallon pails, has a 10-to-1 mix ratio and is applied with a meter-mix dispensing system.

For more information on potting and encapsulating compounds, call 800-376-9437 or visit www.epoxies.com.