WORCESTER, MA—Worcester Polytechnic Institute (WPI) has received a three-year, $25 million award from the U.S. Army Combat Capabilities Development Command Army Research Laboratory (CCDC-ARL) to advance the cold spray 3D-printing technique that could be used to repair vehicles and other critical technology in the field. Having this capability avoids the sometimes extensive wait for new parts and increasing the readiness of military units.

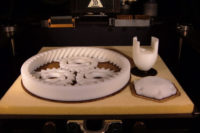

The cold spray technique can be used to repair metal parts or even make new parts from scratch by building up metal layer by layer in 3D printing. Cold spray uses a pressurized gas to accelerate metal powders to near supersonic speeds. The force of impact causes the powders to adhere to the metal upon impact. There is no need to first melt the powders. The process can be reduced to a portable handheld applicator, which makes it attractive for use in the field.

“The Army is interested in cold spray 3D printing as a repair technique,” says Danielle Cote, assistant professor of materials science and engineering and director of WPI’s Center for Materials Processing Data. “It’s cheaper to repair a part than to replace it, and you get the equipment back in service faster. The Army’s primary interest is unit readiness. If you’re on a mission and need to move quickly to a safer place, and a critical part on your vehicle breaks, you’re stuck unless you can repair it quickly. That’s where cold spray comes in.”

WPI’s primary focus in this research will be on developing, characterizing, and testing new alloys optimized for use in cold spray. Cote says the characteristics of the metal powders used in cold spray are critically important since the metal is not melted before being sprayed onto a part that needs repair, nor is it heat treated after application. “With most manufacturing methods, metal alloys are alerted by first being melted, and then often heat treated to strengthen or otherwise improve their properties. With cold spray, what you end up with in the repair is exactly what you start with, so the characteristics of the powders are quite important.”

WPI will develop and study powders using a variety of state-of-the-art equipment, including instruments acquired as part of the new ARL award. These include tools to study the chemical and structural properties of the powders at the scale of nanometers, such as a SEM/EDS (scanning electron microscope and energy dispersive spectroscopy) unit, a synchronous laser diffraction and dynamic image particle analyzer to determine powder morphologies, and nanoindenters to measure nano-scaled mechanical properties.

The WPI research team, which includes postdoctoral fellow Kyle Tsaknopoulos, will also work with several subcontractors, including the University of California Irvine, the University of Massachusetts Lowell, Penn State University, and Solvus Global. A spinoff of WPI including two recent WPI PhD recipients in materials science and engineering—Aaron Birt (2017) and Sean Kelly (2018)—Solvus Global will provide commercially available powders and modify them to meet the research team’s specifications so they can be tested in actual cold spray applications.

WPI Receives $25 Million Award to Bring Cold Spray 3D-Printing Techniques to the Battlefield