General Electric Co. is the world’s largest builder of diesel-electric locomotives. Its products are used by numerous railroads to haul freight and passengers. Thousands of GE machines are in operation every day throughout the world. The locomotives tackle everything from mile-long ore trains in the Australian outback to overcrowded passenger trains in India.

But, it wasn’t always that way. In fact, up until just a few decades ago, GE was considered to be a niche player in the railway industry. Although the company built a diverse array of locomotives in small batches, it was primarily a supplier of traction motors, generators, controls and electrical components.

General Electric has a long, proud history of building innovative transportation products that run on rails. During the past 125 years, the company has made everything from 2-ton electric mine locomotives to 8,500-hp gas turbines. That proud heritage dates all the way back to the early days of the company.

A decade before he helped form GE, Thomas Edison experimented with an electric-powered train at his laboratory in Menlo Park, NJ. The small locomotive pulled two cars along a 1,400-foot-long test track at speeds up to 40 mph.

Edison’s crude machine was powered by a dynamo converted from an electric lighting application. A belt drive connected the motor to the wheels. Electric power was supplied through the rails by a central generator.

In 1882, Edison also carried out experiments with a pair of larger locomotives on a 3-mile track. Despite success, the prototypes failed to catch the attention of railroad executives, who were committed to good-old steam power.

According to Edison, electric locomotives offered numerous advantages, including “no grinding, no jerking, no puffing, no pulling, no straining, no distant slumbers—just a keen sense of moving swiftly, of being propelled by power vastly in excess of requirements. You ride with ease—you are at ease—it is the very last word in transportation.”

An electrical engineer named Frank Sprague (a former protege and assistant to Edison) took that vision and turned it into a reality. His first breakthrough was a constant-speed, non-sparking motor with fixed brushes. Sprague also developed a multiple-unit control system that allowed one engineer to operate a string of passenger cars as a unit.

In the mid-1880s, Sprague invented a system for distributing electricity to streetcars from overhead wires. Trolleys soon began to replace cable cars and horse cars, sparking a revolution in urban transportation.

Along the way, Sprague created the world’s first successful electric street railway system in Richmond, VA. Within two years of its 1888 opening, more than 100 railways using Sprague’s equipment were built or under contract in cities throughout Europe and North America.

The Sprague Electric Railway & Motor Co. was eventually consolidated into the Edison General Electric Co. (GE’s predecessor) in 1889.

During the first half of the 20th century, the pros and cons of railroad electrification were widely debated within a conservative industry where steam ruled supreme.

Proponents argued that electric-powered trains were cleaner, quieter and more efficient to operate. Electric motors provided greater starting power than steam power. And, electrified operations could lower labor costs and increase speed because there was no need to stop for coal, oil and water.

Skeptics balked at the expense of building generating plants and maintaining a spider web-like network of overhead catenary wires. They also raised safety concerns about the hazards posed by high-voltage lines.

Nevertheless, by the outbreak of World War II, the United States had more than 6,000 track-miles operating under electric power, far more than any other nation and more than 20 percent of the world’s total.

In almost every instance, electrification was beneficial to the bottom line. Running times were reduced and tonnage capacities were increased. Fuel and maintenance costs were lowered, and the service lives of electric locomotives proved to be twice as long as those of steam locomotives.

General Electric played a key role in that success. In addition to supplying transformers, turbines and other types of power generation equipment, the company built hundreds of electric locomotives.

Major customers included the Great Northern, Milwaukee Road, New Haven, New York Central and Pennsylvania railroads. General Electric also exported locomotives to customers in Brazil, Mexico and other parts of the world.

After World War II, diesel power dethroned steam and all-electric rail technology. However, GE was also instrumental in the transition to the diesel-electric machines that are widely used today.

“It was GE, more than any other manufacturer, which pioneered the technology with which the diesel-electric was to successfully challenge steam,” claims William Middleton, a railroad historian and author.

Trolley Time

Within a few years after it was formed in 1892, GE became a leading supplier of alternators, controllers, generators, motors, switches and other electrical equipment used on trolley cars, which were transforming cities and towns throughout the United States. The 600-volt DC equipment quickly gained a reputation for durability, reliability and performance on vehicles that were continually starting and stopping while operating under heavy loads.

By 1895, GE was mass-producing more than 8,800 electric motors and more than 90,000 hp of street railway generators. In the company’s 1896 annual report, Edwin Rice, vice president of manufacturing and engineering (and president of GE from 1913 to 1922), claimed that “costs have continued to decrease, particularly in railway apparatus, which has been made in large quantities.”

Most of the products were assembled at GE plants in Lynn, MA, and Schenectady, NY. Production of generators and motors alone increased 35 percent between 1894 and 1895. “This is partly due to the larger size of the average generator and motor constructed, and partly to the growth of the business,” explained Rice.

A full-page ad in the October 1895 issue of the Street Railway Journal proclaimed that “five times as many GE 800 motors are now operating street cars than motors of any other make.” The ad also claimed that “the K2 series parallel controller is the standard railway controller of the world.”

Orders for GE equipment increased 33 percent from 1896 to 1897. And, the company’s 1898 annual report claimed that “the average size of the street railway motor has increased to 34.7 hp, while the average railway generator increased from 356 to 484 hp.”

In 1896, GE unveiled a new motor that weighed 1,950 pounds. The iron-clad armature alone weighed 750 pounds and was 15 inches in diameter.

General Electric engineers designed the motor to be easy to service. Two bowl-shaped castings were hinged and bolted together to form a watertight frame. An 8.25-inch diameter commutator was assembled with 93 bars of hard-drawn copper. It was assembled with a clamping ring nut rather than bolts.

By the end of the 19th century, GE dominated the global market for street car propulsion. In addition to supplying motors and electrical gear, the company produced the electrical infrastructure, such as power stations and substations, needed to generate and transmit electricity.

To showcase its worldwide dominance, General Electric displayed a papier mache globe at the 1900 world’s fair in Paris that was 25 feet in diameter. It was adorned with flags and small incandescent bulbs that indicated cities that used GE equipment in their transport systems. A miniature trolley car circled the globe every minute.

In addition to becoming a key supplier to the street and interurban railway industry, GE gained a reputation for its line of electric mine locomotives. The low-slung machines hauled hopper cars full or coal, copper, lead, tin and other minerals on underground narrow-gauge rail networks. The powerful locomotives quickly replaced horses, mules and other animals.

General Electric also built 40 electric “mules” for guiding ships through the Panama Canal, which opened in 1914. The 32-foot-long locomotives were equipped with 220-volt motors that had towing capacities of 25,000 pounds. Dual electrical and mechanical controls permitted operation from either end. The rugged machines were in operation for 50 years.

Rapid Transit

Shortly after the company was formed, General Electric was responsible for developing a new form of urban transport. When the 1893 World’s Columbian Exposition in Chicago was being planned, GE proposed an elevated railroad that would loop around the exhibition grounds.

The world’s fair officially honored the 400th anniversary of the arrival of Christopher Columbus to the New World. However, unofficially, it celebrated the power of electricity, which was transforming cities and towns everywhere. The fairgrounds featured more than 120,000 incandescent light bulbs, which was more than were in use in the entire city of Chicago at the time. With the focus on the new technology of electricity, the six-month extravaganza served as a “coming out party” for GE.

The fair featured 65,000 exhibitors and marked the debut of many new wonders, including the Ferris Wheel, moving sidewalks and an all-electric “servantless” kitchen. It also featured early prototypes of dishwashers and fluorescent lightbulbs.

And, tucked away in a corner of one of the huge exhibition halls was a “horseless carriage” created by an unknown mechanical engineer from Germany named Gottlieb Daimler. It was the only gasoline-powered vehicle on display and was so obscure that it wasn’t even listed in the fair’s official catalog. But, it attracted the attention of a handful of visitors, including Henry Ford.

Despite all those wonders, the highlight of the world’s fair was the Columbian Intramural Railway, a four-mile elevated system that served 10 stations within the 628-acre fairgrounds on the South Side of Chicago. A 20-minute tour in the open-sided cars cost 10 cents.

Electric power was supplied to the trains through third rails mounted on wooden blocks between the running rails. Twelve trains were in constant service every day from 8 a.m .to 11 p.m. They traveled at 12 mph between the stations.

“The Intramural Railway was a huge success for the brand new General Electric Co., demonstrating convincingly the suitability of electric traction for the heavy demands of urban elevated railway systems,” says William Middleton, author of Metropolitan Railways. “During the 184 days of the exposition, the railway carried [more than 5 million] passengers.”

The railway was designed and built by GE at its factory in Schenectady, NY (individual cars were built by the Jackson & Sharp Co. in Wilmington, DE). Five oil-fed, direct-current generators varying from 268 to 2,000 hp powered the electrical system.

Four-car trains each carried up to 96 passengers and operated with four 133-hp electric motors supplied by GE. At the time, most urban railways were steam powered, which created excessive amounts of pollution and “smoke nuisance.”

General Electric proclaimed that the Intramural Railway “demonstrates conclusively and beyond per adventure that the steam locomotive can no longer hold supremacy in the problem of heavy and rapid

transportation.”

The success of the system opened up new markets to GE and led to rapid transit projects in Chicago, New York and other large cities.

“The General Electric Co. was the first electrical manufacturing company to recognize that the time had come when electricity might be applied to a new field,” proclaimed an October 1895 GE letter to the editor of Street Railway Journal. “The Intramural Railway was constructed and equipped throughout by this company and its success marked the beginning of a new era in city travel.”

At the Chicago world’s fair, GE also exhibited a four-wheel, 30-ton electric locomotive that featured two gearless motors and could run 30 mph. The armatures were wound on hollow shafts through which the axles passed.

Power was supplied at 500 VDC via an overhead trolley wire system. General Electric claimed that it was “the first practically operative high-speed electric locomotive in the world adapted to the requirements of the steam railroad.”

Steam Rival

As the 19th century drew to a close, steam reigned supreme on the world’s railroads. But, growing public outcry over air pollution and smoke abatement mandates forced rail executives to start looking for solutions in large cities.

In 1895, GE entered a new era when it rolled out the largest electric locomotive in the world. The 96-ton machine was ordered by the Baltimore & Ohio (B&O) railroad for use within a new three-mile-long tunnel in Baltimore. The company decided against using steam power to avoid a new city ordinance against severe smoke pollution.

“The electrification contract was an audacious one for both firms,” claims Middleton, author of When the Steam Railroads Electrified. “The railroad risked the success of an $8 million project on an unproven form of motive power. GE, which contracted to provide the electrical installation and locomotives that could handle 500 ton passengers trains at 35 mph or 1,200-ton freight trains at 15 mph up the tunnel’s 0.8 percent grade, risked its reputation in the electric traction field.”

“Despite the growing number of lightweight electric street railways and a few branchline experiments, up until then no railway in the world had attempted to electrify a full-scale mainline operation,” adds Brian Solomon, author of GE Locomotives.

General Electric built three steeple-cab locomotives in Schenectady. The eight-wheeled machines operated via a fixed overhead electrical distribution system. Electricity was supplied by four 500-kilowatt GE generators housed in a nearby power plant.

“Each locomotive weighed about 192,000 pounds, making them much heavier than the typical steam locomotives of the period,” explains Solomon. “Propulsion was provided by four gearless, 360 hp direct-current electric motors.

“Motor armatures engaged hollow quills that surrounded the driving axles, and the quills connected to 62-inch spoked driving wheels using rubber blocks,” adds Solomon. “The blocks provided a flexible connection that cushioned shocks to the motors.”

“The flexible connection between the quill and the driving wheels, normally a coil spring and cup arrangement, reduced the stresses of starting and acceleration on motors and wheels,” adds Middleton.

In 1909, the B&O railroad purchased additional electric locomotives from GE that featured a box-cab design. They operated via a ground-level third-rail similar to what’s still used on many subway systems today.

By the time the B&O ordered third-generation locomotives in 1923, the machines had become much bigger and more powerful. For instance, the Class OE-4 locomotives featured four GE 209C traction motors that developed 1,100 hp.

General Electric engineers were strong proponents of direct-current technology, citing its overall simplicity and ease of motor control.

“The disadvantages of low-voltage DC systems were largely overcome by the development of high-voltage systems during the first decade of the 20th century,” says Middleton. “High-voltage DC equipment was developed around 1906 by GE, which aggressively marketed the system as an alternative to the single-phase AC system advocated by the Westinghouse Electric Co.

Around the same time, General Electric also forged a long-term strategic alliance with another company that was based in Schenectady, NY, the American Locomotive Co. (Alco). Westinghouse had a similar agreement with Alco’s arch rival, Baldwin Locomotive Works. Up until the 1930s, Alco controlled 47 percent of the market, followed by Baldwin with 39 percent.

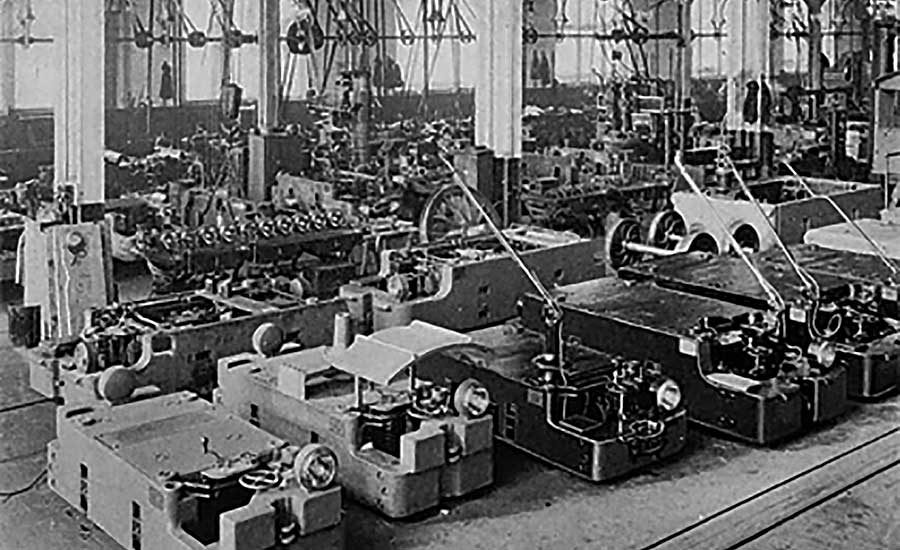

Eventually, GE helped change the way that locomotives were built, evolving from flexible small-batch production methods to mass-production techniques. In the past, “skilled craftsmen created parts and subassemblies to precise specifications, yet manufacturing tolerances were somewhat ‘loose’ and parts often varied by as much as 0.01-inch….In the erecting shop, skilled craftsmen built, rather than assembled, the locomotive piece by piece,” says Albert Churella, author of From Steam to Diesel.

According to Churella, anti-smoke ordinances in major cities drove development of the first diesel-electric locomotives in the early 1900s. At the time, heavy amounts of smoke, soot and cinders caused excessive air pollution and led to numerous accidents.

One of the most infamous incidents occurred in New York City on Jan. 8, 1902. A New York Central express train plowed into the rear of a New Haven commuter train just north of Grand Central Terminal, killing 15 people. The engineer responsible for the accident was unable to recognize signals amidst all the smoke in the terminal’s approach tunnel. In response, the State of New York banned steam locomotives from Manhattan by 1908.

When the New Haven, New York Central and Pennsylvania railroads decided to electrify their main lines into New York City, GE engineers stepped up to the challenge.

In 1904, GE designed and built a prototype locomotive for the New York Central that could haul fast express trains in and out of Manhattan. The double-ended machine featured a center-cab configuration.

In a dramatic series of tests, the 3,000-hp locomotive consistently outperformed a state-of-the-art steam locomotive. That success resulted in an order for a fleet of 46 nearly identical units.

The locomotives departed radically from previous designs. In fact, Asa Batchelder, a GE engineer, obtained four U.S. patents for various features of the machines.

“My invention relates particularly to the construction of electric locomotives, and comprises a novel construction of the frame or body of the truck on which the superstructure of the locomotive is mounted, which renders possible the utilization of the frame as the field-magnet structure for the propelling motors,” reads U.S. Patent No. 808,717.

Batchelder’s S2 class machines were the world’s first mass-produced main-line electric locomotives. The 37-foot-long units weighed 95 tons. They were capable of an acceleration rate of 1 mph per second with trains of up to 800 tons.

“The principal feature of Batchelder’s design was the use of bipolar gearless motors,” says Middleton. “The armatures of the four traction motors were mounted directly on the driving axles, while the field magnets and pole pieces were carried on the locomotive frame. The arrangement eliminated the need for either gearing or the usual motor mountings.”

“Erie Built”

Because of the success of the S2 locomotive, GE’s assembly plants in Lynn, MA, and Schenectady, PA, reached their capacity by 1906.

“Rather than expand at either site, GE decided instead to establish an entirely new plant that would be closer to its growing Midwestern market,” says Middleton, who wrote an extensive article on GE’s history for the September 1999 issue of Trains magazine. “After considering potential sites between Buffalo and Cleveland, the company chose a location at Erie, PA, midway between the two larger cities and ideally located for access to both rail and water transportation.

“By early 1907, GE had acquired some 700 acres and, after a delay due to a business recession, work on the first buildings began in 1910,” adds Middleton. “A year later, the company’s electric traction manufacturing was shifted from GE’s other plants to the Erie Works, which has been the center of GE’s railroad business ever since.”

The term “Erie built” soon became synonymous with high-quality locomotives.

Outside of New York City, most railroad electrification schemes were confined to mountainous terrain, such as the Appalachians, Cascades and northern Rockies. One of the most audacious projects was the Milwaukee Road’s 656-mile-long Pacific Extension.

The railroad embarked on the endeavor because of a 1914 report that praised the merits of electric locomotives. “It found that, in comparison with steam operations, electric locomotives allowed a 9 percent increase in gross ton miles, with 26 percent fewer trains and an overall savings of 36 percent,” says Middleton.

To tame the formidable mountain operating conditions in Idaho, Montana and Washington, GE delivered powerful locomotives equipped with two pairs of 52-inch driving wheels that allowed passengers to ride “as smooth and jerkless as that of a powerful ship on a summer sea.”

Each pair of wheels was driven by a GE Type 253-A traction motor with a one-hour rating of 430 hp and a continuous rating of 375 hp.

“A nose-hung mounting was employed for the motors, with twin gearing to the driving axles,” says Middleton. “The use of both a spring gear drive and a spring nose suspension minimized shock on the motors from the high tractive forces.

“One of the most important features of the locomotives was the capability for regenerative braking on descending grades,” adds Middleton. “The engineer, using the auxiliary handle on the master controllers, could employ the traction motors as generators to return power to the [overhead] wire in the amount required to maintain a desired speed.”

In a 1917 advertisement, GE boasted about its role in the remarkable engineering feat. “High among the bald peaks of the Montana Rockies, 6,000 feet above sea level, high-speed, smokeless passenger trains and record-tonnage freight trains of the Chicago, Milwaukee & St. Paul wind their way up and over the Continental Divide under electric power.

“These trains cross 400 miles of mountain ranges… over the same tracks where a few months before giant steam locomotives had faltered on the upgrades and overheated their brakes to redness while descending.”

“The Milwaukee Road’s new electrics shattered every previous record for power and tractive effort, and the publicity men made the most of it,” explains Middleton. “The first locomotive completed was shipped from GE’s Erie Works in late September 1915 with 40-foot banners on each side that immodestly proclaimed it to be the ‘largest locomotive in the world.’

“At Chicago, the first stop on an exhibition tour that included every major point on the Milwaukee Road all the way to Seattle, an estimated crowd of 10,000 viewed the locomotive during the four hours it was on display near Union Station,” Middleton points out. “The [electrification project] captured the public fancy as had few comparable engineering achievements.

“To an age not yet jaded by the latest advancements of technology, there was something wondrous about trains that preserved dwindling reserves of coal and oil by taking their energy from the ‘white coal’ of rushing mountain streams, made no smoke or cinders, and frugally returned electricity to the wires by the magic of regenerative braking,” notes Middleton.

After delivering the initial order of 42 two-unit box-cab locomotives, General Electric engineers eventually developed machines that grew larger and even more powerful. “The versatile GE locomotives adapted easily to the challenge of increasing train tonnages,” claims Middleton.

By the time the Erie Works built its last batch of electric locomotives for the Milwaukee Road in 1946, the powerful 88-foot-long behemoths required 24 wheels. They were equipped with eight GE 750 motors that boasted a continuous rating of 5,110-hp and operated on a 3,000-volt DC system. The “Little Joe” locomotives produced 75,700 pounds of tractive effort.

The heyday of all-electric locomotives ended after World War II with the advent of reliable, cost-effective diesel machines. However, some railroads, such as the Milwaukee Road and the New York Central, continued to operate GE-built units for decades. For instance, one electric locomotive served on the Milwaukee Road from 1915 to 1974.

“Despite all the enthusiasm, despite all the seemingly unassailable arguments for electrification, despite the many successes, railroad electrification in North America failed to achieve the wide application that was so confidently predicted,” laments Middleton. “For every electrification project that became a reality, there was another that didn’t.”

“Despite the many prospective advantages of electrification, railroads observed the developing technology cautiously,” says Solomon. “The high initial costs of electrification were difficult for railroads to justify, despite the allure of lower operating costs.

“In addition to the great expense of electrical supply equipment and specialized locomotives, electrification required separate shops and specially trained mechanics to maintain the equipment,” adds Solomon. “Other costs included expensive signaling equipment that was shielded from interference with its electrical transmissions. The specialized and somewhat inflexible equipment imposed operational constraints.”

Today, only a few all-electric passenger trains still operate in the United States. Most of them run on Amtrak’s Washington-Philadelphia-New York-Boston Northeast Corridor and on the South Side of Chicago along the Metra Electric District and South Shore Line.

Dawn of the Diesel

As early as 1904, General Electric engineers explored the possibility of using internal combustion engines for railway applications. That’s the year that a gas-electric project group was organized within the railway engineering department in Schenectady.

They experimented with a variety of self-propelled railroad cars equipped with six-cylinder engines, 600-volt generators, 75-hp electric motors and street car controllers. After a series of tests proved successful, GE launched a line of production cars in 1910. The company eventually built 94 gas-electric machines for a variety of railroads before the gas engine department was disbanded in 1919.

“General Electric’s pioneering railcar research and development efforts during the 1910s established the superiority of electric transmission,” says Churella, a history professor at Kennesaw State University. “The next logical step was to create a separate locomotive, and GE took the lead.”

In 1914, a GE engineer named Herman Lemp developed a revolutionary system that controlled electrical and mechanical transmission parts with a single lever and kept them in balance. His solution was widely used in diesel-electric locomotives for more than 50 years.

“Lemp patented improvements to this system in 1919, and then continued further control system development even after GE ended its gas and diesel engine programs,” says Middleton. “By 1922, Lemp had developed a much improved, entirely electrical system through which an engineer could properly control both engine output and generator field excitation from a single control handle.

“The principles established by this improved Lemp control system were a key milestone in the development of the diesel-electric locomotive,” adds Middleton. “It set the stage for the next step in GE’s involvement with this form of motive power.”

In 1920, Lemp also began working on a 300 hp diesel engine for locomotive use. In 1923, GE completed a prototype equipped with a six-cylinder engine manufactured by Ingersoll-Rand. It led to the first significant demonstration of diesel-electric power on U.S. railroads. Between 1925 and 1931, GE and its partners produced 50 box-cab locomotives that were used for switching and industrial applications.

“By the late 1930s, GE was producing a line of standard industrial diesel-electrics ranging from 25 to 80 tons, and powered by such engine suppliers as Caterpillar and Cummins,” says Middleton. “This was to provide a promising market niche. By 1948, GE would be able to claim a total of more than 1,500 of these units at work for industrial customers all over the world.”

After World War II, GE capitalized on increased demand for locomotives that weighed less than 90,000 pounds. It was in response to a 1937 railroad labor agreement that allowed one-man operation of lighter locomotives (heavier machines required both an engineer and a fireman).

General Electric took advantage of advances in diesel engine performance and cutting-edge manufacturing techniques to develop a single-engine machine that weighed much less than comparable alternatives. Switchers became an important part of GE’s locomotive business for many years.

Between 1940 and 1956, GE produced more than 640 two-axle and four-axle locomotives in various sizes, with power ranging from 400 to 660 hp. By the 1970s, it had produced more than 5,000 small locomotives for service in dozens of countries around the world.

“More than 80 percent of the diesel-electric locomotives in this country use GE electric equipment,” proclaimed a magazine ad from the time period. “All available figures show that maintenance on new diesel-electric switchers is from 40 percent to 60 percent lower than on new steam locomotives.”

In the late 1930s, GE engineers began experimenting with steam turbine-electric locomotives that were used by the Union Pacific railroad. They combined established marine and stationary steam turbine systems with electric propulsion technology to create a new type of locomotive.

After World War II, the engineers modified gas turbines from jet aircraft engine designs. By 1957, they succeeded in coupling 8,500 hp turbines to common GE 752 traction motors. The Union Pacific boasted that 12 percent of all its long-distance freight traffic was hauled by a fleet of gas-turbine machines. Despite numerous advantages, however, the novel technology proved to be much less efficient than diesel-electric locomotives.

The 1950s was a transition decade for the railroad industry as steam power quickly succumbed to diesel technology, which offered numerous advantages.

Diesels were easier to operate and required only one operator, which provided greater ease in switching and yard operations. They were quieter, operated in all types of weather, and offered climate-controlled cabs for an improved work environment. Diesels also offered instantaneous start up and stopping ability, and they incurred no costs due to downtime.

In addition, many steam locomotives were custom-made one-offs, which often cost as much as 25 percent more than their diesel equivalents that could be more easily mass-produced. Diesels quickly grew in popularity due to uniformity of construction and less complex, readily available parts.

In 1953, GE pulled the plug on its long-time alliance with Alco and decided to strike out on its own with a new line of products. At the time, 62 percent of all diesel locomotives in service were made by General Motors’ Electro-Motive Division (EMD), followed by Alco at 24 percent. By 1960, Alco’s market share dropped to 13 percent.

“As the problems associated with Alco’s postwar diesel production became increasingly apparent, GE executives worried their own company’s reputation would suffer, and that they would lose a significant market for GE electrical equipment if Alco exited the locomotive business,” says Churella.

Another factor that contributed to the decision was additional space coming available at the company’s Erie factory. GE’s refrigerator assembly line was in the process of moving to the new Appliance Park in Louisville. The first refrigerator was built there in 1954.

By 1960, General Electric had orders for 200 locomotives of various types and sizes, totaling $31 million. That’s the year that GE entered the heavy-duty diesel locomotive market with its popular Universal (U) Series. The first product was the 2,500-hp U25B.

A two-page advertisement in Railway Age magazine announcing the machine proclaimed it to be “the new standard of motive power.” The locomotive featured a short, stubby nose, but it was durable and easy to maintain.

“Seven years ago, the American railroad industry helped General Electric plan a new locomotive concept,” read the ad copy. “The industry asked for a new locomotive…with greater horsepower…on four axles…reliable and economical to operate…and of simple design. Based on these present and future railroad needs, GE engineers developed a new locomotive, combining a new, integrated approach with proven components. The General Electric U25B is that locomotive.”

“GE’s Universal Line had a basic advantage over existing diesel locomotive designs, because it was developed new, as opposed to suffering from the restraints of evolutionary development,” says Solomon. “Working from its strengths, GE set out to build a machine with a much simpler electrical system.

“During the 1940s and 1950s, GE refined its already excellent traction motor designs while consolidating motor production facilities at its Erie, PA, plant,” adds Solomon. “GE also worked through the other elements of locomotive design, carefully choosing an appropriate prime mover and designing an effective air-flow and air-filtering system. Its Universal Line locomotives used far fewer components than competing models and its railroad traction equipment was the most respected in the industry.”

The U-Series would ultimately span 476 units and a total of six different designs ranging between 2,500 and 3,500 hp. The reliable, easy-to-maintain machines put GE on the path to becoming the largest locomotive builder in the world.

“What had transpired during this long incubation period was that GE had completely rewritten the locomotive design handbook,” says J. Parker Lamb, an engineer and author of Evolution of the American Diesel Locomotive. “It had concluded that the most desirable characteristics at that time were simplicity and reliability, and that the second usually followed the first.”

Groundbreaking innovations on the U-Series included a super-efficient air intake filter, a self-draining radiator, and a new wheel-slip detection and control system.

By the mid-1960s, GE had bumped Alco from its No. 2 spot. But, in 1968, GE still only accounted for 22 percent of the market vs. 70 percent for EMD. Between 1968 and 1980, average annual production for EMD was 992 units vs. 281 for GE.

However, after numerous product improvements and innovations, in addition to quality programs and agile manufacturing initiatives, GE finally overtook EMD for the No. 1 spot in 1987 and hasn’t looked back. Between 1981 and 2002, average annual production for GE was 622 units vs. 338 for EMD.

Beginning with its Dash 7 Series of the late 1970s, General Electric solidified its lead in the locomotive production race.

“During the early 1980s, GE reduced its locomotive line from 14 models to nine, and halved its available product options to 277,” says Churella. “The company spent $316 million on improvements to its Erie manufacturing facilities, installing robots and computerized quality control equipment.”

In 1983, a year after IBM launched the desktop computer, GE unveiled its revolutionary Dash 8 Series. The objective was to substantially reduce locomotive failures while producing a 30 percent increase in reliability.

The world’s first computerized diesel locomotive featured a microprocessor for controlling things such as engine performance and wheel slip. Computers enabled diagnostic tools for tracking a locomotive’s performance history and making preventative maintenance easier.

“Microprocessor control was the key to the Dash 8 design,” says Solomon. “Although computers had been around for many years, it wasn’t until the early 1980s that technological advances made possible powerful computers that were both small enough and sufficiently rugged to fit on a locomotive and endure the harsh conditions imposed by a railroad environment.

“The initial Dash 8 models employed three different computers that were situated in the locomotive’s electrical cabinet,” explains Solomon. “Each computer had its own specialized functions and managed specific locomotive systems to achieve optimum performance.”

From 1984 to 1994, GE assembled more than 1,500 copies of the 4,000-hp Dash 8 locomotive. They featured advanced motor technology with reduced operating temperatures and greater moisture resistance.

Engineers also developed a new type of electrical transmission. It used an alternator that was capable of supplying high voltage and high current to motors without the need for transition switching.

In addition, electronic fuel injection offered improved fuel economy with reduced emissions and lower maintenance costs. Engineers used a single air-cooled inverter for each traction motor, which improved performance and reduced downtime.

“Overcoming the need for transition in Dash 8 locomotives allowed GE to wire the locomotives in full parallel, providing superior adhesion characteristics,” says Solomon. “Also, since the complex electrical switchgear required to make the transition was eliminated, the Dash 8 was a simpler machine electrically.”

Modern Marvels

More than two decades ago, General Electric engineers embarked on a 10-year, $400 million project to completely redesign the company’s best-selling rail transportation product. Their impetus was the U.S. Environmental Protection Agency’s strict new emission standards that were released in 1998.

The Evolution Series, which launched in 2005, was the answer to that challenge. The “green” locomotives provide higher reliability and lower life-cycle costs than previous GE models.

“GE engineers looked at every component going into the new design to ensure that it was the best one for the job,” says Sean Graham-White, author of GE Evolution Locomotives. “It meant redesigning and developing new components to best meet requirements.”

General Electric engineers generated 25 new U.S. patents in the process of developing the groundbreaking machine, which the company claims is “the most fuel-efficient, most environmentally friendly diesel locomotive in history.”

The engineers developed a locomotive platform that exceeded the EPA’s 2005 Tier 2 emission standards. Along the way, they created a new 12-cylinder diesel engine called the GEVO that equaled the horsepower generated from an earlier 16-cylinder unit. It features numerous cutting-edge features, such as hybrid air-to-air cooling, consolidated controls and improved braking.

Fewer cylinders minimize the surface-to-volume effects on combustion inefficiencies and pollutant production. The GEVO engine also reduced the number of parts of its 43-year-old FDL predecessor by 50 percent, which increased reliability and simplified assembly.

To mass-produce the Evolution Series, GE adopted lean manufacturing techniques at the 350-acre Erie Works, which consists of more than 10 buildings.

The radiator cab line in Building 12 was the first lean line. “Production there went from seven days a week to meet pre-lean production goals to five days a week with lean,” notes Graham-White. “At a cost of $2.5 million, lean made a huge difference on the line.”

Final assembly takes place in Building 10. The 307,000-square-foot “erecting shop” is the heart-and-soul of the Erie Works.

Station 3, where five major subassemblies, such as the operator’s cab, are installed, was converted to lean manufacturing in 2006.

“Before lean, locomotives were moved to one of six workstations and remained at that position until all of the assembly had been completed,” explains Graham-White. “Workers would move back and forth between each of the six stations to complete various tasks. That’s transitioned to a more progressive line under lean. Now, locomotives ride air bearings between five workstations.

“With lean, processes are more efficient and the work can be performed by fewer people,” says Graham-White. “Before lean, there were 124 people in three shifts at Station 3, but now there are 88 producing the same volume.”

General Electric’s latest offering in the Evolution Series is the ET44AC, which features a diesel engine designed to comply with the EPA’s stringent Tier V emission regulations. The turbocharged four-cycle, 12-cylinder GEVO-12 produces the same 4,400 hp as its 16-cylinder FDL-series predecessor, but with 5 percent less fuel and more than 40 percent fewer emissions.

The turbocharged engine provides efficiency, fewer emissions and extended overhaul intervals. It also uses enhanced cooling and high-strength materials to improve reliability and allow for future increases in power and efficiency.

The diesel engines are assembled at GE’s 46-year-old factory in Grove City, PA. In the three years leading up to GEVO production, $31 million was spent to upgrade and enhance manufacturing capabilities at the plant. General Electric recently spent more than $70 million to expand the facility, including a separate building dedicated to remanufacturing services.

Evolution Series locomotives are still assembled at the 106-year-old Erie Works. However, GE is in the process of shifting more production to a 1-million-square-foot plant in Fort Worth, TX, that opened in 2013. Last year, the state-of-the-art facility produced its 1,000th locomotive.

General Electric is also in the process of building a new locomotive factory in Bihar, India. It’s part of a $200 million effort to develop and supply Indian Railways with 1,000 diesel locomotives.

Today, GE locomotives are embedded with advanced sensor technology and Predix software that allows them to stay connected to the Industrial Internet. The goal is to produce “rolling data centers that are continuously communicating with a connected ecosystem.”

Working with Intel Corp., GE Transportation recently unveiled a “superbrain” platform solution for locomotives that transforms them into mobile data headquarters. It improves operations, fuel efficiency, horsepower and emissions, and enhances a locomotive’s tractive effort.

“GoLINC interfaces with both onboard and off-board GE and third-party systems to create a powerful Predix-edge-enabled device,” says Jamie Miller, president and CEO of GE Transportation. “The new offering will allow for better data management and video analytics on the locomotive, and enables the creation and deployment of future technologies into the GoLINC platform.”

General Electric also operates a Global Performance Optimization Center in Erie, PA, that’s dedicated to improving customers’ operations 24 hours a day. The 10-year-old facility monitors messages from more than 17,000 locomotives for 53 customers in 23 countries.

“They have created a communication path to send data off a moving asset and hold numerous patents for advanced diagnostics and algorithms,” says Miller. “The system automatically analyzes these messages on over 2 terabytes of operational history. The outputs are reviewed and constantly improved upon by a team of 24 technical specialists and domain experts.”

The engineers process more than 2 million messages per day and provide real-time alerts to customers. Typical messages include “low on fuel,” “train approaching destination in 15 minutes,” “engine derating due to weak turbo boost” and “quick maintenance needed at next fueling.”