Home » Keywords: » force sensors

Items Tagged with 'force sensors'

ARTICLES

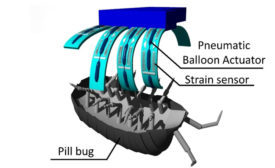

Force-Controlled Assembly With Robots

Tactile sensing technology opens up new applications for automation

February 1, 2019

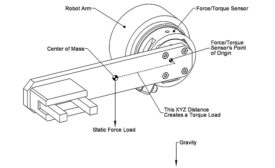

Force and Torque Sensors

Advanced technologies increase the accuracy of force and torque sensors used in product assembly and end-of-line testing.

June 7, 2017

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing