Developing an automated manufacturing strategy for new products in today’s climate can be a gamble with the unknown. Accurately predicting the demand curve is nearly impossible, which makes securing funding difficult. Now, more than ever, we need technology that allows us to align production capability to highly dynamic market demand.

This has been difficult for traditional assembly lines, which can only accommodate a relatively small number of model variations. When assembly processes are arranged in sequential order, true flexibility in terms of production volume or investment timetables is lost. Essentially, the traditional assembly line is an all or nothing manufacturing strategy.

Flexibility is now becoming a reality, not only in terms of product variations, but also in production volumes and investment capital. Comau Inc. has developed an assembly machine architecture called Smart Cell that does just that. “We developed our Smart Cell system to align production capacity to market demand,” says Ted Brown, vice president and general manager of Comau. “This provides the customer with investment flexibility, production flexibility and product flexibility. It also improves speed to market and reduces fixed and variable costs.”

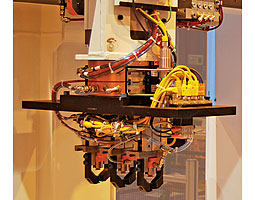

The Smart Cell is essentially a large Cartesian robot with a central pallet-positioning system and two mobile vertical axes, rather than one. Instead of a single, dedicated end-effector that only changes when a new model is being made, each robot arm is equipped with a tool changer from ATI Industrial Automation so end-effectors can be swapped continuously during the assembly sequence. The end-effectors are mounted to special, compact tooling plates, or “shoe boxes,” that reside inside the cell. The Smart Cell can hold eight shoe box tools.

With two tooling arms, one is always working, while the other is reconfiguring for the next step in the sequence. Production is continuous and uninterrupted.

“Any assembly tooling can be packaged into one of our tooling plates,” says Brown. “You can install snap rings, run down bolts, insert springs, dispense fluids, pick and place parts-whatever you need. With the Smart Cell, you only have to design the end tools; you don’t have to design the machine anymore.”

With all assembly functions incorporated into one standardized cell, production planners have complete scalability. By investing in only one cell, production can start immediately in a very small facility with reasonable production levels. As demand grows, assemblers can simply add more Smart Cells in parallel to match sales.

Perkins Engines Co. has already purchased two systems for its plant in Peterborough, England. The machines will be used to assemble cylinder heads.

“To produce cylinder heads with a traditional serial process, separate machines would press in the seals, flip the part over, install the intake valves, install the exhaust valves, flip the part back over, take out the cam caps, install the springs, put in the retainers and collets, perform a leak test, and reinstall the cam caps,” says Brown. “That’s nine to 12 separate machines, plus conveyors, PLCs, control panels and pallet locators. Each of those machines has a 25-second cycle time. The Smart Cell does the same job with one machine in 52 to 54 seconds. And, you only have one part in process, as opposed to 18 to 24 parts.”

To streamline the wiring and make the most use of the IO-Link technology, Comau used new pneumatic cylinder position sensors from Balluff. Combining two sensors into one connection, the sensors provide both open and closed position feedback for all cylinders mounted on the shoe box tooling through one connector.

Enabling Technology

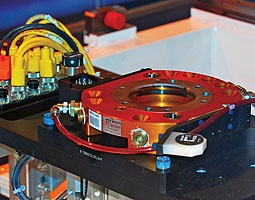

A key engineering challenge faced by the Comau design team was how to achieve good production rates and high reliability despite a large number of tool changes. The shoe box tools have up to 16 sensors and pneumatic clamps that require rapid and continuous changes. “We had to keep our tool change time down to a minimum and remove as many points of potential failure as possible,” says Gary Beebe, controls engineer for Comau. “For reliability and simplicity, we looked at passing Profibus down to the shoe box tool, but the availability time after a tool change was too long.”Understanding how critical tool change time and reliability would be, the search was on for a new technology. Balluff Inc. recommended using a new connection technology called IO-Link. As a transparent extension of Comau’s existing Profibus network, IO-Link enabled reliable connections through standard cabling to small, machine-mounted I/O blocks located directly on the shoe box tooling. “The real payback was in the boot-up time of the IO-Link blocks,” says Beebe. “IO-Link is up and running in well under one second with no disruption to our Profibus system.”

Due to the volume of tool changes, maintaining reliability with the traditional mechanical pin-based based connection systems was a concern. Responding to this need, Balluff developed a solid-state, noncontact connection system that supported IO-Link. Operating off the inductive coupling principle, the IO-Link coupler passes power for the sensors and the IO-Link communications signals through an air gap and down to the shoe box tool. Concerns over reliability were eliminated along with the high-wear mechanical pins.

To eliminate human error, tool tracking was required to ensure the correct shoe box tool was being used. Radio frequency identification (RFID) was the logical choice. Balluff provided an RFID system with an integrated IO-Link interface. Now, the tool-mounted RFID tag can be seamlessly read through the system to ensure uninterrupted machine operations in the event of a misplaced shoe box tool.

To streamline the wiring and make the most use of the IO-Link technology, Comau used new pneumatic cylinder position sensors from Balluff. Combining two sensors into one connection, Balluff’s V-Twin magnetic field sensors provide both open and closed position feedback for all cylinders mounted on the shoe box tooling through one connector.

Comau now has a robust and high-speed communications technology that can reliably accomplish the number of tool changes required by the Smart Cell system.

A key challenge faced by the Comau design team was how to achieve high reliability despite a large number of tool changes. IO-Link from Balluff enabled reliable connections through standard cabling to small, machine-mounted I/O blocks located directly on the shoe box tooling.

Customer Payback

With Balluff’s IO-Link technology, the Smart Cell offers significant benefits in scalability and cost. At the start of production, manufacturers can limit their investment risk by using a single Smart Cell. As product demand increases and capital becomes available, more Smart Cells can be added in parallel to increase production. At the end of a product’s life cycle, Smart Cells can be easily repurposed to other growing products with simple shoe box tool changes.By implementing Smart Cells, manufacturers can dramatically reduce costs. Compared with a traditional assembly line, “fixed and variable costs are reduced by 40 percent, floor space is reduced by 60 percent, and the number of automation components is reduced by 75 percent,” says Brown.

Those are impressive numbers by any measure.

For more information on the Smart Cell, visitwww.comau.comor contact Brent Kelso of Comau at Brent.Kelso@comauinc.com.

For more information on tool changers, visitwww.ati-ia.comor call 919-772-0115.

For more information on IO-Link products, visitwww.balluff.com/iolinkor call 800-543-8390.