Microsecond fiber lasers have been used successfully to cut hypotubes and stents for many years. While these lasers are precise and fast, they have a downside. Parts cut with them require several post-processing operations, which add cost and can damage delicate parts.

Now, a new technology, disk-based femtosecond lasers, has been introduced that promises to solve that problem. These lasers produce ultra-short pulses—less than 400 femtoseconds—that leave no thermal fingerprint on the part. A femtosecond is 10-15 second. A 300-femtosecond laser pulse is just 90 microns long.

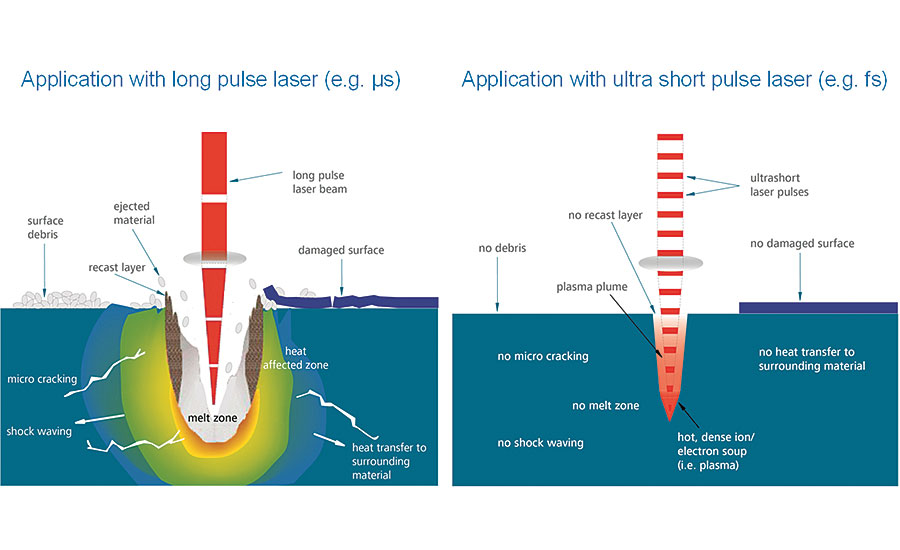

Due to their high peak power, femtosecond lasers cut by cold ablation rather than melt ejection. As a result, they can cut very fine details, and parts require minimal post-processing. Femtosecond lasers produce no melting or thermal tension in the material and no change to the material’s characteristics. They do not produce microcracks, recast layers or debris, so part surfaces are smooth and clean.

Originally developed for wafer dicing and scribing solar panels, femtosecond lasers are now being used to cut and mark plastic, metal, glass and ceramics in medical device applications.

The edge quality possible with a femtosecond laser makes it ideal for machining of stents (both nitinol and cobalt-chrome), catheters, heart valves, and polymer tubing. Fine features can be cut into the thinnest material, while still maintaining mechanical and material integrity. No internal water cooling is needed for even the smallest diameter nitinol tube.

Although femtosecond lasers remove material more slowly than fiber lasers, overall processing time is faster, since there’s no need for post-processing. For example, producing a coronary stent with a fiber laser is a multistep process. After the part has been machined with the laser, it must be honed and deburred. Then, a chemical etch process must be performed to clean up around the edges. Finally, the part undergoes electropolishing.

Not only are these steps time consuming, but they can also cause the part to deform, become brittle and develop micro cracks. Yields tend to be in the 70 percent range.

In contrast, machining with a femtosecond laser is a dry process that does not heat the part. Once the part is machined, it undergoes an electrochemical process to round the edges. The integrity of the part is improved and yields can be closer to 95 percent.

The femtosecond laser is also the only technology available for machining medical components out of new bioabsorbable polymers. An alternative to traditional polymers or metals, these next-generation materials (also called aspirants) can be safely implanted for controlled lengths of time before being absorbed by the body.

Bioabsorbables are already being used for coronary stents in the European Union, although they have not yet received FDA approval for use in the U.S. Mostly composed of polyesters, primarily homopolymers and copolymers of polylactic acid and polyglycolic acid, bioabsorbables are showing promise for a variety of uses, including cardio stents for patients who may have been stented numerous times and can no longer tolerate a traditional fixed stent. The material is also being used to deliver medicines to organs, such as the liver.

Bioabsorbable materials can be machined into any profile that can be used for stents. However, it must be machined without inducing heat. Overheating could lead to crystallization in the material, which would degrade its structure, reduce its lifespan, and adversely affect its ability to dispense medicine at the correct rate. Also, because bioabsorbables dissolve, they cannot be cleaned like most plastics, nor can they be exposed to liquids.

For more information on femtosecond lasers, visit www.amadamiyachi.com