Flexibility, performance and cost, (both capital and operating) have always been key factors in today’s expanding manufacturing marketplace. For decades hydraulics and mechanical presses were the only options for high-speed, high-force assembly and forming applications. More recently hydra-pneumatics and servo based systems have emerged as viable low-cost alternatives. So which technology is best suited for a specific application? We highly recommend contacting Aries Engineering application-specific information but the following topics can serve as a guideline towards the correct usage.

Aries Engineering is the only manufacturer Headquartered in North America offering both hydra-pneumatic and servo driven solutions.

Servo-Based Technology - HyperCyl-EMA

Capability: Provides exceptional control over force, speed and distance characteristics. Requires the use of a full PLC/PC based electrical panel and 230V/460V. Best used for push-to-distance or push-to-force applications, push/pull applications and where Extreme repeatability is essential. Signature analysis, data logging, part history, trending and root cause analysis options are also available for added functionality and tracking.

Reliability: Servo technologies are inherently capable and sizing them appropriately is crucial. Expected lifetime is from 1 Year to 5 Years, configured for any particular application. Long-Term Reliability coincides with maintenance schedules.

Speed: Up to 16.00 in/sec with an extremely high rate of repeatability. Requires a deceleration setting before Contact and Home to maximize tooling and screw life.

Forces: 1-10 Ton in Ball Screw configurations (BS1 & BS2) with a medium dynamic load rating; 1-25 Tons in the Roller Screw configuration with a high dynamic load rating.

Maintenance: 3-6 month lube schedule & periodic belt tension check dependent on usage and environment.

Cost: Can be higher initial cost than comparable Hydraulics. Energy efficiency and ROI achieved with low down-time, low noise pollution, ZERO environmental pollution, comparable energy usage to hydraulics without the mess.

Hydra-Pneumatic Cylinders - HyperCyl

Capability: Utilizing 2 pneumatic valves for operation and a FRL greatly reduces start up time. Cylinders are available in 5 design configurations and 11 standard sizes. Best used for; crimping, dimpling, peening, swaging, inserting, clinching, pressing, staking, piercing, punching, marking, bending and forming. When coupled with the IntelliCyl option, (load cell and LVLT) force distance monitoring is available.

Reliability: (MTBS) Mean time between service interval of approximately 4-5 million cycles because down time is not an option. LIFETIME warranty on all HPI – HPS – HZ – HZS – HPT cylinders, 1-Ton through 200-Ton.

Speed: Fast Approach speeds similar to that of a pneumatic cylinder (6 in/sec – 10 in/sec) and High Pressure speeds similar to that of hydraulic cylinders (1.0 in/sec – 2.0 in/sec).

Forces: 1-200 tons of output force using 30-100 PSI shop air.

Maintenance: 20 million cycles before seals require replacement. Field serviceable by maintenance techs and 24 hour Hypercyl assistance is available. Periodic maintenance depends on application and environment.

Cost: More expensive than Pneumatic cylinders but offers the same Clean, Quiet & Self-Contained operation. Less expensive than hydraulic and mechanical systems for both short & long-term investments.

Additional Products

HyperView Press - SigPOD

IntelliCyl - load cell & linear transducer

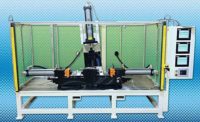

HyperPress-C Frame, H Frame, CGB Frame

Equalizing/ Non-Equalizing Units Pneumatic

Mechanical Rod Locks

Industries Served:

HyperCyl

Manufacturing Industries Served —

Automotive, DoD, lawn & garden, appliance, HVAC, food & beverage packaging, destructive testing, ATV/Off-road

HyperCyl-EMA Industries Served — medical device manufacturing, aerospace, automotive, food product manufacturing, clean room environments, lab testing

Contact an Aries Engineering representative today to size the appropriate technology for all of your assembly and forming needs.

Phone: (734) 529-8855

Fax: (734) 529-8844