STUTTGART, Germany—Daimler AG has ramped up battery production at its Hedelfingen plant. The facility, which is assembling battery packs for use in the new Mercedes-Benz EQS electric sedan, will also support the upcoming EQE sedan.

In-house vertical integration plays a key role in the company’s EV initiative.

“Having integrated battery production seamlessly alongside existing transmission production, the Hedelfingen plant has been transformed into an important part of [our] global battery production network,” says Markus Schäfer, a member of the board of management at Daimler. “Quick ramp-up of global battery production capacities and targeted expansion of battery competencies through the entire value chain are key pillars of [our] electric initiative.”

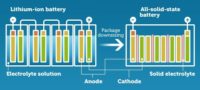

“As part of the transformation of our company and our products, we are significantly expanding our battery competencies across the entire value chain,” explains Schäfer. “Thereby, we continue to make efforts to help the next generation of batteries achieve a breakthrough even faster.”

According to Schäfer, the Hedelfingen plant features a wide range of Industry 4.0 technologies. “The highly complex lithium-ion battery system is produced on a 300-meter production line with more than 70 production stations [consisting of] a high number of automated as well as manual steps,” he points out. “A variety of components, including up to 12 cell modules and the EE-compartment for the intelligent integration of power electronics, make up the EQS battery system. The EE-compartment is assembled at our factory in Berlin.”

To deepen its competence as a center for battery technology, Schäfer says a new facility in Hedelfingen for low-volume production of future lithium-ion battery cells will also be in operation by 2023.