Home » Keywords: » linear actuator

Items Tagged with 'linear actuator'

ARTICLES

Precision Motion Control Helps Map the Universe

Precision motion control technology is helping astrophysicists map stars, galaxies and black holes.

June 13, 2023

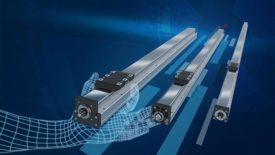

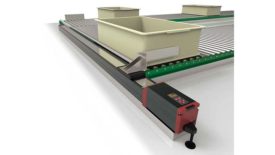

What’s New With Pneumatic Actuators

Available in many configurations, pneumatic actuators remain essential workhorses of machine motion and increasingly are being made adaptable to the IIoT plant floor

February 6, 2020

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing