Officially, UTC Aerospace Systems is only 3 years old—the result of a merger between Goodrich and Hamilton Sunstrand. In reality, however, the company’s aerospace roots go back more than a century.

Goodrich opened its doors in 1909 and provided tires for many of the first planes built in the United States. One year later, Thomas F. Hamilton and Paul J. Palmer founded Hamilton & Palmer (which evolved into Hamilton Sunstrand) and started building gliders and seaplanes in Seattle.

Today, as a result of the merger, UTC is one of the world’s largest suppliers of technologically advanced aerospace and defense products. Headquartered in Charlotte, NC, the company designs, manufactures and services systems and components used in commercial, regional, business, and military aircraft and helicopters. It also serves as a supplier for unmanned aerial vehicles, ground and naval vehicles, satellites and international space programs.

The company currently operates 150 sales and manufacturing sites in 26 countries, with half of these sites located outside the United States. Arizona is home to facilities where interior lighting systems and engine components are assembled.

A common problem at these and similar facilities is the presence of static electricity, which can cause electrostatic discharge (ESD) and damage sensitive components or data stored on electronic devices. To eliminate its ESD problem at one Phoenix facility, UTC recently installed more than 100,000 square feet of StaticStop flooring made by SelecTech Inc.

The flooring generates a maximum of only 7 volts of static electricity when someone walks on it. This number is much less than the 100 volts allowed by the ANSI/ESD S20.20 standard. UTC also likes StaticStop because it prevents moisture from forming on the concrete slab beneath the floor. It’s ergonomically comfortable and easy to maintain.

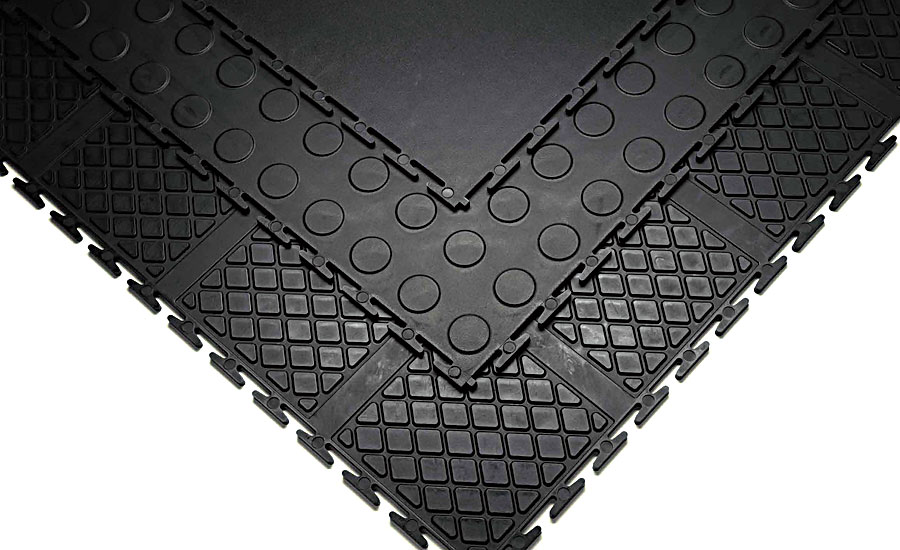

The flooring features a unique interlocking tab system that allows quick installation without the need for adhesives, copper strips, underlayments, padding or surface preparation. In addition, downtime is minimized or eliminated because machinery does not have to be moved or removed for installation.

StaticStop is cost-effective in several other ways as well. It’s durable enough for industrial environments, including fork truck traffic, and scalable for simple or intricate layouts. Plus, the flooring is 100 percent recyclable and manufactured with a minimum of 20 percent recycled materials.

SelecTech also offers several other types of ESD flooring. SelecTile has a free-floating surface with an interlocking tab system. FreeStyle flooring also interlocks, but is decorative, grounded and does not require any conductive rejuvenators or wax. FreeStyle PLUS comes with a polyurethane or ceramic finish and is also available as a glue-down tile. FreeStyle CVT is direct glue-down conductive vinyl tile.

For more information on anti-static flooring, call 508-583-3200 or visit www.selectechinc.com.