This trend puts increasing pressure on design and manufacturing engineers, because automation gets more difficult as product sizes and assembly tolerances shrink. To make matters worse, engineers must deploy capable assembly systems for these products ever more rapidly.

Many manufacturers can't change their assembly processes fast enough to keep up with changing marketplace demands. It may take four months or more to design, build and debug an automated assembly line. The product, however, is likely to be obsolete within 6 months.

Today's approach to flexible multirobot assembly lines tends to be "robot(check)centric." That is, everything revolves around the robots. Ancillary equipment, such as conveyors, parts feeders, tooling, vision systems and sensing devices are added to the mix in a more or less ad hoc fashion. The resulting systems are often very complicated and take a long time to deploy.

Numerous factors, such as incompatible communication protocols, large numbers of cables, fixed conveyances, custom parts feeders and custom end(check)of(check)arm tooling, challenge manufacturing engineers. If the product is successful in the marketplace, customers will soon line up to buy new product variants. This, in turn, demands additional flexibility in the assembly system.

The solution to all these problems is an assembly system that is flexible--to deal with variability in the assembly process--and agile, so it can respond rapidly to changing market pressures.

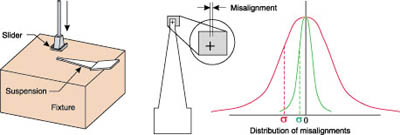

Most precision assembly applications today rely on SCARA robots that have a repeatability of approximately 50 microns at best. Vision can increase precision, but placement accuracy is still limited by the motion resolution of the robot, which may not be much better than 50 microns. As a result, micron-level assembly operations usually require the addition of expensive precision motion stages, relegating the robot to mere load and unload tasks.

There are fundamental limitations to the precision of the ubiquitous SCARA robot design. The problem lies with the shoulder and elbow joints, where actuators and encoders are located far from the end effector. One tick of the shoulder encoder, for example, results in a fairly large displacement of the end effector. Intervening joint friction and flexibility, and arm dynamic effects, reduce precision even more. Additionally, the SCARA's precision depends greatly on the arm configuration.

A Solution

Rapidly deployable precision assembly systems may provide a solution to this dilemma. Recent research at Carnegie Mellon University has led to the development of a highly agile system.The Microdynamic Systems Laboratory operates within the Robotics Institute of the School of Computer Science. For the last 5 years, a team of researchers has been exploring the limits of robotics in terms of speed, precision, dexterity and miniaturization. We have developed new sensing, actuation and control technologies for agile robotic systems that can be applied to a variety of real-world manufacturing applications.

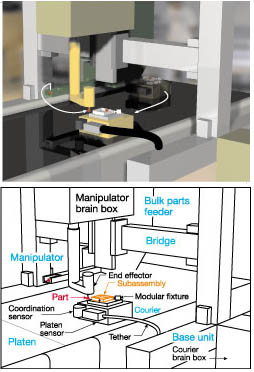

Specifically, we have created tabletop-sized factories. These minifactories consist of modular elements such as high-precision platens, bridges for mounting modular robotic elements, precision 2-degree-of-freedom (DOF) manipulators, 2-DOF couriers and parts feeders.

Rather than trying to improve on the precision of 4-DOF SCARA robots, we have chosen to separate the SCARA's functionality into a pair of 2-DOF robots that act together to duplicate the functionality of the SCARA design. The first of these 2-DOF robot classes are manipulators, which perform vertical motion and rotation, like the last two axes of the SCARA.

These manipulators are mounted at fixed locations within the minifactory and feature their own powerful computers. The couriers, which perform translational motion in the plane, are responsible for moving products through the minifactory. They interact as needed with manipulators to perform 4-DOF assembly operations.

Manipulators are clamped to structural bridges spanning the minifactory workspace, and are connected to locally mounted parts feeders. Each manipulator deals with a single part type. Manipulators have interchangeable end effectors, some of which can be equipped with machine vision and force sensing devices.

The manipulators have direct-drive rotation actuators with high-resolution encoders. Vertical axes employ a precision high-pitch ballscrew mechanism. Gravity loads are cancelled by a regulated vacuum system. Angular repeatability is approximately 0.00008 degree. Vertical repeatability is about 5 microns.

The couriers are based on closed-loop planar motors that travel freely on air bearings over a "factory floor" consisting of precision platen tiles connected together end to end. Rectangular tiles measure 0.6 by 1.2 meters and are field joinable. Rectangular and square platen tiles can be joined together to form various factory topologies, which can include T- and L-junctions.

Couriers can cross the boundary between tiles, and have a range limited only by their tethers supplying air, power and signals. The ensemble of platen tiles eliminates the need for transport mechanisms such as conveyor belts. Unlike commercial motors based on an open-loop stepping principle, the couriers incorporate an AC-magnetic sensor that measures X, Y and O position and orientation with respect to the platen. The sensed information is used in a closed-loop control system, providing higher accelerations and velocities, greatly reduced settling times, and reduction of mechanical disturbances.

Couriers can move more than 1.5 meters per second and can position themselves with a resolution of 0.2 micron. Each courier has an actuated modular fixture or vice for holding a subassembly. It also has an optical coordination sensor. Couriers use this sensor to find overhead light-emitting diodes mounted on manipulators and other devices in the minifactory. A courier and manipulator can automatically calibrate each other to within 0.15 micron, even in the presence of interference, such as overhead fluorescent lighting.

Once calibrated, a manipulator and courier can proceed cooperatively with 4-DOF operations. A single courier can visit many manipulators or other processing devices, such as adhesive dispensers, screwdrivers, welders or lasers. When the tether runs out, the subassembly must be transferred to another courier to continue its journey through the minifactory while the first courier returns to get a new subassembly.

The minifactory system needs more than twice as many robots as the conventional SCARA approach. However, each robot, having only two DOFs, is only about half as complicated as a SCARA. In addition, the combination of manipulator and courier delivers about 100 times the precision of a SCARA in about a tenth of the space for the same size product.

Unlike a SCARA robot, which must use all of its DOFs while picking and placing a part, a manipulator can pick a part from a feeder at the same time that a courier is moving a subassembly into position. Micron-level assembly operations can be done anywhere in the minifactory without the need for special precision stages. These advantages have substantial merit for future products relying on precision assembly.

Future Applications

The goal of the minifactory is to minimize the time and effort needed to go from a product design to an operating assembly system. Several important features have been built in to the system from the outset. For instance, each active device, such as the manipulator, courier and glue dispenser, is a self-contained module with its own computer. It connects to a modular minifactory base unit with a single modular cable supplying power, air, vacuum and network services. Each module has a strictly defined mechanical, electrical and software interface.In the near future, many different vendors will beable to participate in minifactory systems by following a basic set of specifications. Within a given module, a vendor will have complete freedom in its operation, as well as the ability to hide proprietary software. In physical terms, a minifactory with 20 or 30 active devices can be set up with only a few simple hand tools in less than a day.

There is much more to the minifactory than physical modularity. Indeed, each module contains its own complete geometric solid model and functional description, and has the ability to represent itself to the rest of the minifactory system. Because of this characteristic, we refer to each module as a robotic agent. Each agent has a physical and virtual aspect. With these attributes, a complete minifactory may one day be designed over the Internet. It will be possible to create a detailed and accurate virtual minifactory that can be programmed to assemble a virtual product.

The minifactory designer will be able to mix and match agents from multiple vendors while designing and optimizing the assembly system layout. After this virtual minifactory performs as desired, the physical agents can be ordered and plugged together to create an operating system. Design, programming, debugging and monitoring of the virtual and real minifactories is accomplished through a single, centralized software interface tool. With these technologies and methods, it will be possible to reduce deployment times for future precision assembly systems from months to weeks.

The research team at Carnegie Mellon has designed, built and operated a number of prototype minifactory agents and related infrastructure. We have successfully performed cooperative vision-guided assembly of tiny microphone parts and cooperative force-guided peg-in-hole insertion tasks.