We in the USA always talk about how everyone speaks English. This may be true of top managers around the world, but in general, plant engineers are most comfortable with their own language.

When you speak to others in their own language, you gain respect, but at the first difficulty, people tend to revert to their native tongue. Some words, however, defy translation. In China, for instance, the term “fuel injector” has no precise equivalent, and loose translation can lead to confusion between people of different nationalities.

Sometimes in leak testing, it seems like a translator would be helpful even when we all speak the same language! For instance, no matter where I go, it seems there is much confusion about mass flow and pressure decay.

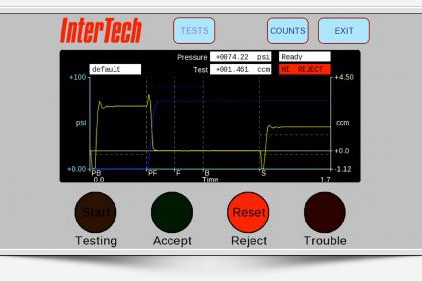

With all the language considerations in today’s global marketplace, the best thing we can do to help our customers is to equip controls with different language options. Interactive controls like touch screens help even more.

I predict technology will trend toward devices that utilize the native language of operators and engineers through traditional and other sensory inputs such as touch screens. This is a top consideration at InterTech. How will your business overcome language barriers?

Jacques Hoffmann is president of InterTech Development Co., which designs and builds equipment for leak testing, functional testing and test-centric assembly. He can be reached at 847-679-3377.

Editor’s note: “Hoffmann on Testing” is part of a series of guest spots by industry experts that will appear regularly on ASSEMBLY’s blog page. Check back frequently to read more commentaries from Jacques, as well as contributions on automated assembly systems, machine vision, robotics and ergonomics.

Recent Comments

Helpful for Trainees

Cable Assembly Manufacturers

Huawei for manufacturing?

should have a scanner and then 3D print the repair

IPC-A-610 and IPC-j-std-001