One of the biggest questions surrounding structural adhesives is, “How do I know the bond is good?” Bonded joints are tested under many conditions during development, but those tests are destructive tests. New types of nondestrutive testing allow engineers to detect kissing disbonds.

One of the biggest questions surrounding structural adhesives is, “How do I know the bond is good?” Bonded joints are tested under many conditions during development, but those tests are destructive tests. A joint that has been broken proves it used to be good. How do we examine the quality of an adhesive bond using nondestructive testing?

Whether the methods are referred to as nondestructive testing (NDT), nondestructive evaluation (NDE) or nondestructive interrogation (NDI), they all send energy into a joint region and detect a recordable disruption based on the interaction of that energy and the bonded area. Some type of signal change takes place and a typical measurement depends on the difference between the signal going in and the signal coming out. The measured difference may relate to time delay, phase delay, frequency shift or signal attenuation.

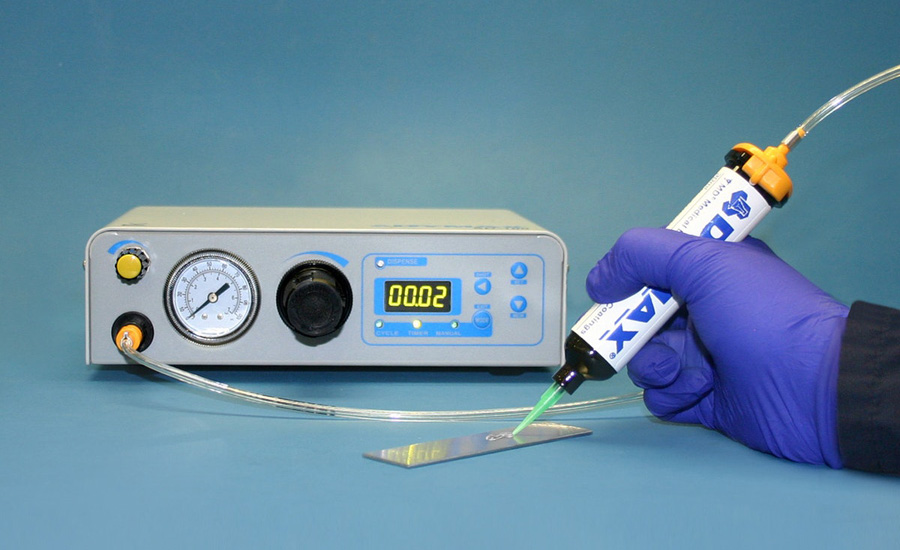

The energy may be delivered by ultrasonic probes, laser probes, thermal probes, mechanical disrupters or combinations of them. For adhesive applications, the most common methods employ ultrasonic energy. Ultrasonic waves are created in a transducer, often a piezoelectric device that converts electrical energy into sound energy. The ultrasonic frequency is often quite high, ranging from 100 kilohertz to several megahertz. With higher frequency comes better resolution, although available power is lower.

Newer techniques employ phased-array ultrasonics similar to those used in medical ultrasonic imaging. Many small transducer cells are arrayed and driven sequentially by individual energy pulses. There may be several dozen cells in the scanning head.

Varying the pulse timing from cell to cell produces a phased array of ultrasound energy that sweeps the bond area. The resulting reflections have a phase delay proportional to the distance they travel, what they encounter in their path, and how much attenuation they experience. The displayed result is the familiar pictograph, which gives considerable detail and resolution. This is the method we use at EWI to look at welds; we have also adapted it to look at adhesive bond lines.

Dissimilar materials in the joint, from bonding plastic-to-metal or composite-to-metal, introduce other difficulties. Ultrasonic waves are sensitive to discontinuities produced by wide differences in density or attenuation. The velocity and attenuation of sound in each material are different, resulting in varying degrees of signal attenuation and reflection.

Adhesives have properties similar to plastic, making it difficult to discern the adhesive-plastic interface. The sharply contrasting adhesive-metal interface reflects well, but the signal travelling back through the adhesive is significantly attenuated. On a thick adhesive bond line with any material, signal attenuation can be more than 95 percent.

This is where electronic techniques come into play. Signal averaging and signal processing are used to increase signal-to-noise ratio. Along with the phased array approaches, this gives marked improvement in sensitivity.

A promising new method was recently developed. A measured pulse of laser energy is introduced onto the surface, which creates a mechanical mini shock wave. The reflected wave is detected and the difference in laser energy in-and-out is determined. As the energy is increased, at some point the shock wave will break the bond in one pinpoint area, which prevents the reflection from travelling back.

The bond strength is then equal to the original incident energy. Because the debonded area is small, it does not compromise the performance of the joint. This is one of the few techniques that actually measures bond strength, not just bond integrity or quality.

What are we looking for? It is relatively easy to find voids or missing adhesive. The nemesis is the so-called “kissing disbond,” which is caused by having adhesive in contact with the bonding surface, but having no bond strength. This cannot be detected using simple ultrasonics.

Methods based on signal processing and introduced shear waves along with incident waves can be useful in detecting kissing disbonds. The laser method mentioned above has the greatest likelihood of detecting a kissing disbond, since the reflected shock wave is stopped at the disbond.

No one trusts what they can’t measure or know. The traditional methods of destructive testing during development followed by statistical reduction of load allowance are good. But, being able to quantitatively assess the health of a bond is an important next step in furthering the use of structural adhesives.

Bonding Lines: How Good Is Good?