Exhibitors brought the latest technologies for plastics assembly to The ASSEMBLY Show last fall. The following are just some of the plastics assembly equipment on display at the show.

Station for Infrared Staking, Welding

Extol Inc. has released the IAS 713, a benchtop plastics-joining station for use with the company’s InfraStake and InfraWeld modules. The station is a complete turnkey system consisting of a base frame, an InfraView power supply and controller, and InfraStake or InfraWeld modules with part fixturing.

The station features the new InfraView controller and power supply, which provides intuitive setup and process control, both full-stroke and boss-presence verification inputs, and automatic recipe selection based on sensor inputs. Operators can add, subtract, edit, and sequence inputs and outputs from the HMI. The InfraView is equipped with a 7-inch, color, high-resolution HMI screen, and it can display information in different languages.

The station also includes a 10-inch press stroke, a large operating window for taller parts, a 7-by-13-inch aluminum upper tooling platen, and the ability to control and cycle up to 12 InfraStake or InfraWeld modules simultaneously. Dual Opto-Touch start switches and an e-stop switch are integrated into the base.

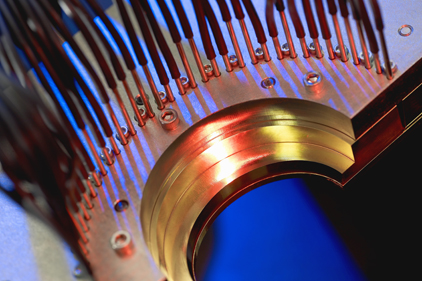

Contoured Laser Welds Plastic

Contoured laser technology (CLT) from Branson Ultrasonics Corp. employs an exclusive process called simultaneous through-transmission infrared welding. Simultaneous welding equates to speed, uniform collapse, and low localized power density.

Laser energy produced by laser diodes passes through one plastic component (the transmissive component), and then is absorbed at the bond line by the second component (the absorptive component). This absorption heats and melts the entire joint surface simultaneously while the two parts are held together under precisely controlled pressure. The result is a strong, uniform weld, with less risk of rejects due to surface imperfections.

Laser-emitting wave guides conform exactly to the contours of the part surfaces they are to join, melting the entire interface at once for fast, uniform weld joints. CLT can be configured with one laser bank with 125 watts of power for welding small parts (such as ink cartridges) or with up to four laser banks with 500 watts of power for welding larger parts (such as instrument clusters). Weld times range from 0.5 to 5 seconds.

Two standard models of CLT welder controllers are available. The 3G is a compact benchtop controller designed to interface with a 2000X actuator and one or two CLT laser banks capable of delivering up to 250 watts of laser power. The 3I is a free-standing controller designed to interface with a 2000X actuator and up to four CLT laser banks capable of delivering up to 500 watts of laser power. Both systems allow engineers to control and monitor weld time, distance and force.

The clean welds created with CLT are virtually free of particulates that can complicate downstream manufacturing or compromise aesthetics and product performance.

For applications that require internal components to be held in place during welding, CLT allows for parts to be placed into the welder in the same position and orientation as the final, assembled position demands.

CLT has successfully welded a broad range of materials, including polycarbonate, polyamide, polystyrene, ABS, elastomers (TPU/TPE), polypropylene, high- and low-density polyethylene, polyethylene terephthalate, polybutylene terephthalate, polyphenylene sulfide and PMMA.

Servo Welder Ensures Accuracy, Repeatability

Dukane Corp. showed its iQ advanced servo welder.

The welder’s electric servo press eliminates the variability associated with pneumatic presses, resulting in better process repeatability and accuracy. Dynamic servo motion control enables precise control over the velocity, force and position of the ultrasonic stack, providing a more optimized and robust process.

The Dynamic Velocity Melt Initiation feature provides precise control over velocity and force during initial application of sonic energy, allowing engineers to optimize the start of plastic melting at the joint line.

The welder’s Melt-Match feature precisely matches the velocity of the ultrasonic stack with the melt-flow velocity of the plastic material, ensuring optimum molecular intermingling. This produces stronger, more reliable welds.

In addition, engineers can program the speed of the ram, including multipoint velocity profiles. Hold time after welding can be programmed statically or dynamically (by distance).

The welder’s digitally controlled power supply has a 0.5-millisecond multicore processing rate, collecting twice as many data points during the welding cycle than other ultrasonic power supplies. The increased processing speed improves repeatability and enhances the reliability of the welding output and programmed quality controls. Digi-Trac tuning automatically tracks the resonant frequency digitally, adjusting the output frequency to match the acoustic stack (sonotrode, booster and transducer). Load regulation provides constant ultrasound amplitude automatically regardless of the power draw. Amplitude level is held to within ±1 percent.

The welder’s HMI includes a 15-inch color industrial PC with touch screen, a compact flash solid-state drive (no moving parts), two USB ports, and one Ethernet port. The welder’s Windows operating system uses familiar file folder menu structure and requires no special training to program and operate. All setup parameters are programmed from one menu page.

The 20-kilohertz model has a 5-inch stroke and produces 560 pounds of force; the 30-, 40- and 50-kilohertz models have a 3.5-inch stroke and produce 150 pounds of force. Stroke length is adjustable in 0.001-inch increments. The welder’s linear distance encoder has a resolution of 1 micron. The home position of the ram is programmable to reduce cycle time and optimize setup.

Two-stage programmable down speed allows for a fast approach prior to trigger, reducing cycle time. Trigger force is programmable in 0.1-pound increments for welding precise, delicate assemblies. The welder also offers trigger by power or pretrigger by distance modes.

There are two programmable motion control modes. Speed mode allows for either constant or 10-segment velocity profile during weld phase. Force mode allows for either constant or 10-segment force profile during weld phase. Engineers can also weld by time, energy, distance, absolute distance, or peak power. Hold time can be static or dynamic.

Spin Welders Join Round Parts

In spin welding, one part, which has a circular cross section at the weld interface, is rapidly spun against its mating part, which is held stationary in a fixture. The resulting heat that is generated by the combination of spinning action and friction brings the plastic to its melt point and fuses the two parts together, producing a strong and impervious seal. Hermetic seals are also attainable depending upon the materials and the joint configuration.

While spin welding works with all thermoplastics, and can accommodate virtually any diameter part, it is particularly suited for crystalline resins such as polyethylene and polypropylene.

Sonics & Materials Inc. offers two standard spin welders. Model 1010 features a fixed, vertical opening that provides 10 inches of space between the drive head bearing and the fixture platen. Model 1020 offers an adjustable space opening from 10 to 20 inches. Both models accommodate a wide range of application tooling and allow for easy part loading and unloading.

These PLC-controlled welders can operate in single- or two-stage cycle modes. Weld time, speed and other parameters are input through the PLC’s front-panel operator interface.

The drive head—the tool that holds the part to be spun—is attached to the drive bearing of the spin motor. Typically, the heads are fabricated from aluminum and are either two-piece, compression spring loaded for single-stage spin welding or, are cast with a urethane core for vacuum-assisted, two-stage spin welding. The fixture is holds the stationary part in a fixed position during the welding process. It is attached to the tooling platen directly beneath—and opposite—the drive head. Fixtures are typically made of aluminum and occasionally require pneumatic or mechanical clamping to prevent the plastic part from “spinning out” during the weld cycle.

Speed and torque settings vary depending on the plastic and the diameter of the part to be welded.

Torsional Ultrasonic Welding

Telsonic Ultrasonics Inc. showed its Soniqtwist process, a high-frequency friction welding procedure that falls somewhere between vibration welding and ultrasonic welding.

The sonotrode oscillates torsionally around its longitudinal axis in both directions. In a short amount of time—between 0.1 and 0.4 second—a large amount of vibrational energy (frequency of 20 kilohertz and amplitude of up to 80 microns) is applied to the boundary surface of both parts. This boundary friction enables both parts to be joined firmly and safely.

The design of the torsional welder is similar to conventional ultrasonic welding equipment, with generator, converter and sonotrode. However, in contrast to conventional systems, the sonotrode no longer oscillates longitudinally, but torsionally. This reduces the load on the components.

However, the underlying functional principle is identical. Electric vibrations produced by a generator are converted into mechanical oscillation by means of a piezoelectric transducer. Linear vibrations are converted into torsional vibrations through acoustic components in the oscillating head of the welder.

The generator works at a frequency of 20 kilohertz and up to four converters can be applied with one sonotrode. Thus, a maximum capacity of 10 kilowatts is available.

Upon switching off the ultrasonic power, the sonotrode immediately returns to its initial position without any offset of the parts. No external heat supply is needed.

All parameters, such as frequency, weld depth and weld time, can be adjusted and monitored.

Even with difficult materials, the process produces joint strengths that can be hard to achieve with conventional ultrasonic welding. Pull-off strengths of 500 newtons or more can be achieved, depending on the component and requirements. “Far field” welds can also be achieved. The process is many times faster than friction welding, depending on amplitude and force applied by the ultrasonic welding tool.

Rotary Indexing Machine for Heat Staking, Insertion

Plastic Assembly Systems has developed the Model 50IASR, a true, closed-loop heat-staking machine with a rotary indexing table for high-volume production of small- to medium-sized assemblies that require SPC feedback.

Heat-staking and insertion are accomplished with direct-contact heated tools. Time, temperature, pressure, and cooling are precisely controlled to reform plastic studs, walls or protrusions, or to embed metal components into plastic. Unlike other methods of plastics jointing, heated tools can perform multiple operations on several planes simultaneously. Cycle times are relatively fast. Cosmetics are exceptional. Staked parts appear to be an extension of the molding process.

The controller monitors every parameter of the process. The controller monitors exactly how long it takes to make a complete part from start to retraction of the tool, and it alerts the operator when the system took too long to complete an assembly. The controller also alerts the operator to excessive travel by the insertion head.

The controller checks the tool temperature prior to every cycle to ensure proper operating temperature. Multiple tools in one setup can be set to different temperatures.

The rotary indexer is available with two, four, six or eight positions.

Recent Comments

Helpful for Trainees

Cable Assembly Manufacturers

Huawei for manufacturing?

should have a scanner and then 3D print the repair

IPC-A-610 and IPC-j-std-001