The automotive industry has been experiencing an unprecedented transition that will lead to a complete revision of the mobility concept. Totally new principles around the idea of driving—autonomous, connected, electric, shared—are proceeding decisively, albeit at different speeds. While fully autonomous driving is still considered a long-term goal, the spread of electric vehicles is a definite trend affecting all automakers and suppliers.

The electrification process is creating a radical revolution in a market that has traditionally been populated with well-known, long-established rules and players. In the past, the process of continuous innovation in power train technology, aimed at improving performance and reducing environmental impact, has focused on technologies related to the internal combustion engine (ICE). Today, the advent of the electric power train has reset this situation, essentially putting everyone back on the same starting line.

It is no coincidence that the best-selling brand of EVs today—Tesla—did not start with existing ICE technologies. Similarly, leading producers of lithium-ion batteries have seen new opportunities open up with access to the automotive market.

OEMs and Tier One suppliers that have traditionally focused on the automotive market have had to adopt their products and convert their production facilities to compete in the EV era.

This situation has somewhat favored suppliers that were already supplying components similar to those used in electric power trains. The need of automotive OEMs to quickly get to market with hybrid or full electric solutions initially tipped the scales toward the use of external suppliers for main components, such as batteries and motors.

However, this is a transitory condition that is not sustainable for automakers in the long term, as it excessively shifts the costs of the car to the “buy” side. In fact, all major car manufacturers are gearing up to become more vertically integrated.

While this complex scenario is rapidly evolving, engineers must find a way to deal with pre-existing technical and production realities. It is the norm to expect new teams of technology specialists within the R&D and prototyping departments to meet the new power train requirements. However, production environments are seeing personnel with great experience in the ICE world now being converted to EV projects.

EV startups are also facing production problems and quality standards that are typical in the automotive world. There are skill and experience gaps that will take years to fill.

ICE vs. EV Testing

The EV market presents a dynamic and rapidly evolving scenario, but it is still a sector that is taking its first steps when compared to the traditional automotive industry.

The scenario is made even more complex by the very nature of the key components involved in this transition. From a purely mechanical point of view, an electric power train has a much lower level of complexity than an ICE. On the other hand, to guarantee quality and reliability, other parameters become relevant, such as electrical and magnetic quantities.

In the case of batteries and fuel cells, compliance with extremely restrictive safety conditions plays a fundamental role. This can only be satisfied by means of controls that address the electrochemical behavior of the system.

With these premises, it is practically impossible to bring the topic of quality control back to the field of pure metrology. It is necessary to develop transversal skills to problems that no longer include only measurement, but also inspection and testing of different heterogeneous parameters that are often interconnected, to determine the functional behavior of the component.

The main characteristics of these components and the peculiarity of the processes with which they are produced require the use of different technology, even in cases where purely dimensional checks are required.

For instance, continuous flow processes are often used on extremely sensitive and delicate materials. Noncontact technologies are becoming increasingly widespread, both for measurement and for inspection and nondestructive testing. In many cases, the best solution to EV measurement challenges can only be achieved by combining different techniques.

The universally recognized quality standards for the production of ICE vehicles are the result of a progressive fine-tuning operation that was able to make use of more than a century of laboratory experiments, design and production experiences, combined with feedback from a vast fleet traveling in diverse environmental and use conditions.

This breadth of field evidence is not yet available for EVs, and laboratory simulations can only partially compensate. This is a condition that we must carefully consider, and whose effects we see every day in addressing the issues of quality and process control on electric power train components.

Testing Standards Variability

A striking example is represented by the tightness controls required on EV battery packs. All automakers define sealing standards (from IP67 up to IP6k9k) which ultimately refer to the need to ensure the impermeability of the pack from water or other forms of infiltration that could compromise its functionality.

However, the IP specification actually refers to a functional type of performance that may depend on various factors, including the methods of design, execution and assembly. These variables are unlikely to translate into univocal test specifications. As proof of this, the leak test specifications defined by different producers can differ by various orders of magnitude, although the required function is always the same: to guarantee the perfect sealing of the pack.

In cases like these, engineers must be able to adapt to different specifications, with different parameters that can range from tests in air (pressure drop or mass flow) to more sensitive tests with tracer gas, by sniffing technologies or in accumulation or vacuum chambers.

Engineers must also take into account the fact that testing specifications could change and become more stringent when particular types of failure are found in the field. As a result, it’s important to provide a sufficient degree of flexibility and be able to adapt to regulatory standards that may be still evolving.

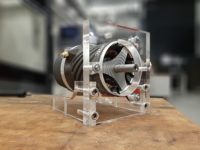

Another critical challenge with EVs concerns the insulation tests on electric motor components (typically stators or wound rotors). The tests imposed by the regulations (such as surge or hi-pot) can, in fact, only identify the existing insulation defects. They are not able to highlight latent defects, which can trigger perforation of the insulation and generate defects that will appear only with the use of the motor.

However, the use of partial discharge test techniques that we usually suggest to identify latent defects is not yet imposed by automotive regulations. In the future, more OEMs and suppliers will be forced to adopt them to improve the reliability of their products.

Increasing Speed and Complexity

Intense competition and the drive for continuous innovation also involve other particularly significant aspects for companies that want to play a leading role in quality and process control in the world of electromobility.

The typical timing for the launch of a new car model is progressively shortening. This entails the need to be involved in the definition of control and measurement in a very early stage of the project. EVs present an even greater need to operate in concurrent engineering mode than what was already required for ICE projects.

The proliferation of new models in the face of still low sales volumes, and the need to collect experience and data, also demands measurement, inspection and testing technology that can guarantee maximum flexibility, even at the expense of the cycle time.

But, growth in sales volumes with the spread of EVs on the market will reduce production costs and improve the efficiency of assembly lines.

This will lead to a reduction in cycle times, even in measurement and testing operations. Investments in process control along the entire line will be intensified to reduce scrap percentage on the finished product.

In some areas of EV power train production, overall equipment effectiveness might not compare yet with the traditional standards, but this must change. There will be more opportunity for companies that have quality and process control experience within the automotive sector to transfer this knowledge to address problems associated with EV power train components.

It will be essential to know how to adapt to the rapid innovations that will characterize the EV sector in the coming years. Manufacturers that succeed will apply state-of-the-art technology dedicated not only to measurement and inspection in the strict sense, but more generally to control of new processes and execution of functional tests.