Comfort food can do more than just make a person feel good after a rough day. It can also be used, believe it or not, to help someone better understand a complex assembly technology. A s’more, for example, is not only the comfort food of choice around campfires—it’s also the perfect prop for illustrating how laser plastic welding (LPW) works.

“The s’more is a perfect analogy for LPW,” claims Jim Liddle, director of sales at LPKF Laser & Electronics. “The marshmallow and the chocolate are the two surfaces to be welded, and the heat that warms the marshmallow is the laser. As the marshmallow softens, its heat passes though and melts the chocolate, and the two become intermixed. The graham crackers are the upper fixture and bottom nest, so to speak, that apply pressure to completely fuse the two surfaces.”

Medical device manufacturers, like Billerica, MA-based Insulet Corp., are among the biggest users of LPW. For the past seven years, the company has been using LPKF’s InlineWeld 6600 system to weld the outer plastic housing to the chassis of the Omnipod device.

Part of the Omnipod System, this device is filled with insulin by the patient, who then adheres it to his arm or abdomen. The other part of the system is a wireless handheld Personal Diabetes Manager that programs the pod device with the patient’s personalized insulin-delivery instructions, wirelessly monitors the pod’s operation and includes a FreeStyle blood glucose meter.

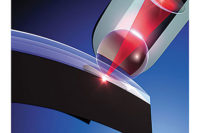

Insulet welds about 18 million Omnipods annually. Welding is done by a through-transmission process, where laser energy passes through a top component (the transmissive part) and is absorbed by the bottom component (the adsorptive part). The energy locally heats and melts the surfaces at the joint interface, and, with the application of a controlled clamp force, the parts are joined.

About 25 years ago, many engineers considered LPW to be the stuff of science fiction because thermoplastic polymers weren’t stable enough to conduct laser energy and enable welding. Today, laser welding of thermoplastic is commercially viable and fully embraced by medical device and equipment manufacturers of all sizes.

At the same time, LPW is also an evolving technology. The latest area of innovation is transparent welding, which uses a 2-micron laser (1,900 to 2,000 nanometers) that eliminates the need for additives to control melt when joining thermoplastics. Although use of this high-wavelength-laser method is still limited, it represents another way that companies can cost-effectively weld smaller, lighter and safer products.

Ways to Weld (Older and Newer)

Through-transmission infrared welding (TTIR) remains the predominant way that medical device companies weld their products. This process is typically done with a 1-micron diode laser having a wavelength between 808 and 1,064 nanometers. Cycle time ranges from a few milliseconds to 8 seconds, depending on material and part geometry. The laser is brought to the part using one of four techniques.

With contour, or spot, welding, the laser is focused to a single point, which is then directed along a preprogrammed path to create the weld. The ideal spot size for this kind of welding is 1 to 2 millimeters, although spot sizes can vary from 0.5 to 2.5 millimeters, depending on the application.

Contour welding’s main benefit is flexibility. Almost any welding path can be programmed into the welding machine, which can direct the beam using a moving stage, robotics or a system of mirrors and servomotors. After programs have been entered into the controller, changeovers from one assembly to another are possible with the push of a button.

Somewhat less flexible, but faster, is simultaneous line welding. With this process, laser light is directed along a straight line. Typical weld dimensions are 1 to 2 millimeters by 30 millimeters, with a cycle time of 1 to 2 seconds. Multiple lasers can be used to create square or rectangular contours. If necessary, optics can be used to create curved lines.

Similar to line welding is quasi-simultaneous or scanner welding. A set of servo-driven mirrors directs a single point of laser light along the weld path at a rate of 40 circuits per second.

On the plus side, this method offers cycle times faster than contour welding and comparable to that of simultaneous welding if the weld is small. Also, because servomotors are used to trace out weld geometries, a single laser head can be used for multiple welds.

Quasi-simultaneous welding’s one big negative is lack of flexibility. It is limited to flat or slightly contoured joints.

With mask welding—a proprietary technique developed by Leister Technologies—the laser line sweeps across the entire part, which has been masked so that only those portions left exposed will melt to create a weld. Manufacturers like that the method creates precise and complex weld patterns. Applications include sensors and microfluidic components in medical diagnostic devices with weld lines as narrow as 100 microns.

Although TTIR usually involves joining a clear part to an opaque one, two clear parts can be welded with the addition of Clearweld. Engineers simply apply this solvent-based coating—via liquid dispenser—onto the interface prior to welding. The coating absorbs light and acts as a focal point for the laser. Localized heating of the substrates occurs, resulting in an instant, optically clear joint with no particulates or very little to no visible color. It can also be custom formulated.

Transparent welding can be done using any of these techniques, even though it employs a 2-micron laser. The ideal wavelength is 1,940 nanometers.

“Being able to weld two clear parts has always been considered the holy grail of laser welding,” notes Andrew Geiger, manager of laser plastic welding at Leister. “The 2-micron laser allows this, but it works somewhat differently than a 1-micron laser. Instead of being absorbed only by polymers at the specific surface spot it touches, heat from the 2-micron laser affects everywhere it touches, from the surface to the exit point. The side effect of this is some excess heat gets absorbed in the part body and may cause thin areas to warp slightly.”

Geiger says that transparent welding is best for rigid parts, and those with a simple geometry or where aesthetics aren’t that important. He says the technology can be cost-effective for manufacturers that produce a high volume of small parts or a low volume of large parts.

According to Dax Hamilton, founder and president of Blackhawk Technology Group, transparent welding is excellent at bonding radial, lap and T-joints. Like TTIR, transparent welding quickly and reliably produces particulate-free and precise welds. The former capability is especially important to medical device manufacturers, as welds containing flash and other weld-process by-products are not acceptable.

Keeping parts stationary is a must for precise LPW. To ensure the creation of high-quality microfluidic components, LPKF’s PrecisionWeld 3000 transparent welding machine uses Differential Pressure Clamping Technology. The machine’s clamping tool applies internal pressure to create a homogenous pressure ratio and 100 percent contact between the lower and upper parts. With this technology, any burrs are reliably bridged over and positively locked.

Parts Aplenty

Many types of plastic parts for medical devices are laser welded. High-volume disposable components are common, such as filtering elements, blood-analysis-device parts and those with noncomplex housings. Others include diagnostic cartridges and products with plastic tubing (like catheters) or bags (for medicine or bodily fluids).

“Because of LPW’s ability to join components that are just a few millimeters in size, it is becoming the technology of choice to weld today’s increasingly advanced medical technologies,” says Tom Hoover, senior medical and business consumer electronics market manager for Branson at Emerson. “These include complex cardiac devices, wearables, microfluidics, devices for in-vitro diagnostic or drug delivery, sterile kits, implants, tissue-engineering, implantables, stent assemblies, lab-on-a-chip devices and optical scanning equipment.”

Emerson’s laser welding systems consist of a Branson Radiance 3G or 3I controller and one to four laser banks that, individually, deliver 125 watts of power. Each bank has five diode lasers, and each laser has 10 points that homogenize light before injecting it into the part during welding This process is known as Simultaneous Through-Transmission Infrared (STTIr) laser welding because it simultaneously illuminates the entire weld line with up to 500 points of laser light.

The 3G benchtop controller operates one or two laser banks and requires an external chiller for laser cooling. Model 3I is a free-standing controller that handles up to four laser banks and features an internal chiller. Both models interface with the company’s 2000X actuator for high-volume production.

Hoover says that because the 3G produces pristine welds, it is ideal for applications where aesthetics are a priority. It also offers precise weld depth control and the flexibility to weld a wide range of thermoplastics, 3D contours and delicate medical parts or those with embedded electronics.

Regardless of equipment supplier, fiber-coupled diode lasers are cooled with air or water. Air-cooled models, which are especially well suited for medical device manufacturing, come in 808-, 908- and 1,940-nanometer wavelengths, and provide up to 100 watts (1 micron) or 200 watts (2 microns) of power. The lasers offer high efficiency and are enclosed in a compact housing (19 rack mount) that easily integrates into production lines.

Dukane’s laser-welding workcell is capable of welding clear-to-clear plastics, and designed to weld medical device components of different sizes, including most common tube-to-port assemblies. The system’s 2-micron laser enables highly controlled melting through the thickness of optically clear parts, while LaserLinQ software harmonizes the action of a multiaxis servo gantry and a scan head to precisely control the laser beam movement. Alex Savitski, Ph.D., chief engineer for advanced technologies for Dukane, says that the software also lets users break complex weld patterns into separate geometric segments, and modify and assign different welding parameters to each segment. A built-in CCTV camera provides a live weld preview on the HMI screen and can monitor and record welding cycles for further analysis.

Healthcare technologies company Invetech uses the workcell to manufacture a consumable for its counterflow centrifuge (CFC) instrument. Researchers in the emerging cell therapy industry use the device to help develop new therapies for the treatment of cancers and other illnesses. Good Design Australia, an international design promotion organization, recently named the CFC a 2017 winner in product design for medical and scientific products, notes Mike Luehr, applications technology manager at Dukane.

Not all medical device manufacturers have implemented LPW, however, and there are many reasons for this. The main one, until recently, was the inability to weld two thermoplastic parts made from unfilled polymer. However, the emergence of laser systems capable of welding these assemblies have effectively eliminated this obstacle.

“Many medical device manufacturers are not excited about having carbon black in their products,” says Savitski. “From a purely marketing point, a dark medical device isn’t appealing

aesthetically. But, more importantly, companies don’t want to risk the carbon black coming in contact with the medicine that sits in or flows through the device.”

Lack of awareness or knowledge of LPW is another reason why some manufacturers don’t use it. Companies may also have determined that the technology isn’t cost-effective, based on their production volume relative to budget.

Equipment suppliers say the initial cost to get started with LPW is at least $150,000. To justify that amount of money, they recommend that the company produce a minimum of 100,000 to 250,000 parts per year. There are exceptions, of course.

The PowerWeld series of machines (2000, 4000, 6000 and 8000) from LPKF can be equipped with either a 1- or 2-micron laser for medical device applications. The higher the series number, the larger the scan area and parts that can be welded, notes Liddle.

“All of these units perform scanner welding, and feature a galvometer, which is a mirrored box that can move the laser beam in any rastered shape or path to complete the weld,” explains Liddle. “So long as the parts are flat and the weld area is exposed, the beam can be moved to weld around any part, or the beam made stationary and the part rotated under it.”

Later this month, Leister will unveil its Basic S system, which Geiger says easily integrates into any LPW platform for the medical industry. The system offers a modular design, state-of-the-art laser technology and continuous cooling of the laser to ensure precise and repeatable welding of plastic

components.

Optional software records and archives all welding process data and parameters to help medical device manufacturers meet their traceability requirements. Also unique is technology that enables the system to divide users into three categories (operator, expert and service) and give each group different capabilities.

Several years ago, RoweMed AG (based in Parchim, Germany) used Leister’s Novolas Workstation (through-transmission system) to weld a transparent lid on each side of the company’s RowePump midsection, which is dyed blue. The self-powered, pocket-sized infusion pump is made from a lightweight polycarbonate and used to administer medications, such as pain treatments and antibiotics. The modern Novolas WS-AT (Workstation Advanced Technology) is equipped with a 600-watt diode laser that produces a wavelength to match the needs of the application.

Quality Concerns

On the quality control side, several technologies and practices can ensure a good weld every time. Most of Blackhawk Technology’s focus is on infrared (IR)-based systems that perform three types of post-weld non-destructive analysis: bond integrity inspection, part location and material defect recognition.

According to Hamilton, the system is designed for just-welded opaque parts that are IR transmissive on the top and IR absorbent on the bottom. After such a part is bathed in IR radiation, the inspection system is activated. Its custom camera, lens and filtering have an illumination design that catches the IR radiation reflected off the internal part and allows the camera to see through the opaque part. Built-in proprietary software reliably performs all three types of analysis in milliseconds, making the system effective in manual or automated applications.

LPKF has recently introduced Calibrated Workspace software for use with its LPW systems. Liddle says the software helps manufacturers with several welding facilities worldwide ensure the same welding parameters and quality at each location. It does this by exactly matching the weld locations provided on a part CAD drawing with the actual physical space in the welder. The software also validates where the beam goes throughout the welding process.

“For accurate real-time feedback during LPW, especially regarding weld temperature, a pyrometer is essential,” claims Geiger. “This built-in instrument measures the infrared radiation to automatically evaluate weld seam quality. As long as the temperature curve stays within the specified band between the highest and the lowest limit, the welding system identifies the weld as successful. The pyrometer signal can also be used to detect material irregularities (burns, scratches, etc.) or contamination along the weld seam.”

LPW system installation is typically a two-step process, especially for medical device manufacturers. The FDA, in fact, requires each manufacturer to validate the processes used to manufacture a specific device. Step one is customer acceptance, which is when the customer signs a written contract saying the supplier’s equipment properly welds the customer’s parts at the supplier’s test facility.

Step two is multifaceted and occurs after the supplier has reassembled the purchased system at the customer’s facility. First, an equipment installation qualification (IQ) is done. Hoover says this involves setting up the equipment in accordance with supplier installation drawings and specifications, and verifying calibration.

Next is equipment operational qualification (OQ), which verifies that the laser welding system meets the manufacturer’s performance specifications. In the case of medical devices, the focus is on things like laser weld spot positioning.

Finally, there’s product performance qualification (PPQ). Testing at this point is done to simulate the operating environment of the finished product, and verify functionality and safety. PPQ tests include life cycling, temperature, vibration, humidity, impact and shipping. Should weld failures occur during PPQ, the basic product design for weldability must be revisited and the laser weld revalidated, according to Hoover.

Savitski says manufacturers need to be mindful of parts with damage or unsightly marks near the weld area, including those caused by ejector pins. They should also design parts accordingly. A proper weld design for laser welding is as critical as for any other welding process.

Is LPW Best for Your Application?

Four Questions to Consider

Innovative and much-talked-about assembly technology may be appealing, but that doesn’t mean it’s appropriate for every application. Medical device manufacturers need to thoroughly research if and when LPW is a great fit for one of their products. The following four questions can help the discernment process:

- What is the budget for this project? Hamilton acknowledges that LPW is more expensive upfront than ultrasonic welding or adhesive bonding, but it’s usually cheaper in the long run. In addition, LPW equipment always requires some customization, even if the machine is standard. Therefore, a company needs to be honest about how long it will take for ROI based on current and future planned production levels, notes Luehr.

- Has the plastic part been designed, or can it be, with laser welding in mind? Factors like basic shape and material are never insignificant when it comes to welding, especially laser welding. It may turn out, after much effort, that the final part design simply won’t allow for laser penetration of the weld joint, says Luehr, thereby eliminating LPW as a viable assembly process.

- What experience do your suppliers (equipment, material) have regarding laser welding? Hamilton says he can’t stress enough the need to get experts involved early. Failure to do so can result in design or material problems, and it’s the main reason LPW fails to be adopted by medical device manufacturers. Equally important, assemblers should always work with a company that provides reliable service before and after the machine has been delivered.

- How much room is available on the plant floor? If the answer is “not much,” then a lower-volume tabletop LPW system is the only option. But, if the answer is “plenty,” the manufacturer has the option of a high-volume inline or stand-alone system.