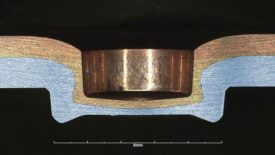

Assembly Presses

Articles about pneumatic, hydraulic and servo-electric assembly presses.

ARTICLES

Automotive Industry

New Automotive Press Line Will Be Accessible for Disabled Workers

The line has lower HMI's and extra room for people in wheelchairs.

April 25, 2024

Never miss the latest news and trends driving the manufacturing industry

Stay in the know on the latest assembly trends.

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing