Sisters share an emotional bond. Sister companies, however, share a financial and technological bond, which is great news for the Seiko Group and Seiko EPSON. Both companies are able to access each other’s resources and expertise as needed.

Seiko Instruments has been manufacturing watches since 1913. For the first 70 years or so, rows upon rows of assemblers in Japan precisely placed each tiny part into the watch’s frame by hand. However, company management wanted to increase production and improve quality by using high-precision robots for some assembly processes.

So in the early 1980s, Seiko EPSON decided to have its factory automation group use its expertise in high-precision small-parts assembly to develop a robot to automate some of the watch-assembly process. The group developed a small SCARA robot in 1983 that accurately picked and placed several small parts into the watch frame, which was then conveyed to assemblers for further manual work. Production and precision increased significantly, according to Rick Brookshire, senior manager of product development and engineering for EPSON Robotics.

“Today, the mini G1 and small G3 SCARA robots are used to assemble Seiko watches,” explains Brookshire. “But, like the original robots, these models are accurate enough to pick-and-place tiny parts without the use of vision. Seiko EPSON also uses these and other SCARA robots to assemble its consumer products, such as mobile and point-of-sale printers, ink-jet printer cartridges and print heads.”

Since the SCARA robot was introduced in the late 1970s, its accuracy, speed and smooth motion have made it a favorite of manufacturers for a wide range of applications. Better control, simpler programming and greater durability have further increased the robot’s popularity.

Four-Axis Friend

When it comes to robots, one type does not fit all applications. Flexible six-axis robots are good at reaching in and around objects. Delta robots are best suited for high-speed pick-and-place applications with relatively light loads. And, Cartesian-style robots are designed to make precise X-Y-Z movements such as straight line insertions.

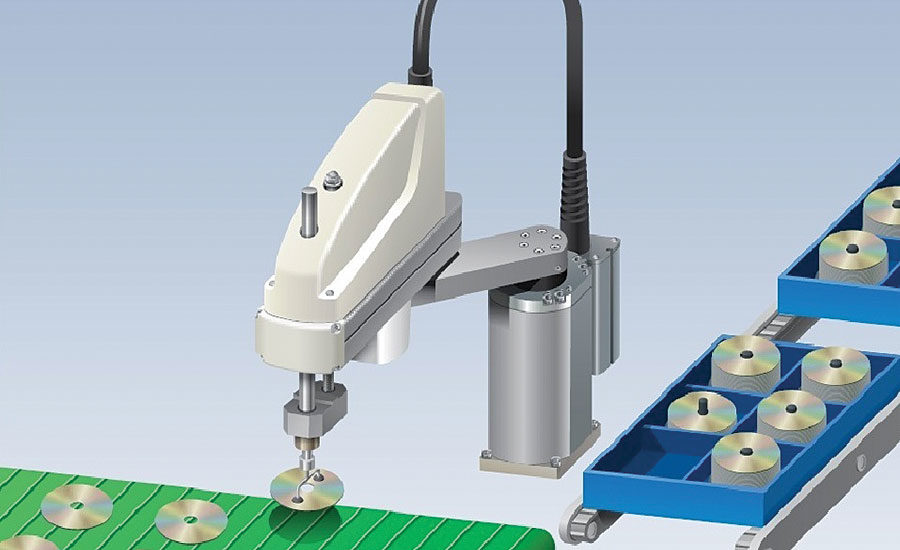

Standard four-axis SCARA robots, in contrast, can effectively dispense adhesives, tend machines, install fasteners, load and unload parts, and perform finished product inspection. The robot’s first two axes are radial joints in the horizontal plane that allow the arm to swivel about its base and fold in on itself like a folding screen. The third, or Z, axis produces vertical motion, while the fourth axis produces rotational motion around the Z axis.

“The speed, repeatability and capacity of SCARA robots have improved significantly this century,” notes Peter Cavallo, manager of robotic sales and planning for DENSO Robotics. “Connectivity has improved as well, with robots now being able to easily communicate with machines via [National Instruments’] LabVIEW graphical programming language on a PLC or PC.”

The SCARA robot has a cylindrical work envelope and performs best when processing workpieces that are oriented in the same plane. When flat parts are presented on a conveyor, for example, the robot uses only one axis to lift a part, or parts, straight up and away from the work surface. It then places the part back down in a straight vertical motion without tilting it.

In recent years, several suppliers have begun offering three-axis SCARAs. These robots eliminate the rotational axis to provide a larger allowable inertial load moment.

“Some suppliers in Asia even make two-axis SCARAs,” says Brookshire. “These are perfect for simple side-to-side and in-and-out-arm-movement processes, such as loading or unloading parts or installing a fastener.”

Manufacturers especially like that the SCARA robot’s single-pedestal mount has a small footprint and saves valuable floor space. It can be mounted over a stationary table and used in the same way as a benchtop robot. A SCARA robot can also be inverse mounted and equipped with a topside tool. This tool goes up and down to easily lift and transfer a part between multiple work locations after each assembly process.

Vacuum end-effectors are often used with SCARA robots, although some suppliers offer specialty grippers that enable the robot to lift parts of different sizes. Increasingly, manufacturers are mounting a vision system to the robot arm. This setup enables the SCARA to scan randomly placed parts on a moving conveyor and identify those in the correct orientation or those with defects.

Kinda Little

SCARAs are usually categorized by overall arm reach of the first two axes. Small models reach up to 350 millimeters, and their maximum payload ranges from 0.5 to 3 kilograms.

Electronics, semiconductor, medical device and automotive parts manufacturers frequently use lightweight IXP robots from IAI America Inc. James Chow, senior technical application support specialist at IAI, says the robots feature a stepper (or pulse) motor rather than a servomotor—making them a lower-cost alternative for low- to moderate- production applications.

Four models are available, all of which have a rated payload of 1 kilogram and a maximum payload of 3 kilograms. These models have arm lengths of 180 or 250 millimeters, can be equipped with a dedicated gripper for cost-effective part transferring and come in clean room versions with specialty dust covers and bellows.

Another series that’s popular with medical device manufacturers is the TS-20 from Staubli Corp. This tabletop robot has a 220-millimeter reach, a payload capacity of 1 kilogram and a work envelope of 8 by 5.5 inches.

According to Sebastian Schmitt, robotics division manager for North America at Staubli, several medical device and electronics manufacturers mount a tiny vision system to the robot arm to ensure quick (120 parts per minute) and accurate part sorting. For clean room applications, a bellows and angled plate are used to protect against dust and liquids.

EPSON’s G1 and G3 SCARAs come in three- and four-axis versions. The four-model G1 series has a payload capacity from 0.5 to 1 kilogram and arm lengths from 175 to 225 millimeters. Payload is higher (1 to 3 kilograms) and arm length greater (250 to 350 millimeters) for the three models in the G3 series. Tabletop and multiposition mounting is possible with all the robots. Phil Baratti, an applications engineer and technical support manager at EPSON, says the three-axis models are often used for fastening and linear dispensing applications.

A nontraditional compact SCARA is the DexTAR double-parallel robot made by Mecademic. All four arm links have the same length, enabling the robot to use all of the lens-shaped workspace (with a 242-millimeter diameter). Although developed for education and training purposes, the robot is built to industrial standards. It is driven by two servomotors and one stepper motor linear actuator, and equipped with high-resolution encoders.

Middle Machines

Midsized SCARAs have a horizontal reach of 400 to 700 millimeters, and a payload capacity of 3 to 10 kilograms. Robots in this class include DENSO’s HS-G4545 and 4555, with arm reaches of 450 and 550 millimeters, respectively. They have a maximum payload of 5 kilograms, a position repeatability of ±0.02 millimeter and a basic cycle time (with 2-kilogram payload) of 0.35 second.

The robots are operated by the compact RC8 controller, which features an easy-to-use graphical interface and communicates with more than 100 types of devices, including vision. Both models come in mist- and dust-proof (IP65) versions, as well as ISO 4 (Class 10) clean room versions. The robots can be mounted to a ceiling for increased versatility.

Earlier this year, ABB Robotics introduced its three-model IRB 910SC series for various assembly, tray kitting, material-handling, laboratory automation and prescription-drug-dispensing applications. The tabletop robots have a maximum payload of 6 kilograms and arm reaches of 450, 550 and 650 millimeters.

An easily programmable IRC5 controller ensures repeatability, short cycle times and proper synchronization with external devices. All three models are IP54-rated to protect against dust and liquids. A clean room ISO 5 option is under development.

“For a long time, automotive Tier 1s and OEMs have been heavy users of midsized SCARAs, as well as other robots,” says Chow. “As a result, they need flexible robot controllers that are easy to program and offer wide functionality.”

To meet this challenge, IAI developed the XSEL-RXD/SXD series of controllers. Because it controls up to eight axes, a manufacturer can use the controller to simultaneously control two four-axis SCARA robots, like the IX-NNN-5020H or 5030H, or the IX-NNN-1505H and a four-axis Cartesian robot. The programmable controller can be configured so a vision system detects parts on a conveyor and triggers the robot to handle them synchronously with conveyor movement.

Also, an operator can enter conditions, such as transfer mass, and specify the optimum acceleration for those conditions (e.g., fast acceleration with a light load or slow with a heavy load) to minimize cycle time in every application. The 5020H and 5030H robots have a 500-millimeter arm length, a 10-kilogram maximum payload and 0.28-second standard cycle time.

EPSON’s LS3 and LS6 robots have arm lengths of 400 and 500 to 700 millimeters, and payload capacities of 3 and 6 kilograms, respectively (with ±0.01 millimeter repeatability). Both models come in ISO 4 clean room versions and use the RC90 controller.

The controller’s RC+ 7.0 simulator software enables automation engineers to quickly design, build and debug virtual robot workcells. This software shows robot orientation and motion in a 3D display from various viewpoints. Before estimating robot cycle times, the software considers speed and acceleration-deceleration settings and determines whether the robot (including end of arm tooling) interferes with itself.

Full Extension

Large SCARAs are designed to move heavier payloads (7 to 20 kilograms) a further distance (750 to 1,000 millimeters). EPSON’s G10 and G20 robots, for instance, move 10- and 20-kilogram payloads up to 850 and 1,000 millimeters, respectively.

Brookshire says both series are operated by the RC700A controller, which is capable of controlling up to 24 axes or four robots in a multi-robot workcell. The controller’s open architecture design lets end-users add third-party software as needed. For added versatility, the robots can be floor-, wall- or ceiling-mounted, and come in clean room, washdown, dust-proof and static-safe versions.

DENSO’s HM-G series features two robots (4085 G and 40A0 G) that also have arm lengths of 850 and 1,000 millimeters and payload capacities of 10 and 20 kilograms. The 40A0 comes in basic, basic UL-listed and floor-mount models, whereas the 4085 G also comes in overhead-mounted, mist- and dust-proof versions. Cavallo says several Asian manufacturers use these robots for servo-press and nut-driving tasks.

The Staubli TS-80 is designed to move 8-kilogram payloads up to 800 millimeters. But, what’s most impressive about this robot, according to Schmitt, is it features the same motor (and offers the same speed and inertial load moment) as the much-smaller TS-20. The robot comes with a 200- or 400-millimeter stroke in floor- and wall-mount versions.

Several years ago, end-of-line-packaging specialist SVZ Maschinenbau GmbH integrated six TS-80s into a custom system for a well-known German food manufacturer. Equipped with vacuum grippers developed by SVZ engineers, the robots pick up and move empty plastic containers that have different color packaging on them.

SVZ receives cartons filled with containers having only one color packaging. The robots’ job is to move containers from each carton and place them into another carton to create a mixed assortment of containers.