Screwdriving and Riveting Assembly

Articles about threaded and nonthreaded fasteners and the equipment for installing them.

ARTICLES

Cordless Power Tools Market Set for Growth

The market is projected to expand by $4.43 billion through 2027, driven by battery innovation and DIY trends.

April 2, 2024

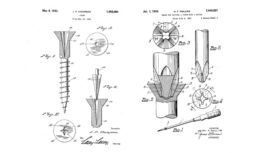

Threaded Fasteners

Course to Teach Fundamentals of Threaded Fastener and Joint Design

Participants can earn up to 24 professional development hours with this course.

March 1, 2024

EVENTS

Featured Event Industry

5/1/24 to 5/2/24

Music City Center

201 Rep. John Lewis Way S

Nashville, TN

United States

The ASSEMBLY Show South

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest assembly trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

ASSEMBLY is thrilled to return to the Music City Center in Nashville, TN for The ASSEMBLY Show SOUTH on May 1-2, 2024. This is a booming time for manufacturing and the U.S. South is right in the heart of the action. According to ASSEMBLY’s most recent annual capital spending survey, the South is projected to account for 31 percent of total spending this year, marking the fifth straight year this region has accounted for at least 30 percent of capital spending in the U.S.

ASSEMBLY is thrilled to return to the Music City Center in Nashville, TN for The ASSEMBLY Show SOUTH on May 1-2, 2024. This is a booming time for manufacturing and the U.S. South is right in the heart of the action. According to ASSEMBLY’s most recent annual capital spending survey, the South is projected to account for 31 percent of total spending this year, marking the fifth straight year this region has accounted for at least 30 percent of capital spending in the U.S.