Looks can sometimes be deceiving in a positive way. A good example is the t:slim insulin pump made by Tandem Diabetes Care Inc.

Introduced in June 2012, the t:slim looks more like a smartphone than an insulin pump. It has the footprint of a credit card and features a leakproof aluminum case, a rechargeable polymer lithium battery and a micro-USB port, which can deliver data to clinicians if necessary.

The device is the smallest insulin pump on the market, weighing a bit less than 4 ounces and measuring 2-by-3.13-by-0.6 inch. It also is the first insulin pump with a touch screen, which is made of shatter-resistant glass.

Manufactured in San Diego, the t:slim consists of several subassemblies. Some are built manually, while others—such as the micro-delivery chamber—are made on automated equipment to save energy, materials and floor space.

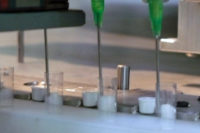

Tandem uses an Intelligent Desktop Automation (IDeA) platform from JOT Automation Ltd. to assemble the chamber, which is located within the device’s supply cartridge. IDeA performs several functions, including pick-and-place, adhesive dispensing and curing, and visual inspection of all chamber components. JOT was selected because of its track record of helping electronics manufacturers improve their assembly processes.

During pump operation, insulin is drawn from a reservoir (300-unit capacity) into the chamber and then dispensed through an infusion line. Unlike traditional syringe pumps, which compress a reservoir’s full volume, the micro-delivery chamber draws and delivers insulin in increments as fine as 0.001 unit per hour, at rates above 0.1 unit per hour.

Launched in early 2012, the IDeA platform easily adapts to a wide range of applications and is suitable for in-line and off-line processes. It features a wireless tablet-based user interface with real-time status information. The one interface can be used for multiple workcells.

Work areas range from 130-by-250-by-100 millimeters, to 260-by-260-by-100 millimeters. Platform width is 335 or 535 millimeters, depth is 600 millimeters and payload is 0.5 kilogram.

For more information on desktop platforms for automated assembly, call 858-255-8808 or visit www.jotautomation.com.