Assembly in Action

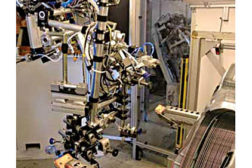

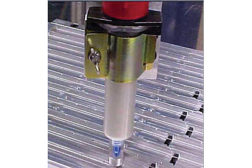

Assembly In Action: 3D Printer Prototypes Complex, Multi-Material Parts

The machine can create prototypes made of flexible and rigid materials

February 1, 2012

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing