Eaton Corp. produces more than 1 million engine valves per day for nearly every automaker and engine manufacturer in the world. One of the company’s largest manufacturing facilities, located in Kearney, NE, supplies highly engineered valves that increase fuel economy, improve efficiency and boost performance. With the exception of summer and winter maintenance periods, the plant runs its just-in-time production 24-7.

|

|

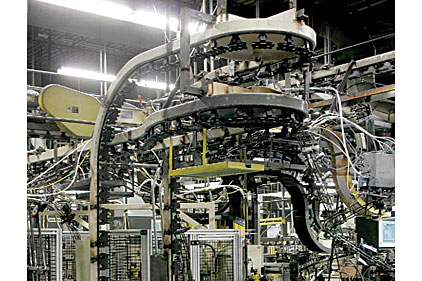

Conveyor track makes extreme turns to

integrate with multiple operations at Eaton’s

plant in Kearney, NE. Photo courtesy Richards-

Wilcox Inc.

|

The heart of the manufacturing operation is an overhead monorail conveyor system consisting of six lines, each of which features more than 2,000 feet of track and chain (with 6-inch pitch). Made by Richards-Wilcox Inc., the conveyor system incorporates several curves and loops in a limited amount of space.

After being extruded from steel slugs, the valves are put into a bin at the start of the conveyor and moved along the track that is integrated with machinery used for as many as 16 automated processes. These include washing, forming, grinding and sanding. Workers do not touch the valves again until they are packed, skidded and moved for distribution.

Joe Bash, a plant manager for Eaton, oversees line layout and production. He has experimented with and implemented various track designs to make the most efficient use of floor space.

Prior to installing the conveyor system, Eaton used a material handling system that required several operators to load batch lines. By contrast, the conveyor system requires just one operator to tend six machines, significantly cutting Eaton’s labor costs.

The conveyor system also provides two other benefits. Changeover times have been significantly reduced, from 8 hours minimum to 1.5 hours maximum. Also, the conveyor system’s split-line configuration enables Eaton to do low production runs at maximum efficiency, while still providing just-in-time manufacturing.

For more information on overhead conveyer systems, call 888-852-1020 or visit www.rwconveyor.com.