AUSTIN, TX—REE Automotive Ltd. is on a mission to revolutionize e-mobility from the ground up, changing the way that electric vehicles are designed and manufactured. The company specializes in EV platforms and modular components.

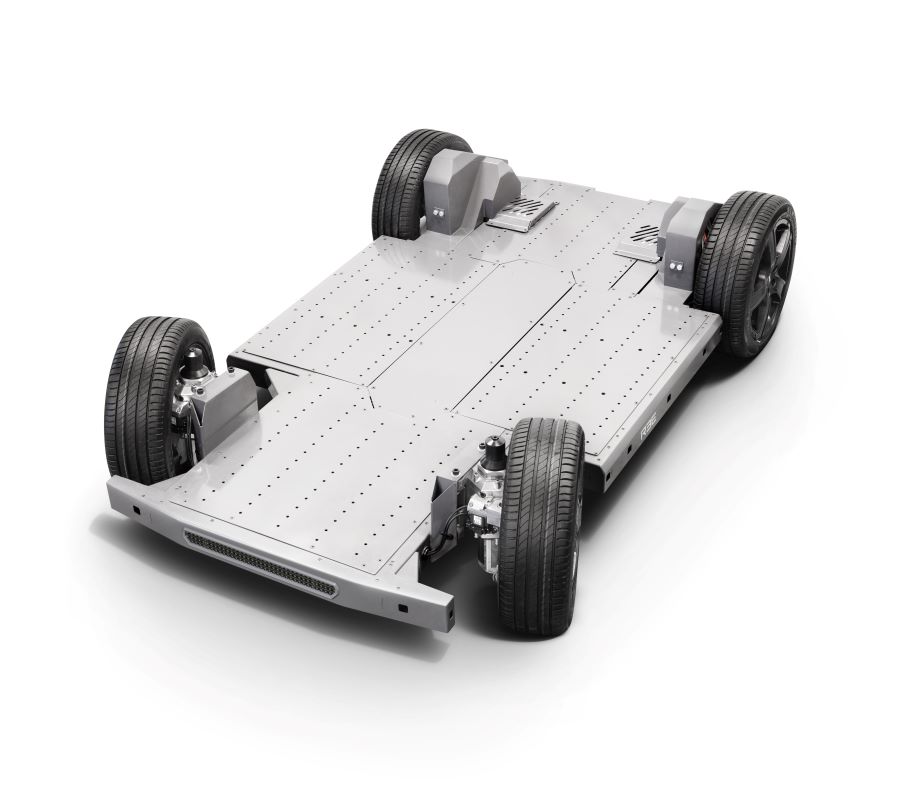

Its REEcorner technology packs traditional drive components, such as braking, control, power train, steering and suspension, into a single compact module between the chassis and the wheel, using x-by-wire technology for steering, driving and braking.

This innovation has enabled REE to develop a modular, fully-flat skateboard chassis with more room for passengers, cargo and batteries that it claims is highly adaptable to a variety of vehicle configurations and applications. EV platforms using REEcorners are agnostic to vehicle size and design, power source and driving mode, which enables new mobility players to get to market faster at a fraction of the cost.

REE’s production strategy relies on suppliers such as American Axle & Manufacturing Inc., which will be producing the 3-in-1 electric propulsion system. Those components and subassemblies will be attached to chassis at the company’s in-house integration centers. The first facility in Coventry, England, will open later this year, followed by a second operation in Texas next year.

“We’ve adopted a unique model for production intended to increase manufacturing efficiencies and accelerate our EV platforms and EV components’ time to market,” says Josh Tech, chief operating officer at REE. “Our modular production line concept is also highly automated, flexible and common to all integration centers regardless of location, meaning that we can scale up or down depending on future variants and demand.”

Tech, a former Tesla manufacturing executive, claims that REE will use a production strategy that provides “much greater flexibility and scalability than a traditional production line.” It will feature robotic assembly stations and end-of-line electrical test stations. Automated guided vehicles will move work-in-process between workstations for both automated and manual assembly tasks, while autonomous mobile robots will bring subassemblies to the line.

According to Tech, the modular production line will provide “countless advantages,” including the ability to validate all assembly cells quickly by testing and optimizing one cell and then implementing best practices across the others, which he claims will dramatically reduce the time needed to design and develop assembly lines.

“The modular production line is also highly automated and flexible, meaning that we can scale up or down depending on future variants and demand,” Tech points out. “In addition, assembly cells and production lines can be efficiently lifted and installed at future integration centers, as required, as we apply one global standard using the plug-and-play format.”