As plastic medical devices get smaller and more intricate, engineers have fewer options for assembling them.

Friction-based joining processes, such as ultrasonic welding, spin welding and vibration welding, work fine for most assemblies, but they can also generate particulates, and that’s a no-no for some medical devices. For example, the fluid channels inside a blood test cassette might be a millimeter wide. Even small particulates could impair the cassette’s performance.

Laser welding solves that problem. “The overriding reason medical device manufacturers choose laser welding is that it’s a clean joining method,” says Hugh McNair, manager of laser applications and systems at Branson Ultrasonics Corp. “It does not generate particulates.”

Branson is one of several suppliers of laser plastic welding technology, including Dukane Corp., LPKF Laser & Electronics, and Leister Technologies LLC.

Branson’s process—simultaneous through-transmission infrared laser welding—is unique. Multiple diodes produce laser light at a wavelength of 990 nanometers. Fiber-optic bundles transmit the light through a waveguide that uniformly distributes energy to the entire joint line simultaneously. (In other technologies, the laser traces or scans the joint line.)

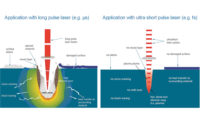

The light passes through the top part and is absorbed by the bottom part. The absorptive part converts the energy to heat, which conducts across the interface to melt both parts and produce a weld. The two halves of the part are clamped together throughout the process.

The waveguide is custom-made for each part, but quick-change tooling can be built to assemble families of parts. “We have customers who change tools daily,” McNair points out.

Illuminating the entire bond line simultaneously reduces overall cycle time, enabling the technology to be considered for high-volume assembly of disposable medical devices. Depending on the application, cycle times range from 0.5 to 5 seconds. “We’ve done applications in as little as 6 to 8 milliseconds per part,” says McNair.

The process can weld a variety of elastomers and thermoplastics, including polypropylene, polyether ether ketone, and high-density polyethylene. “The latter welds very well with a laser, but can be difficult to weld with ultrasonics,” adds McNair.

The top part can be any color, as long as it’s transmissive to near-infrared light. Similarly, the bottom part can be any color, as long it absorbs light. Plastics containing significant levels of glass filler can be problematic, since the fibers can scatter or refract the light.

The process can weld small parts and large parts, flat parts and contoured parts, thin parts and thick ones, and similar and dissimilar materials. “We can weld parts that are only millimeters across, like cannulas, and we can weld large parts, like automotive taillights,” says McNair. “We can also weld membranes and films.”

The process is “quite expensive,” concedes McNair, but for some applications, there are no other alternatives. For example, because it does not depend on mechanical energy to generate heat, laser welding is ideal for welding assemblies that contain sensitive electronics.