Light emitting diodes (LEDs) offer many potential benefits over traditional light-curing equipment. LEDs last longer, cost less to operate, generate less heat, and can be used in more flexible configurations.

Until recently, LEDs have not had sufficient power to cure adhesives in manufacturing operations. However, thanks to new technology, it's now possible to produce LEDs with enough output to meet this challenge.

Typical light sources use electricity to heat a filament or excite materials into a plasma state, thereby generating light. LEDs generate light when electric current runs through a semiconductor. Traditional light sources have bulky, expensive bulbs; LEDs are small and inexpensive. Compared with traditional light sources, LEDs generate less heat and require less energy to produce equivalent amounts of light. Finally, whereas traditional light sources cost thousands of dollars plus associated bulb replacement costs, LEDs are available for less than $1,000, with no bulb replacement required.

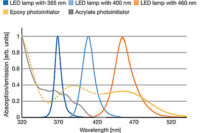

LEDs produce light in a very narrow range of wavelengths compared with other light sources. While the dental industry has used LEDs for years to cure composites, these devices typically emit light with a wavelength of 450 to 470 nanometers, too high for typical assembly adhesives. The latest LEDs produce light at a wavelength of approximately 405 nanometers, which is appropriate for a wide range of assembly adhesives.

The narrow spectral distribution range of LED light sources eliminates output in the infrared range, so the potential for damage to heat-sensitive substrates is minimized. Because LEDs do not require a warm-up or cool-down period, they can be turned on only when they are needed, further increasing their energy-efficiency. Their low power consumption allows them to be built into small handheld units with irradiance levels of more than 1 watt per square centimeter. Finally, the operating lifetime of an LED is measured in tens of thousands of hours, much longer than the lifespan of alternative light sources.

Many LED-based curing systems are designed to be used as handheld units, but some are suitable for use in automated processes. These point sources won't effectively irradiate a large area. However, they can easily be mounted over a conveyor to irradiate parts as they pass beneath.

Adhesive Technology

LEDs with output in the 405 nanometer range deliver excellent performance with adhesives that cure when exposed to visible light-light with a wavelength above 400 nanometers. Adhesives that cure in visible light offer two key benefits to assemblers. They can be used on substrates that block ultraviolet (UV) light, including many plastics and glass. And, they tend to have better depth of cure than UV adhesives.

Unfortunately, the farther light absorbance extends into the visible region (450 nanometers and beyond), the more likely the adhesive will have an undesirable color. Adhesives that absorb light in the lower visible light range allow assemblers to reap all the benefits of visible-light curing with water-clear formulations. The performance and processing advantages of these adhesives could not be fully exploited until LEDs became available with output as low as 405 nanometers.

In addition to spectral output, the irradiance of an LED is critical to its curing performance. Irradiance measures the rate at which an LED delivers light energy to an area. It's typically expressed in units such as watts per square centimeter. The irradiance of a light source has a dramatic effect on its adhesive curing properties, such as depth of cure and the time to reach a tack-free surface. While the right adhesive formulation can mitigate some cure concerns, high irradiance or output is required to ensure a complete, tack-free cure.

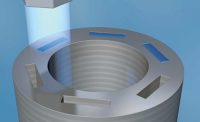

LEDs always generate heat as they operate. With typical LEDs, as heat increases, light output drops, making it difficult to achieve the high output levels required for many adhesive curing applications. To solve this problem, the newest LED light source has an internal cooling system that allows the LED to operate at power levels far higher than other LEDs without a drop in output. The device is handheld, battery-operated and highly portable. This portability permits easy positioning of the light source in confined areas and expands its viability beyond typical applications. The device cures adhesives in seconds to yield hard, tack-free adhesives that bond tenaciously to a wide variety of materials.

Adhesives that cure at the low end of the visible light spectrum do not present any special problems with handling and dispensing. The irradiance levels needed to harden these adhesives are high enough that energy from ambient lighting will not cause the adhesives to cure rapidly enough to be a concern. If open bottles of adhesive are left under ambient lights for many hours, some problems may develop, but this is easily avoided in production.

Future Developments

The development of high-irradiance LEDs has opened the door to widespread use of LEDs for curing adhesives in assembly applications. By lowering the investment and operating costs associated with light-curing technology, LED systems are allowing more assemblers to take advantage of adhesives that cure in visible light.

The economic advantages of LED technology will continue to drive innovation in this area as light-curing equipment suppliers find ways to satisfy industrial needs. On the horizon are LED systems that can cure larger areas. Increased irradiance may also allow LED systems to cure a broader range of adhesives faster. While adhesive formulators have already made great strides in producing adhesives that cure rapidly with LED systems, the range of adhesives will continue to expand.