Among the most innovative features on a new car is the keyless antenna, which emits a radio frequency signal to identify the owner’s key and open the car. Sumida Components & Modules GmbH makes coils for these antennas, as well as for anti-lock braking systems, actuators, transmissions, suspensions and engine immobilizers. The company also makes rotors for position sensors, components for infotainment systems and xenon modules.

Sumida workers assemble these products at factories throughout Asia and Europe, and in Mexico. The company’s main European plant is in

Obernzell, Germany, where assemblers use DELO Dualbond UV-cure adhesive to bond litz wire within high-frequency power circuits and other electronic components.

Anatoli Esch, technology specialist at Sumida, says the one-part adhesive has performed well the past several years. However, the automated equipment and valves the company initially used often dripped and dispensed more material than was needed, resulting in waste and production setbacks.

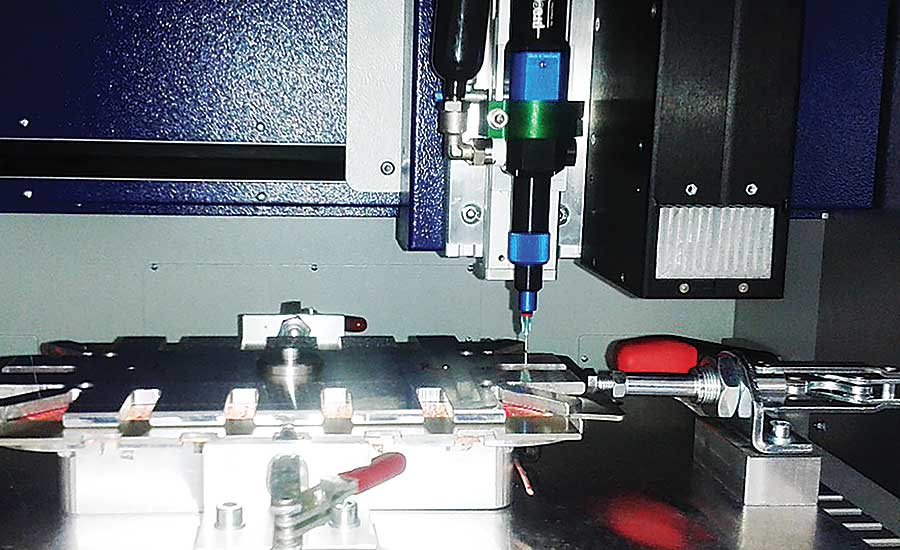

Management began looking for a dispensing system that not only prevented both problems, but was cost-effective and ensured precise dosing for every application. Eventually, Sumida installed preeflow eco-PEN, a positive-displacement dispensing system made by ViscoTec Pumpen u. Dosiertechnik GmbH.

This system features an internal rotor that accurately doses and dispenses a wide range of material viscosities with no stress on the material. It also easily integrates with UV-cure modules and lets workers quickly change application parameters on the system’s EC200 controller.

Four models (300, 450, 600, 700) of the eco-PEN are available, all of which offer adjustable-rate dispensing. The 300 series dispenses 0.12 to 1.48 milliliters per minute, in dosages as small as 0.001 milliliter. Capabilities of the other series are: 0.5 to 6 milliliters and 0.004 milliliter for the 450, 1.4 to 16 milliliters and 0.015 milliliter for the 600, and 5.3 to 60 milliliters and 0.006 milliliter for the 700.

With the EC200, an operator can gain full control of an automated process by simply connecting external signals to a PLC. The controller also quickly recalls a wide variety of stored dosing programs, monitors adhesive fill level and motor current, and constantly displays supply pressure in bar or psi.

To complement the preeflow eco-PEN, ViscoTec has introduced the eco-DUO system for two-part formulations, and the eco-SPRAY system for low- to high-viscosity fluids. All three systems are used by manufacturers in many industries, including optics, photonics, medical technology, biochemistry, LED, photovoltaics and surface mount technology.

For more information on positive-displacement dispensing systems, call 770-422-4281 or visit www.viscotec-america.com.