Home » Keywords: » vision sensors

Items Tagged with 'vision sensors'

ARTICLES

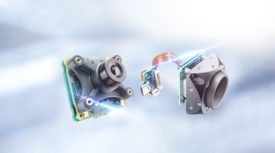

What’s New With Machine Vision Systems

New technology is making vision systems faster, more reliable and easier to use.

November 7, 2016

What’s New With Sensors

New technology is helping to make sensors smaller, more robust and easier to integrate.

June 3, 2016

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing