CAMBRIDGE, MA—Engineers at the Massachusetts Institute of Technology (MIT) have developed a way for robots to home in on moving objects with unprecedented speed and accuracy. The RFID-based system could enable greater collaboration and precision by robots working on assembly lines.

Robots using the system can locate tagged objects within 8 milliseconds, on average, and with an error of less than a centimeter. The TurboTrack system uses radio-frequency identification (RFID) tags to track objects.

A reader sends a wireless signal that reflects off the RFID tag and other nearby objects, and rebounds to the reader. An algorithm sifts through all the reflected signals to find the RFID tag’s response. Final computations then leverage the RFID tag’s movement to improve its localization accuracy.

“The system could replace computer vision for some robotic tasks,” says Fadel Adib, an assistant professor and principal investigator in the MIT Media Lab, and founding director of the Signal Kinetics Research Group. “As with its human counterpart, computer vision is limited by what it can see, and it can fail to notice objects in cluttered environments.

“Radio frequency signals have no such restrictions,” explains Adib. “They can identify targets without visualization, within clutter and through walls.”

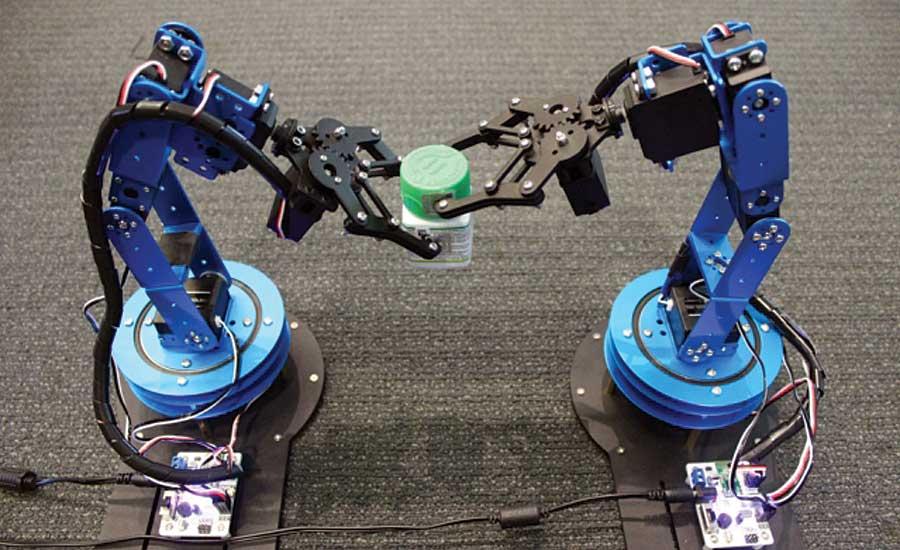

To validate the system, Adib and his colleagues attached one RFID tag to a cap and another to a bottle. A robotic arm located the cap and placed it onto the bottle, held by another robotic arm.

In another demonstration, they tracked RFID-equipped nanodrones during docking, maneuvering and flying. In both tasks, the system was as accurate and fast as traditional computer vision systems.

“If you use radio frequency signals for tasks typically done using computer vision, not only do you enable robots to do human things, but you can also enable them to do super human things,” notes Adib. “And, you can do it in a scalable way, because these RFID tags are only 3 cents each.”

“In manufacturing, the system could enable robotic arms to be more precise and versatile in, say, picking up, assembling and packaging items along an assembly line,” says Adib.

“Similar systems have attempted to use RFID tags for localization tasks,” Adib points out. “But, these come with trade-offs in either accuracy or speed. To be accurate, it may take them several seconds to find a moving object; to increase speed, they lose accuracy.”

The challenge is achieving both speed and accuracy simultaneously. To do so, Adib and his colleagues drew inspiration from an imaging technique called “super-resolution imaging.”

“These systems stitch together images from multiple angles to achieve a finer-resolution image,” says Adib. “The idea was to apply these super-resolution systems to radio signals. As something moves, you get more perspectives in tracking it, so you can exploit the movement for accuracy.”

The system combines a standard RFID reader with a “helper” component that’s used to localize radio frequency signals. The helper shoots out a wideband signal comprising multiple frequencies, building on a modulation scheme used in wireless communication called orthogonal frequency-division multiplexing.

The system captures all the signals rebounding off objects in the environment, including the RFID tag. One of those signals carries a signal that’s specific to the specific RFID tag, because RFID signals reflect and absorb an incoming signal in a certain pattern, corresponding to bits of 0s and 1s, that the system can recognize.

“Because these signals travel at the speed of light, the system can compute a ‘time of flight,’ measuring distance by calculating the time it takes a signal to travel between a transmitter and receiver,” says Adib. “[This is used] to gauge the location of the tag, as well as the other objects in the environment.”