Science writer John Wilford once observed that his articles had to focus on one of these story lines to earn their way into print: “big bang, big bucks, big screwup, or big comeback—and with the Hubble Space Telescope you’ve got them all.” He was right. Since launching into orbit almost 30 years ago, Hubble has gone from the humiliation of “techno turkey” to high-risk recovery to recognition as one of history’s most prolific scientific explorers.

Before setting out on its decades-long journey, Hubble was touted as the greatest advance in astronomy since 1610, when Galileo peered up at Jupiter through a telescope he invented. Four centuries later, astronomers hoped that Hubble—then the most complex and costliest satellite ever dispatched into space—would enable them to home in on the big bang. The product of 12 years of design, testing and construction, the gleaming aluminum cylinder would break down barriers of space and time to obtain crystalline images of celestial objects and events never seen or even imagined.

“Hubble will probe the secrets of creation,” promised Lennard Fisk, chief scientist for the National Aeronautics and Space Administration (NASA).

Instead, a shaping error in Hubble’s primary mirror had gone undetected for 10 years until fuzzy photos from its wide-field planetary camera (WFPC) unscrolled at Goddard Space Flight Center in Greenbelt, MD. Traced to a tiny paint chip and three faucet washers, the distorted images forced cancellation of Hubble’s highest priority searches into the deepest precincts of the universe. Hubble’s high-flying image plunged into free fall. Congress was outraged, the media unforgiving, and a disenchanted public demanded to know whom to hold accountable for the fiasco. “Astronomical Error,” “Mission Impossible” and “Space Telescope Can’t See Straight” headlined newscasts and front-page newspaper articles. Hubble became the butt of late-night TV jokesters and a metaphor for engineering ineptitude.

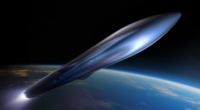

Of course, failure wasn’t on the agenda, April 24, 1990, at 8:33 a.m. when the space shuttle Discovery lifted off from Cape Canaveral and rode plumes of steam and fire through a bright Florida sky for the 381-mile trip into low-Earth orbit. The next afternoon, astronaut Steven Hawley manipulated controls on the shuttle’s robotic arm and gently lifted the $2-billion bird from its cargo bay nest. The world’s first spaceborne observatory flew free.

Forty-three feet long and 14 feet wide, Hubble circumnavigated the Earth 15 times a day at 1,700 mph. The size of a railroad tank car, “it looked like an elongated refugee from an Erector set,” according to one writer. A pair of wing-like arrays, 23.3 feet long and 8.6 feet wide, were covered by almost 100,000 silicon solar cells, each as small as a postage stamp. They generated all the electricity needed to power the spacecraft.

Cotton Ball Coronas

Hubble’s eye, a 10-foot-wide aluminum aperture, blinked open on May 20, bringing light from the edge of the universe to the telescope’s finely polished primary mirror. It was time to take some pictures.

Ninety-four inches in diameter, the concave mirror funneled light to a convex secondary mirror mounted 16 feet above. The 12-inch mirror redirected the concentrated light down through the center of a 2-foot hole in the primary mirror to five refrigerator-sized scientific instruments. Two digital cameras, two spectrographs and a high-speed photometer would enable Hubble to observe visible, ultraviolet and infrared light.

The $68 million WFPC was scheduled for 50 percent of telescope time. Mission success depended on its ability to focus on primordial galaxies and stars and send pictures with 10 times the clarity of mountaintop observatories. Instead, what appeared on control center monitors were hazy objects with hairy tendrils enshrouded in cotton ball coronas.

Controllers spent weeks trying to bring the images into focus, but nothing worked. That’s because the primary mirror was afflicted with a spherical aberration that dispersed light over multiple focal points rather than to a targeted spot. Hubble’s light-gathering capability topped out at a measly 15 percent, not the 85 percent for which it was intended. Similar problems plagued the faint object camera, the faint object spectrograph and the infrared spectrograph.

The mirror’s bowl-like design required perfectly smooth contours to accurately collect and concentrate light, but its outer edge was shaped too flat by 0.000004 inch, one-fiftieth the width of a human hair.

NASA canceled WFPC observations of faint, distant objects, but Hubble could still perform scientific explorations inaccessible to Earth-bound observatories. To prove that the telescope’s debilitated cameras could operate effectively, NASA released colorized, computer-enhanced images that brought clarity to the distorted originals. These included the first pictures of Charon, the little moon orbiting Pluto; close-ups of Saturn and its rings; and shock waves from an exploded star.

“I am cheerfully depressed,” Riccardo Giacconi, director of the Space Telescope Science Institute, told reporters. “Hubble is finally doing first-class science, but for three years we won’t be able to do what we wanted to do.”

Perfectly Made, Perfectly Wrong

In 1977, NASA selected Perkin-Elmer Corp. as prime contractor for Hubble’s optical telescope assembly and fine guidance sensors. The firm brought four decades of know-how in building telescopes and optics for observatories and photoreconnaissance satellites. Perkin-Elmer’s reflective null corrector, an apparatus that could ferret out the slightest discrepancy in the curvatures of a telescope mirror, was a deciding factor in the space agency’s decision. So was the company’s deliberate underbid of $69.4 million on a cost-plus-fee contract that ballooned to $450 million ($2.6 billion in today’s dollars).

Ironically, Perkin-Elmer fabricated a primary mirror exceeding specifications by 20 percent. The surface was sculpted with a precision so painstakingly wrought that curvatures did not vary by more than 0.0000018 inch, a fraction of a wavelength of light. It was a perfectly made mirror made perfectly wrong.

Primary mirror production began at Corning Glass Works in upstate New York, where Perkin-Elmer subcontracted fabrication of a glass blank. Corning used an ultra-low expansion process to cast a hardened glass disc impervious to abrupt temperature changes from boiling hot to freezing cold. A 3,600-degree oven fired up a molten brew of silica and titanium oxide to form a pair of identical, 2-inch-thick glass faceplates fused to either side of a honeycombed lattice of 10-inch hexagonal slats. At 2,000 pounds, the circular sandwich came in 75 percent lighter than solid glass blanks of the same dimensions. Corning trucked the completed composite to Perkin-Elmer in December 1978 for shaping, polishing, measuring and coating.

A grinding machine with a diamond-tipped cutting tool engraved the mirror’s concave configuration and whittled off an inch from each faceplate. Shaping and polishing involved a mechanical arm orbiting over the mirror’s surface while applying a small abrasive pad in precision strokes over coarse-grained material. A succession of finer grained abrasives selectively trimmed mirror weight down to 1,825 pounds and into its final polished contours. Computers orchestrated loads, rotation rates and pressure, a first for a spacecraft mirror. Delicate hand polishing subsequently created an impeccably smooth finish.

Null and Void

Shaping and polishing procedures could last anywhere from 10 hours to 10 days and alternated with curvature accuracy tests run by the null corrector. The instrument would ensure that fabrication tolerances were meticulously observed. Shaped like a truncated beer keg, the million-dollar tool could detect, analyze and report surface blemishes down to millionths of an inch, far surpassing the precision of existing devices.

The null corrector was extremely sensitive to vibrations, so it was kept in a small enclosure attached to the ceiling. Following each shaping and polishing sequence, technicians shuttled the mirror over tracks and positioned it directly below the null corrector. Tests were conducted at night to avoid vibrations from 18-wheelers rumbling down a nearby highway. Speed bumps were removed from the company parking lot and air-conditioning switched off. None of the 28 tests conducted over 11 months detected signs of a spherical aberration, and all of them were wrong.

The measurements were wrong because the corrector’s two small mirrors and lens were wrongly assembled. The first mirror routed laser light to its twin, which reflected it down to the lens at the base of the appliance. The lens beamed this light onto the focal point of the primary mirror for curvature checks via interferograms. Evenly spaced waves denoted correct curvature. Uneven, broken waves signaled deformities.

The null corrector lens had to be set at a precise distance below the focal point of the mirror that reflected light onto it. To ensure accuracy, technicians scaled a metal measuring rod to that exact length and gave it a test. They trained a laser beam at a pinpoint hole in the center of a circular aluminum cap at the top of the rod. A direct hit through that hole and onto the reflective rod would rebound waves verifying accurate alignment between the mirror and the lens. Nonreflective black paint covered the cap to prevent the laser from shooting anywhere else except through the targeted hole, but a miniscule fleck had chipped off. Light bounced back from this exposed spot and transmitted false data that was accepted as accurate.

When the measuring rod was installed in the null corrector, the bracket to secure the lens in place came up short, indicating something wasn’t right. But under pressure to get the job over with, technicians brought the bracket and lens together with three flat washers, the same kind sold in hardware stores for a quarter. The lens setting was 1.3 millimeters askew, 10 times beyond specified boundaries. These assembly snafus were the direct cause of a permanently embedded spherical aberration in the primary mirror.

Perkin-Elmer cross-checked the accuracy of the null corrector using two smaller, less powerful versions of the instrument. Both displayed twisted, broken waves indicating a misshaped mirror. Management dismissed these findings, believing the less powerful instruments were not as good the latest version. Internal recommendations for follow-up tests were waved off. The company did not report any of this to NASA.

NASA did not insist on further testing, either, despite the refusal of the inspector assigned to Perkin-Elmer to sign off on the accuracy of the final product. A full system test with the primary and secondary mirrors installed in Hubble was deemed too expensive. The result: A flawed null corrector, assembled improperly and tested inadequately, churned out misleading data on a deformed mirror that went undetected until fuzzy images showed up on NASA screens 10 years later.

The primary mirror, washed in 2,400 gallons of deionized water and vacuum-coated in reflective aluminum and vaporized magnesium fluoride, arrived in 1984 at Lockheed in Silicon Valley. The prime contractor for the support systems module, Lockheed was charged with testing, installing and verifying systems to keep Hubble functioning. These included two solar arrays, two communications antennas, six nickel-hydrogen batteries, six gyroscopes, three fine guidance sensors, four reaction wheels, two computers, and a titanium ring girding the primary mirror. An aluminum skin enveloped the entire assembly and was wrapped in a thermal blanket of sixteen layers of Kapton insulation to reflect the sun’s heat. An outer shell of aluminized Teflon would provide protection from space debris. The telescope was ready to fly.

NASA delayed completion of the support systems module when the space shuttle Challenger exploded shortly after liftoff, Jan. 28, 1986. The 24,500-pound Hubble, with 400,000 parts, 15,000 miles of wiring and one spherical aberration, would not arrive at Kennedy Space Center until four years later.

Techno Triumph

On Dec. 4, 1993, space shuttle Endeavor eased within 30 feet of Hubble and unfurled a 50-foot robotic arm that maneuvered the observatory to a custom-built platform in the cargo bay. Millions watched live TV newscasts as spacewalkers free-floated around Hubble and moved about on a mobile platform to swap out intricate componentry and scientific instruments. Outfitted in bulky spacesuits with thick, heavy gloves, the four astronauts worked in pairs over five days to fix the telescope.

“Working on the Hubble while floating in space is like performing brain surgery upside down while blindfolded and wearing oven mitts,” quipped John Grunsfeld, a veteran of 58 hours of spacewalks, including the final Hubble servicing mission in 2009.

Before venturing into space, the astronauts spent 400 hours practicing their assignments in a 25-foot-deep pool at Johnson Space Center in Houston. Tucked into 350-pound spacesuits, they were lifted by an overhead crane into the pool, which simulated the weightlessness of space. Exact replicas of the equipment to be repaired sat at the bottom of the pool, including hundreds of bolts that would need to be unfastened to gain access to the modules housing the instruments. Once inside these cramped spaces, they were confronted by a maze of screws and plugs to detach and reinstall.

Engineers analyzed videos of each practice session. The observations enabled them to refine procedures and tools that would help the spacewalkers lift and exchange objects as small as shoeboxes and as big as pianos. A power ratchet tool, the workhorse device for the first three servicing missions, could vary speeds and torque while recording every turn in a computer. This input helped designers to craft more efficient tools and refine processes for future missions.

Jeffrey Hoffman and Story Musgrave were the first two astronauts to venture outside Hubble. Attached to foot restraints on the remote manipulator arm, the astronauts were firmly anchored as they went left, right and upside down around the telescope. While free-floating and tethered to the shuttle, Musgrave removed the cover where gyroscopes were situated. Hoffman installed small metal boxes called rate sensing units, each containing new gyroscopes to replace three that had worn out.

The following day, Tom Akers and Kathryn Thornton removed the two damaged solar arrays. One of them was bent at a 90-degree angle, and hundreds of the tiny solar panels had stripped away from each of them. Three days later, Hoffman and Musgrave ran into problems after installing new arrays. Latches unlocked, but the arrays would not deploy. Corrective commands from ground control failed to elicit any reactions, so the two astronauts hand-cranked a mechanism to deploy the arrays.

On day three, Musgrave and Hoffman unbolted the access door to the module where the WFPC was stored. They took out the WFPC and installed the WFPC-2, which was equipped with self-correcting optics that neutralized the spherical aberration on the primary mirror. On the following day Thornton and Akers opened aft shroud doors and installed the clunkily named Corrective Optics Space Telescope Axial Replacement (COSTAR), an enormous and complex optics package. COSTAR’s five coin-sized mirrors were perched on stalks staring at the faint object camera and two spectrographs. The mirrors intercepted and corrected aberrant beams from the primary mirror.

The $629-million service mission was a success. Soon, the telescope was providing awe-inspiring pictures of galaxies and stars formed when time and space began. Four more service calls over the following 16 years replenished Hubble with systems and instruments far exceeding the power and technology of the original equipment.

Hubble was projected for a 15-year ride but instead will log 10,950 days, almost 4 billion miles and 164,250 circuits of the Earth when it reaches its 30th anniversary April 24. NASA expects the observatory to function effectively for five more years after that, perhaps longer.