Canadian-based PCB manufacturer Candor Industries Inc. is well known in the industry for its ability to produce prototype standard circuit boards very quickly—often within 24 hours. More complex prototypes can be completed in three days and be in full production within 10.

Founded in 1999 by Yogen Patel, the company thrives on pushing the envelope of PCB manufacturing through continuous R&D. Several years ago, for example, Patel developed a positive acting liquid photoresist process that eliminates the need for many dangerous chemicals traditionally used in PCB fabrication. Since then the company works without formaldehyde dry-film and tin-lead resists, ammonia-based etch chemistry and all associated byproducts.

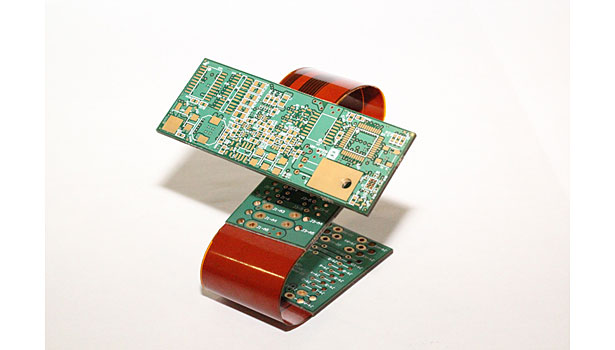

Equally important, the photoresist process produces boards with vias that do not need to be plated with an annular ring. (Vias are through holes that connect conductors on different layers of multilayer PCBs.) Eliminating the annular ring enables engineers to more easily design multilayer boards, large PCBs or those with high wiring density.

Earlier this year, Candor upgraded its automated optical inspection (AOI) system to improve PCB quality. With AOI, a camera autonomously scans the PCB for various surface feature defects such as scratches, stains, open circuits, short circuits and thinning of the solder. It also checks for missing, incorrect and incorrectly placed components.

The company installed an Orion PX system, which scans both sides of a PCB in a single cycle. Made by Camtek USA Inc., Orion PX delivers throughput of up to 200 sides per hour based on a 24-by-18-inch panel (or cluster of PCBs).

“This system is 10 times faster than its predecessor, and it enables us to deliver quality multilayer boards with added complexity,” explains Sunny Patel, quality management representative and technical sales manager for Candor Industries Inc.

The system is specially engineered to meet high-end PCB inspection requirements starting at 1.2-mil (0.0012 inch) lines and spaces. It features a Spark cross-platform engine that offers multi-zone detection of low-contrast materials such as drum-side and double-treated foil, and white Teflon.

Patel says Candor likes that the system offers simple setup for various-width lines and spaces, inspects mixed units in the same panel and eliminates false alarms sometimes caused by panel dimensional variation. He adds that the system’s illumination block and operating software also enhance inspection of the company’s flexible PCBs.

For more information on automated optical inspection systems, call 800-986-9540 or visit www.camtekusa.com.