Home » harness assembly

Articles Tagged with ''harness assembly''

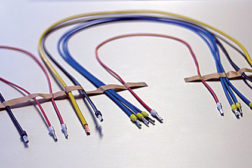

Cost Reduction in Wire Harness Assembly

Experience, foresight and a reliable enterprise resource planning (ERP) system are the keys to cutting expenses throughout the wire harness assembly process.

June 15, 2021

Case Studies in Wire Harness Assembly

These success stories highlight the need to use the latest processing equipment, workbenches and testing systems on the shop floor.

October 11, 2018

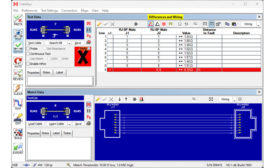

Harness Assembly Goes Digital

A new, interactive harness assembly board promises to prevent errors and improve productivity.

April 16, 2018

Robotic System Assembles Cords

A unique multistation automated assembly system produces six different cord sets.

April 13, 2018

Sealing Crimped Contacts Avoids Corrosion

Miele uses a dual-curing adhesive to seal electrical contacts in its washing machine motors.

January 16, 2018

Quality Is Top Priority When Assembling Wire Harnesses for Medical Devices

Successful contract manufacturers focus first on quality when making wire harnesses and cable assemblies for medical devices.

January 15, 2018

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing