Strange as it may sound, LED digital billboards and displays have much in common with icebergs. All of them are large, eye-catching and often serve as landmarks for countless passersby.

| Jump to: |

New Jersey residents understand this analogy—especially those that either drive by or visit MetLife Stadium on Sundays from August to December. Each week the stadium showcases an integrated video, scoring and advertising digital display system during National Football League games hosted by either the New York Jets or New York Giants.

Daktronics Inc. designed and installed this extensive system prior to the 2010 season. It includes four, large video displays inside the seating bowl, as well as 20 vertical, four marquee and several ticket-window displays outside the seating bowl.

Fans at MetLife and many other stadiums rely on these displays for constant information and entertainment. But, like an iceberg, there’s much more to each digital display (and billboard) than what is clearly visible.

Within each one are intricate LED modules that present a daily assembly challenge for Daktronics and other leading manufacturers, such as Watchfire Digital Outdoor and the Young Electric Sign Co. To meet this challenge, all three companies rely on assemblers skilled in using the latest tools and automated equipment.

Industry Leaders

Daktronics has built and installed hundreds of thousands of LED digital billboards and displays in more than 100 countries. The past decade has been great for the company. It has become publicly traded on NASDAQ and opened a 140,000-square-foot facility in Sioux Falls, SD, just 50 miles from its corporate headquarters in Brookings, SD.

Daktronics has built and installed hundreds of thousands of LED digital billboards and displays in more than 100 countries. |

Manufacturing is performed at both South Dakota facilities, as well as at plants in Redwood Falls, MN; Victor, NY; and Shanghai, China. Gary Daly, plant manager for Daktronics in Sioux Falls, says the company operates nearly 1 million square feet of manufacturing space at the four plants.

Daktronics has about 2,700 employees, with more than 1,000 devoted to assembly and manufacturing. Its digital billboards are used in several markets, including commercial advertising (on- and off-premise), sports (pro, college and high school), government, transportation and entertainment venues.

Watchfire Digital Outdoor has been manufacturing LED billboards since 1996. “Our company was founded in 1932 as a manufacturer of mechanical sign flashers that created the chasing or scintillating effect on theater marquees of the day,” says Darrin Friskney, vice president of Watchfire. “Later we developed the time and temperature displays that so many local banks featured on their primary signage.”

In the 1970s, the company was at the forefront of developing multi-message incandescent signs. For the last 20 years, Watchfire has focused on digital signage as LEDs became viable for use outdoors. Currently, it has more than 45,000 outdoor LED in daily operation throughout North America.

The company’s headquarters and manufacturing facility is located in Danville, IL. More than 300 people work there, up from 250 in early 2012. Yearly production volume varies, but Friskney says the plant’s recent 110,000-square-foot expansion can handle any increased capacity for the foreseeable future. To date, the company has done business with 250 billboard operators in the United States, Canada, Central America, South America and Africa.

Another company with a long history is the Young Electric Sign Co. or YESCO. Founded by Thomas Young in 1920, it has been run by his family for three generations. The company operates four manufacturing facilities encompassing 840,000 square feet.

YESCO has plants in Salt Lake City, Logan, UT, Las Vegas and Phoenix. The company also has 43 service and sales offices throughout North America. It employs 1,500 people.

“We provide signs and service to at least 70 industries,” says Jeff Young, senior vice president and chief marketing officer for YESCO in Salt Lake City. “But our customer base is weighted toward retail, hotels, recreation, government and education.”

Assembly Methods

A digital billboard or display consists of two sections that are assembled separately but simultaneously: an LED electronic module and a cabinet. YESCO begins its electronic assembly by populating PCBs with integrated circuits, LED lights, capacitors, resistors and other components purchased from domestic and foreign vendors. After the PCBs are assembled into a sealed module, it undergoes environmental and quality-control testing.

“Usually, our cabinetry is constructed from modular parts that are punched out of aluminum sheets,” says Young. “This manufacturing style allows us to easily accommodate [requests for] unusual shapes and installation conditions.”

Once the LED module and cabinet are finished, they are brought to a separate line and fastened together to create a billboard. Test patterns are then run for 48 hours under a variety of operating parameters to ensure the billboard is fully functioning. After this burn-in process, workers calibrate the billboard for consistent luminous intensity and color temperature. Finally, it is shrink-wrapped and shipped.

Young says about 90 percent of PCB assembly is automated because of the quantity and small size of the parts. The company uses both surface-mount and through-hole processes. Equipment is made by Nordson Asymtek, Universal Instruments and Speedline Electrovert.

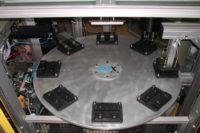

Daktronics builds every LED electronic module to IPC 610 Class 2 standards or better. To maintain this level of quality on the assembly line, workers use control charts, statistical techniques, data logs and automated equipment. Module assembly is mostly automated.

All modules are tested with highly sensitive cameras and a Daktronics Intelligent Device Management (DIDM) system that validates proper function, color, placement and orientation. DIDM also monitors critical specs and makes adjustments as necessary to ensure a consistent, high-quality product. At each step in the build process, the system captures and analyzes data workers can use for continuous improvement.

The company makes its cabinets out of dense, corrosion-resistant aluminum components that can withstand rain, snow and extreme heat for at least 10 years. Fabrication is done in the metal shop, where computer-controlled equipment forms and processes sheet metal into components.

“Operators use production gauging equipment to verify that components meet engineering requirements and ensure daily consistency,” notes Daly. “We develop standard methods, such as setup procedures and control plans, to process a specific component.”

Hand tools and cranes are used to assemble the module and cabinet. After final assembly, the billboard is tested to specific engineering and customer requirements to confirm functionality. In addition, some products are water tested to insure they meet water-intrusion standards.

“We recently added a vacuum lift station into the final assembly process,” says Daly. “This enables us to handle larger aluminum sheets and increase efficiency.”

Friskney says Watchfire performs quality testing on module components at each step of the assembly process and on the final LED module. Components include PCBs, resistors, chips and high-quality LEDs. The final module is immersed underwater for 180 consecutive days, placed in salt spray for 60 consecutive days and exposed to temperatures as low as -40 F.

Each module has just two connection points. To ensure durability and performance in all climates, it is fully encapsulated in a bed of all-weather silicone gel.

The cabinet is made of aluminum extrusion that is measured and cut into sections by automated equipment. These sections feature precision-mitered corners and 30 percent gloss-black polyurethane finishes. They are welded into a lightweight but durable cabinet, says Friskney.

After Watchfire assemblers manually join the module and cabinet with stainless steel fasteners, the billboard is quality tested. Finally, the billboard is calibrated for color and brightness.

“We use single-bin LEDs, meaning all of them start off with the same color and brightness,” says Friskney. “Factory calibration and three LEDs per pixel ensure excellent image quality and reliability for many years in the field.”

All Watchfire LED billboards run on Ignite graphics software, which enables the sign owner to quickly create text, graphics, animation and video. The software also lets the owner instantly preview and schedule messages from his computer so he knows what’s being displayed at all times.

LED by Innovation

Friskney says the growing popularity of LEDs has lowered their price and resulted in improved performance. They are now widely used in automobiles and by architects, as well as in various consumer products and for general illumination.

“Without question, the digital signage industry is in a strong growth mode,” says Friskney. “As businesses and billboard operators learn about the advantages of LED boards, we expect accelerated growth for many years to come.”

Young says that there has been an evolution in LED technology, and that it is beneficial. Initially LED displays used discrete red, green and blue diodes. Today the industry is moving toward three-in-one surface-mount LEDs, which can be placed closer together to produce higher-resolution displays.

“This shift has required us to develop the competency and make the necessary capital investment to produce both technologies,” says Young. “It’s a challenge to make sure all the [billboard] parts and pieces are available and in sync with [customer] demand. We’ve had to organize ourselves better.”

In all of its processes, Daktronics implements lean manufacturing to identify and eliminate waste wherever possible. Daly says the company has systems that track performance and capture data, enabling Daktronics to implement continuous improvement and always meet promised production deadlines.

“Scheduling various-sized billboards and custom displays on our production lines can be challenging and tricky at times because they all affect our takt time,” says Daly. “But, our business has proven to have some seasonality to it. We adapt to each unique situation.”

In 2008, Daktronics opened an in-house product reliability lab that uses the latest technology to perform environmental testing, including extreme temperatures, humidity and storms. Daly says the lab provides important data that helps the company design and manufacture more reliable and efficient billboards. For example, Daktronics has reduced the power consumption of one billboard model by more than 50 percent in the last 18 months.

“Because of the medium’s immediacy, users can speak to their audience with changing messages throughout the day and night, and national advertisers can deploy national ad campaigns almost instantaneously,” says Young. “Best of all, most digital billboards used in the United States are built in the United States.”