Stroke is a leading cause of death and disability in the United States. Each year, about 795,000 people here suffer strokes, of which 17 percent are fatal.

Medical device manufacturer Imperative Care of Campbell, CA, is trying to do something about that. The company was co-founded in 2016 by Nick Hopkins, MD, a pioneer in neuroendovascular surgery, and Fred Khosravi, a serial entrepreneur and managing partner at medical incubator Incept. Their goal was to create new technologies to improve the quality of life for stroke patients beyond the acute-care setting.

Medical device manufacturer Imperative Care is developing new technologies to treat strokes. Photo courtesy Propel Software Solutions Inc.

As a medical device manufacturer, deploying a dedicated, scalable quality management system (QMS) was essential to maintaining compliance across the product life cycle as the company continued to scale both its workforce and product portfolio. Supporting a remote workforce made the company’s paper-based change approval process all the more challenging.

“Because of how quickly we were growing, we knew we needed a system that was configurable, scalable and could provide guidance going forward,” says Donielle Baudin, director of quality at Imperative Care at the time and now director of quality assurance at Noah Medical in San Carlos, CA. “We needed a way to improve compliance within our processes across the board.”

Paper-based quality management makes it challenging to integrate quality with the design and development phase. Without having clear insight into quality issues during the design phase, engineers risk the possibility of designing products with components that may have been associated with a quality incident or complaint.

“We realized that we needed to be able to track product and component problems all the way back to the PLM [product life cycle management] structure. We needed to be able to see if an item has been related to any quality incidents before it made its way into the next part,” says Baudin.

With its homegrown system, engineers had to actively seek the information in a spreadsheet instead of having it readily available during the design phase, leading to longer development times and potential missed opportunities to improve quality. Imperative Care quickly discovered its previous method for tracking corrective and preventive actions and nonconforming material reports was an inefficient way to get their products to market.

“We really needed that closed-loop between PLM and QMS,” Baudin adds.

The paper-based process also made it more challenging and time-consuming to collaborate across teams and projects. “We have employees who are offsite and getting signatures from them was very difficult,” says Baudin. “For changes or approvals, everyone had to pass around paper or share spreadsheets,” she adds. “It was very inefficient.”

To increase efficiency, collaborate effectively, manage quality and get its products to market faster, Imperative Care needed cloud-native software that combined PLM and QMS in one platform that gave its team remote access from anywhere in the world.

The Software

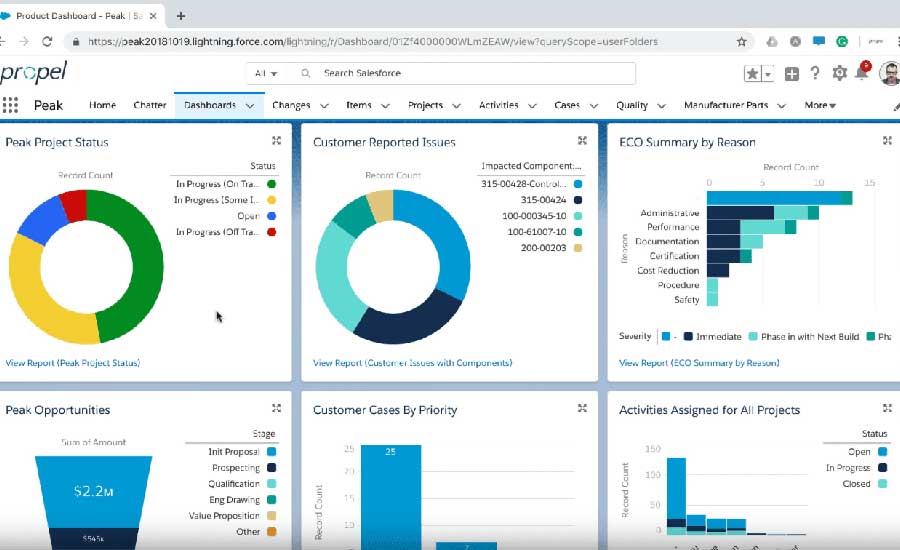

Propel Software Solutions Inc. in Santa Clara, CA, provides Imperative Care with closed-loop PLM and QMS software from design to final product in one cloud-native platform used by the entire organization. Propel is the hub for all product data and quality information, complete with dashboards, reporting, approvals, workflows, change orders, contextual collaboration and training records.

“By having PLM and QMS together in one system, we now have immediate visual access and a hyperlink into what problems might exist,” says Baudin.

Engineers have full visibility into any quality issues in real time. They also have complete PLM functionality and the ability to tie the bill of materials (BOM) to their quality records for future product iterations.

Propel software serves as a hub for all product data and quality information, complete with dashboards, reporting, approvals, workflows, change orders, contextual collaboration and training records. Photo courtesy Propel Software Solutions Inc.

“With Propel, we can easily track quality issues from finished goods and ensure they are addressed during the design phase of future versions,” says Baudin. “We are able to quickly analyze the data in front of us and examine if it’s a single incident, multi-incident or specific to a particular size or component,” she explains. “Now, I can monitor quality much more closely and more rapidly instead of spending time looking at a spreadsheet for those answers.”

Propel delivers a cloud-native platform that enables complete remote access of the product life cycle from any device or region. All communication, product updates, changes and approvals are now completed within the platform without the need for physical paperwork. Imperative Care no longer has to distribute paper documents or a spreadsheet file as part of its product development process.

“It’s great because it’s all done electronically now. We no longer have to make copies or spend our time filing,” says Baudin. “The fact that we can remotely access any document or any piece of information from our quality system worldwide is tremendous.”

Results

Propel’s comprehensive dashboards and reports have enabled Imperative Care to spend less time on administrative work and more time creating life-changing products for their customers.

“At a moment’s notice, we can see the pulse of where our quality system lies. My management review process has gone from five days of data crunching and analyzing graphs and spreadsheets to a 5-minute report and I’m done,” says Baudin.

The modern and user-friendly interface has also enabled Imperative Care to quickly onboard and ramp its employees.

“We were able to [train more than] 100 people in the first week,” says Baudin. “The user interface is modern and consistent, making it a lot easier and faster for our employees to learn and use.”

The easy-to-use interface helps Imperative Care ensure simple onboarding and training, and preserve knowledge continuity going forward as its workforce evolves. The ease-of-use has been especially helpful in training Imperative Care employees on critical, time-sensitive updates and documentation.

“Before Propel, we used an Excel spreadsheet for our manufacturing operators, which wasn’t entirely accurate in recording training assignments because it relied on the individual to fill it out,” says Baudin. “But with Propel, the first thing an employee sees in the platform are any open training assignments they need to complete. The visibility into who has and hasn’t completed training has been extremely helpful for us. We no longer need to log into another platform to manage and track training compliance. It’s all there in Propel.”

By decreasing the time spent on change approvals, Imperative Care has been able to get its products to market faster. “We’ve drastically reduced cycle times for change reviews. In our old system, reviews were done in series, so person A looked at it then person B and then person C. With Propel, everyone can view them in parallel. Release activity has gone from a 20 to 30-minute process per document to three mouse clicks and we’re done, and the product is released,” says Baudin.

Because Propel is a cloud-native platform, Imperative Care is able to access its product information from anywhere in the world. “With Propel we’re able to work remotely from anywhere. Plus, as we continue to grow as a business, we are able to rapidly onboard employees and bring them into the same processes quickly,” says Baudin.

Like many organizations, Imperative Care recently experienced the need for remote access during the COVID-19 shelter-in-place restrictions in Santa Clara County. “We would be in a world of hurt if we didn’t have Propel. The platform has enabled us to stay in business during a critical time, since we make products for emergency care patients,” says Baudin.

Propel’s closed-loop platform helps Imperative Care get its products to market faster, maximize customer satisfaction and safety, and maintain compliance across any regulatory environment. “Because everything is done in one platform, we don’t have to spend time hunting for information,” says Baudin. “Now, we can actually focus on day-to-day business needs and future strategy.”

MORE FROM ASSEMBLY ONLINE

For more information on manufacturing software, read these articles:

Automotive Supplier Increases Efficiency With PLM Platform

Bombardier Improves Assembly Flexibility Thanks to Manufacturing Operations Management Software

Five Digital Transformation Failures and How to Avoid Them