An understanding of materials is crucial when selecting a dispensing system.

An understanding of the properties of the fluid being used in an assembly is crucial, no matter how complex the dispensing system.

However, before making a purchase decision, it’s important to understand the properties of the material you are dispensing. Ultimately, it’s the fluid going into or onto an assembly that determines the system you need to install. The most sophisticated equipment in the world will do little good if it isn’t appropriate to your particular situation.

Materials like anaerobic resins and cyanoacrylate adhesives need to be shielded from metal parts to prevent premature curing.

Dispensing Principles

To begin with, there are five principles relevant to any dispensing application.The first, that air is compressible, but fluid is not, explains why a fluid can be dispensed at all. If fluids were compressible, accurate dispensing could never be achieved. This principle also explains why there is a delay in fluid flow when using compressed air and a simple air line attached to a syringe-the air must first be compressed before it can impact the fluid. In addition, as the fluid in a syringe is used and the fluid level drops, the air volume increases, resulting in an additional delay or smaller shot size.

The second principle of dispensing dynamics holds that the amount of fluid dispensed is related to pressure, time and needle size. This second principle applies to any dispensing device, including syringes and valves, and explains why changing any one of these three parameters will alter the dispensing result.

The third principle of dispensing is that a dispensed shot is equal to half the volume of a sphere: Volume = D³ x 0.5236 / 2. This principle can be used to calculate reservoir supply and fluid usage.

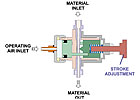

The fourth principle of dispensing is that for an accurate and repeatable shot always use a valve, as opposed to a syringe. A valve has no variable air space and will therefore provide accurate and constantly repeatable shots.

The fifth principle, which follows naturally from the fourth, is simply that fluid and viscosity will determine the valve to be used. Understanding this principle will ensure questions are raised about the fluid before selecting a suitable valve.

In terms of specific fluids, materials can be classified as being one of two types, a liquid or a paste. Included within these two categories are adhesives, epoxies and resins, silicones, solvents and volatiles, sealants, marking inks, solder cream or pastes, solder masks and various lubricants from oil to thick grease.

One of the defining characteristics of any of these fluids is its “thickness,” or viscosity, usually stated in centipoise (cps), or in millipascals, with 1 millipascal equal to 1 centipoise. Fluids with high centipoise are thick and have no self-leveling capabilities, while fluids with low centipoise are thin and possess self-leveling properties. Because viscosity may change over time or with a change of temperature, measures must be taken to either defer or compensate for these kinds of variations. The following examples provide a reference of viscosity:

- Water: 1.002 cps

- Vegetable oil: 80 cps

- Engine oil: 1,000 cps

- Solder mask: 6,000 cps

- Ketchup: 30,000 cps

- Mustard: 200,000 cps

- Pastes: 1,000,000 cps

Pinch-tube valves are often used with cyanoacrylate adhesives because the polymer tube portion (in purple) shields the valve’s metal parts from the material being dispensed.

Cyanoacrylates

In addition to viscosity, engineers need to be aware of the special handling required by some fluids due to their particular chemistries. Cyanoacrylates, for example, are “instant” adhesives that appear as clear liquids with viscosities from 3 cps to 2,000 cps and include three principal chemical components: methyl, ethyl and butyl. They work by polymerizing after coming in contact with humidity, a reaction that starts at the surface and then moves in toward the center of the deposit.To ensure good adhesion, or a good bond, between two substrates, the thickness of the cyanoacrylate must be thin. This is because “blooming”-a white dusty marking on the surface near the adhesive-may occur when a large amount of cyanoacrylate remains in liquid form, as some of the material vaporizes and then reacts with humidity in the atmosphere.

Cyanoacrylates are generally shipped in 20-gram, 50-gram or 500-gram high-density polyethylene bottles. Gel cyanoacrylate is usually packed in tubes, because of its viscosity. Storing the bottles in a refrigerated environment will eliminate moisture and extend the life of the fluid.

Cyanoacrylates can be dispensed directly from a bottle using a peristaltic pump or by placing the entire bottle in a pressurized glass reservoir and running a fluid line to a valve or pinch pen. Operators can use a Teflon pinch pen for manual control, or a Teflon pinch tube or diaphragm valve for timed control. The choice depends on the material packaging and how it is to be dispensed.

Cyanoacrylates can also be dispensed using polypropylene cartridges and compressed air, in which case it is important to include a filter trap in the air line to ensure the material can’t back up into the compressor. Cartridges with pistons are not recommended because the pistons will inevitably leave a thin layer on the inner wall of the syringe barrel, causing the material to quickly cure, or “kick.” Because cyanoacrylates react with moisture and most metals, it is important to use dry compressed air or nitrogen and ensure that that all wetted parts are nonmetallic.

A pressurized glass reservoir can be used to dispense thinner materials. In this system, the controller is regulating both the reservoir pressure and controlling shot size and frequency.

Anaerobic Resins

Anaerobic resins are acrylic-based and can be formulated to provide a range of different adhesive strengths. The most common dispensing application for anaerobic resin is onto screw assemblies, where they are used as an alternative to mechanical lock-washers. Anaerobic resins can also be used in cylinder assemblies and to create liquid gaskets.Two conditions are necessary for the polymerization of an anaerobic resin into a hard plastic: the absence of air and the presence of metal ions. Stainless steel and aluminum are low in free ions, so cure times are long, but the bonds are strong ones. Copper and brass contain an abundance of free metal ions, promoting rapid polymerization, but the bonds that result are less robust.

Temperature also influences curing time. For example, an anaerobic resin may require 24 hours to cure at room temperature, but only 20 minutes cure time at 80 C. Higher temperatures also promote adhesion.

Because the viscosity of anaerobic resins is temperature sensitive, volumetric control is often required to dispense them in precise quantities. In general, viscosity will increase dramatically between 15 C and 25 C, and then level off after that. Some manufacturers dispense their anaerobic resins at 30 C to maintain uniform viscosity.

Low viscosity anaerobic fluids are usually packaged in 50-gram and 250-gram bottles, while higher viscosity products are packaged in tubes or cartridges. Bottles should be made of low-density polyethylene, so that air can pass through to the resin to prevent polymerization. Anaerobic fluids are generally shipped in bottles that are only partially filled. This allows for movement of the contents, some of which might otherwise cure.

Larger 1-kilogram bottles are available for high production requirements. However, while anaerobic resins have a shelf life of up to a year when refrigerated, they can only be stored for 2 or 3 months at room temperature. Prior to use, refrigerated resins should be brought up to ambient temperature to provide a normal working viscosity.

Flexible, Teflon-lined tips can be used to dispense anaerobic resins at lower temperatures and in applications where dispensing is continuous. Polyethylene pistons and syringes can be used to prevent dripping.

When using a metal reservoir, be sure to incorporate a liner to prevent premature curing. Also, anaerobic resins must never be used with any valve that includes metal wetted parts. A common setup is to use a 250-gram bottle placed directly inside a pressurized reservoir to feed the material directly to a pinch-tube pen or nonmetal valve.

UV Resins

UV fluids represent a diverse range of products. In fact, they are not so much a family of products as a system of cure. UV fluids perform three principal functions: bonding, coating and sealing. They provide excellent adhesion, but are costly compared to many other materials and require the purchase of curing equipment. For many UV resins, polymerization can only be achieved through exposure to UV light.The necessary wavelength to cure a UV resin is 365 nanometers, generally obtained with a high-density mercury bulb. The power of a UV ray is calculated in milliwatts per square centimeter. For adequate polymerization, a minimum strength of 50 milliwatts is necessary.

Packaging is generally in the form of 50-gram, 250-gram or 1-kilogram bottles. High-viscosity fluids are packaged in cartridges. Storage life is between 6 months and a year at room temperature.

Generally, the methods used to dispense UV fluids are similar to those used to dispense anaerobic resins. However, a few changes are required. For example, amber or black barrels must be used with UV resins to protect them from ambient light, and sunlight in particular. Also, reservoirs and the wetted parts of any valve must be made of stainless steel to avoid the contamination that can be caused by other materials.

Silicones

Silicone is a high-viscosity material used for bonding, sealing and coating. Because silicone is an anti-adhesion material, paint and other coatings will not stick to it. Some silicones will corrode electronic circuit boards, so special formulations have to be used in those kinds of applications. In addition to being oil and water resistant, silicone’s elasticity makes it highly resistant to vibration.With silicones, curing is not the result of polymerization, but of vulcanization. In this process the naturally occurring humidity in the atmosphere releases fixing acids that are incorporated into the material. These acids, in turn, cause the silicone to rubberize. Obviously, when storing silicone it is important to protect it from humidity.

One of the principle components in most silicones is acetic acid, which evaporates when the silicone is dispensed, exposing it to the surrounding air and initiating the vulcanization reaction. Curing times are generally around 12 hours, but can vary depending on the formulation and the thickness of the material.

Silicones are available in tubes, cartridges and plastic pails. Because vulcanization begins when the silicone comes in contact with air, it is vital to maintain an airtight seal throughout the dispensing system. If there is going to be an extended pause between dispensing cycles, the dispensing needle or nozzle should be “parked” in silicone oil, or a small amount of silicone oil should be placed on the tip.

When dispensing 300-millileter cartridges, assemblers should use a cartridge retainer to reinforce the sides. For tubes, a tube gun, caulking gun or Autotube dispense system is a good solution. To dispense from a 1-gallon or 5-gallon pail, an extruder system, employing a “follower plate” inside the pail, can be used to pump the material to the valve. A flow regulator needs to be used to help smooth out the fluid pulses that can result when pumping material from an extruder system.

Grease

Despite the many types of grease on the market, they can all be separated into two categories: grease with and without fillers. In either case, assemblers can use the same basic packaging and dispensing methods used with silicone.Some grease types will separate during storage and need to be agitated prior to use. When doing so, however, it is important to prevent air bubbles from forming in the material if the dispensing application requires a high degree of shot consistency.

When using greases with fillers, it may be necessary to employ a heavy-duty valve to ensure the filler doesn’t degrade or destroy the valve’s seals. Also, tip size should be four times greater than the size of the filler particulate to prevent blockages.

Grease is normally dispensed using an extruder pump, because the pressure reservoir approach is not practicable with a material of such high viscosity. The most common nozzle size used with grease products is 1/4 inch. Because grease can often be quite expensive, it may make sense to employ a controller-as opposed to relying on an operator to control shot sizes-to save on material costs.

Varnishes and Solvents

In addition to thinning paint, solvents can be used to bond plastic parts. Varnish serves as a protective coating and can also be used to lock plastic screws, seal holes and fix wires.Although these two classes of fluids are used for different purposes, their dispensing requirements are much the same. For example, they are both generally packaged in metal cans, although varnish is also available in tubes. When dispensing, all fittings and connections need to be well sealed to prevent evaporation, and all wetted plastic parts should be made of polyethylene and polypropylene to resist degradation. Even then, O-rings and seals will require regular replacement.

When using solvents, a Viton adapter O-ring is more resistant than one made from Buna. When employing a reservoir, always include a liquid filter-trap and a safety clip.

Note that when dispensing with a reservoir, the air inside will absorb the solvent to the extent of saturation. Once saturated, the atmosphere in the reservoir will remain stable. This is why a half-full can of varnish will remain liquid as long as it remains sealed.

With this in mind, the reservoir must always be kept under pressure and not depressurized at night or after use. If this procedure is not carried out the fresh air will again become saturated, depleting the available liquid solvent.