Home » Keywords: » linear actuators

Items Tagged with 'linear actuators'

ARTICLES

Maintaining Control in Vertical Ballscrew Applications

A spring-engaged, air-released servomotor brake can prevent back-driving of a ballscrew in vertical motion applications.

October 3, 2016

advertisement

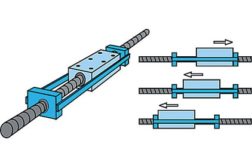

How To Simplify the Process of Specifying Air Cylinders for Operation in Tight Spaces

March 8, 2016

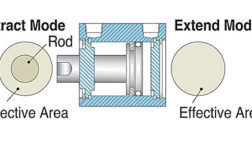

How to Specify Pneumatic Cylinders

Stroke length, force requirements, and operating environment are among the many considerations when specifying pneumatic cylinders.

September 3, 2014

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing