White Papers

Click here to browse informative reports from our advertisers on new assembly technologies.

ARTICLES

Sponsored Content

Track Busway Offers Customizable, Flexible, and Scalable Power Distribution for Harsh Environments

March 1, 2024

advertisement

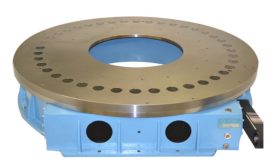

Advantages of Precision Link Indexing Conveyors for Medical Device Manufacturing

June 6, 2023

advertisement

Use an engineered approach to tailor a perfect standard gas spring for your design

June 6, 2023

advertisement

When to Automate: A Closer Look at the Most Frequent Automation Applications

December 5, 2022

advertisement

LFA HSP Series - When Precision meets High Speed Performance

December 4, 2022

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing