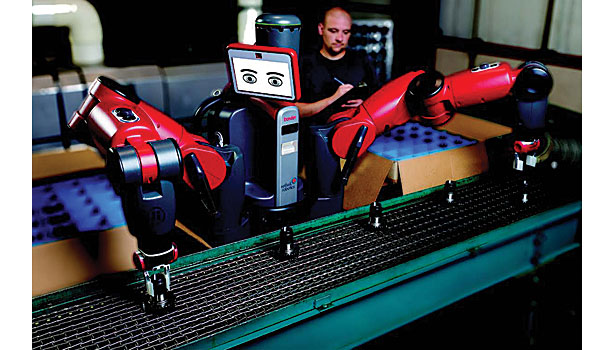

Kids have loved robots and toys for generations. The Rodon Group has decided that now is the perfect time for a robot named Baxter to help pack toys in the company’s highly automated manufacturing facility.

Baxter is the brainchild of Boston-based Rethink Robotics Inc., which developed the robot to perform simple repetitive tasks—line loading and unloading, and basic packing and unpacking—so human operators can focus on more value-added jobs. Rethink Robotics hopes this shift in duties will help American manufacturers gain a competitive advantage in the marketplace and prevent them from going offshore.

In business since 1956, The Rodon Group uses more than 100 plastic-injection-molding presses to produce billions of parts each year in its 125,000-square-foot facility. This extremely high volume makes Rodon one of the largest family-owned and operated plastic-injection molders in the United States.

Since 1992, Rodon has been a subsidiary of K’NEX Brands L.P. and has manufactured more than 30 billion parts for the K’NEX building toy system, which is one of the world’s most-popular integrated construction systems for children.

Rodon uses Baxter to pack tracks that come with Mario Kart Wii racing sets. However, the company hopes to eventually have Baxter perform several other tasks. These include light assembly, material handling, machine tending, testing and sorting, and finishing operations.

Unlike traditional two-arm robots, Baxter features behavior-based intelligence that constantly adapts to the manufacturing environment. Built-in sensors make Baxter ‘aware’ of its surroundings, so to speak, enabling the robot to work cooperatively and safely with people without guarding or enclosures.

Equally important, Baxter is easy to train. People that work alongside Baxter can show the robot how to perform a task and repurpose it as needed. No lines of programming are necessary. Within a few hours of testing, Baxter was packing boxes on the Rodon factory floor.

The robot uses five built-in cameras for object identification, and it performs eight to 12 pick-and-place operations per minute. Baxter has a rated life of 6,500 hours.

Each arm has a 5-pound payload, offers seven degrees of freedom and moves at 1 meter per second. It is 41 inches long (to the end-effector plate) and features force sensing and control at the elbow and wrist joints.

Baxter weighs 165 pounds and is 37 inches tall. It has a fully extensible platform that includes all necessary software, which can be updated to enhance capabilities and performance. A software development kit enables users to customize tasks.

For more information on adaptive robots, call 617-500-2487 or visit www.rethinkrobotics.com.