Interference fits, commonly referred to as press fits and shrink fits, are traditional methods for joining cylindrical parts. In an interference fit, the inner part—such as a shaft, bearing or bushing—is machined to be bigger than the mating hole of the outer part—such as a gear or housing. The larger part is then forced into the smaller part. Both parts deform slightly to fit together and extremely high friction results between them. The friction is so great that even large amounts of torque cannot separate the parts. They operate as one.

For maximum joint strength and optimal performance, interference fits must be highly precise. Engineers go to great pains to calculate and achieve the appropriate allowance that will provide maximum friction between the parts. This dimensional precision increases both the cost and the time required for component production.

A reliable interference fit puts high levels of stress on the joined components, which limits substrate selection. Only certain materials can withstand the stresses of machining and the forces required to merge the parts. For example, an engineer may not be able to select powdered metal or aluminum for a component because steel is required to achieve the target joint strength.

Adhesives called retaining compounds enable engineers to design robust, lightweight joints at less cost than traditional interference fits by reducing dimensional precision and increasing the selection of viable substrate materials. Retaining compounds provide strength and reliability and are commonly used to secure bearings, bushings, gears and cylindrical parts onto housings or shafts.

Retaining Compounds

Retaining compounds are anaerobic structural adhesives that polymerize when the liquid is confined without air between close-fitting metal surfaces. The first and best-known use for anaerobic adhesives is thread-locking, in which a drop of adhesive applied to the threads of a nut and bolt bonds the assembly, prevents vibrational loosening, seals the threads against fluids and moisture, and prevents corrosion and rusting. Manufacturers embraced anaerobic threadlockers as a chemical solution to the mechanical problem of loosening.

Engineers soon discovered another use for anaerobic adhesives: assembling cylindrical metal parts. The retaining compound fills the empty space between the mating surfaces and cures to chemically unitize the assembly. The combination of an interference fit and a retaining compound is much stronger than an interference fit alone.

The cured adhesive fills the inner space between the components and provides a physical and chemical barrier that eliminates fretting, oxidation and galvanic corrosion. The adhesive also seals the interference fit joint against leakage.

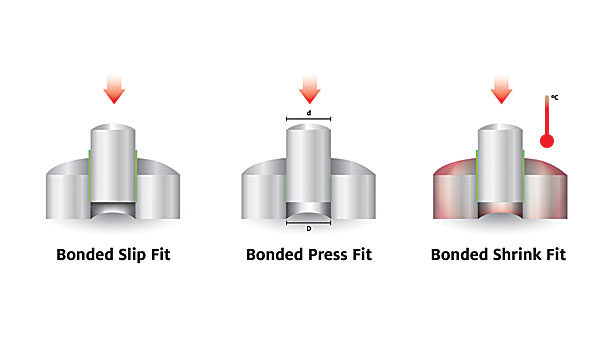

Retaining compounds are used in three ways for interference fit joints:

- added to existing interference fit designs to increase joint strength and reliability.

- engineered into new interference fit designs to create smaller, lighter weight assemblies. The parts can be made with relaxed tolerances requiring lower cost machining.

- used to structurally bond a slip fit that eliminates the need for an interference fit. The parts do not need to be machined to tight tolerances, and the joint is as reliable and effective as an interference fit.

Retaining compounds increase the strength and reliability of a traditional interference fit. Interference fits generate strength from the metal to metal contact of surface peaks, which represent only 15 percent of the total surface area of the joint. The liquid retaining compound fills the surface irregularities and clearance gaps between the two parts. It then cures to create a dense, high-strength bond that increases joint strength and achieves maximum load transmission. The cured resin increases the area of surface contact so stress distribution is improved. This enhances joint reliability, reduces equipment downtime and increases part life.

Whether it’s an interference fit or a slip fit, components bonded with retaining compounds do not require precise dimensions or a fine surface finish. Bonded interference and slip fits allow relaxed tolerances that are ideal for joining dissimilar metals and translate into lower-cost processing for components. Bonded assemblies experience less stress in the joint and are more robust under differential thermal expansion. So when different substrates are bonded, the assembly maintains its strength better, since the joint does not depend on the interference fit alone.

Retaining compounds prevent fretting corrosion in interference fits. Fretting corrosion results when micro-movement occurs between a bearing and a shaft or housing, causing small sections of the assembly to weld together. When the assembly moves the next time, these small welded sections rip off and result in a cratered surface. By filling the inner space between interference-fit parts, retaining compounds prevent this micro-movement.

Retaining compounds also serve as a sealant that prevents corrosion and leakage and provides a physical and chemical barrier to oxidation and galvanic corrosion. These adhesives are often used to seal core plugs into an engine block and to close off the outer diameter of a rotary seal installed into a housing.

Retaining compounds can replace brazing and welding with a quick and simple process that does not require specialized equipment or skilled operators. Unlike brazing and welding, retaining adhesives do not produce hazardous fumes. Bonding is also faster than brazing or welding.

Application and Removal

In their liquid form, retaining compounds may be applied using manual, semiautomatic and fully automatic dispensing equipment.

An example of a fully automatic dispenser is the Rotospray applicator. This device applies a metered amount of adhesive in a 360-degree bead or band onto a predefined location in the bore of a part. Application is precise and repeatable. The applicator can be positioned in any axis and operated in either semiautomatic or fully automatic mode.

Hand pumps are precision applicators for manual dispensing that control the volume and location of adhesive. The heart of the hand pump is an adjustable-stroke peristaltic pump that dispenses a metered amount of adhesive each time it is manually actuated.

Parts assembled with retaining compounds come apart with the standard disassembly methods for press- and shrink-fit components. These methods range from gear pullers to hydraulic oil injection to hydraulic presses. No special processing steps are required to break the adhesive bond.

Retaining compounds are available in medium- and high-strength formulations. A medium-strength retaining compound may be preferred for a joint designed for routine disassembly.

Advancements in Chemical Retaining

Recent advancements have made retaining compounds more robust for today’s process and performance requirements. Formulated for simplified processing, the latest compounds do not require primers or activators to enhance cure speed or strengthen bonds. Once assembled, they resist higher temperatures than earlier formulations.

Surface cleaning and preparation processes continuously evolve as a result of environmental, safety, regulatory and cost-saving initiatives. While clean bonding surfaces deliver the best results for any assembly, the newest oil-tolerant retaining compounds are formulated to cut through light oils and surface contaminants. The result is consistent bond strength despite variations in the cleaning process.

Engineers employ a wide range of substrates and coatings when designing interference or slip fit assemblies. For example, aluminum is used for weight reduction and stainless steel for chemical resistance. Historically, a chemical activator or primer had to be applied to nonferrous parts to cure the retaining compound. The newest primerless compounds cure on these surfaces as well as they cure on steel. The primer is no longer required to achieve polymerization,

making the process more robust and eliminating an assembly step.

Size, weight and efficiency are key parameters for most new interference or slip fit designs, targets that drive assemblies to higher operating temperatures. The latest heat-resistant retaining compounds can withstand continuous operating temperatures to 180 C. Even when high temperature capability is not required, these formulations increase the safety and robustness of the assembly.

Typical Applications

Manufacturers use retaining compounds to lower costs, increase performance and improve reliability. These are just a few real-world examples of their use in industrial applications.

To reduce stress concentrations and potential premature failure, a slip-fit bonded with an anaerobic retaining compound replaced an interference fit on the lobe of the eccentric shaft of a brushless motor. The new design enhances overall strength of the assembly and helps it operate over a sufficient temperature range, resist lubricating oils and withstand torsional stress. Loctite 7649 primer cleans the surface, accelerates cure and allows larger gaps to be filled. Loctite 620 high-temperature retaining compound grips the metal and locks the parts together. The new design relaxes tolerances and reduces part costs, simplifying alignment and reducing stress.

On large air bearings, steel threaded inserts are bonded to the 18-guage galvanized steel bearing surface using a retaining compound. This eliminated spot welding and the extra cleaning step to remove oxides from the surfaces. Loctite 638 retaining compound made the assembly process simpler and faster, lowered overall production costs, increased process safety and reduced work in process.

On industrial radiators, a time-consuming and costly brazing process on heat exchanger tubes was replaced with a slip-fit bonded with retaining compound. To eliminate leaks in the welded seams and resulting loss of static pressure, the heat exchanger tubes are inserted into the tubing sheets using a slip fit. Loctite 635 retaining compound is applied to the outer diameter of the tubes. The tubes are then expanded into the tube sheet. The new process is faster than brazing and does not require specialized labor.

In a steel roller conveyor application, Loctite 638 retaining compound seals the bearing housing and eliminates corrosion from water intrusion around the housing. Since the adhesive replaced welding, it saves labor by eliminating the need to grind the weld seam on every bearing housing. Production speed could be further improved by automating the process of dispensing the adhesive and assembling the parts.

A bonded slip fit replaces the press fit in a gear box. The new bonded design meant that tolerances for the parts could be relaxed, lowering the overall cost of the assembly while doubling torque performance.