Having multiple options to solve a problem is a great thing for any manufacturer. Having too many options, however, can prove problematic when it prevents a company from deciding on a specific plan of action in a timely manner.

A good example of this is weighing the positives and negative of too many integrators for a specific assembly project. To avoid this problem, manufacturers prefer sticking with one such company as much as possible for as long as possible.

Fiat Chrysler Automobiles (FCA) and D&D Automation Inc. have established this type of relationship to most effectively complete conveyor improvements at the manufacturer’s plant in Windsor, Ontario, Canada. Founded in 1992, D&D Automation is a Stratford, Ontario, process control systems integrator that specializes in turnkey systems. Key markets for the company are automotive, metals, mining, and food and beverage. Process specialties include conveyance, automotive welding and paint systems.

In fall 2014, D&D upgraded the electrical controls of conveyors on a robotic sealer production line within the paint shop. The engineers installed new Allan-Bradley GuardLogix safety relays on the conveyors’ older A-B PLC5 platforms, and integrated the conveyors with many new pieces of equipment.

They also faced several challenges. One was being flexible enough to incorporate several design changes midway through the project, including splitting the friction drive control into two PLCs. Another involved relocating the conveyor control into process PLCs and removing other controllers.

D&D engineers needed to integrate new code into existing PLCs, which required significant coordination, and overcome several mechanical delays that occurred late in the project. They also made sure that the conveyors meet all relevant safety standards, and use basic programming to ensure simple maintenance by the dedicated staff.

The project lasted nine months for D&D. Its engineers performed electrical design work from November 2014 to April 2015, and worked onsite from late February, when production was shutdown, until August 2015. The shutdown occurred for a massive retooling to build the next generation minivan and the Chrysler Pacifica. Production restarted on time, in May 2015.

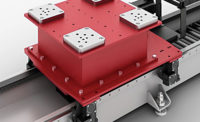

About two years later, D&D upgraded the process controls on 13 inverted power-and free conveyors and seven CPUs in the body shop. The integrator also provided designs for two conveyors and several CPUs as part of a new plant layout that included a just-installed Ethernet I/O network. Completed during a short-term shutdown, the project is classified as one of the most significant in the history of the Canadian automotive manufacturing industry.

All of the control systems were upgraded to meet Chrysler’s latest standards and include A-B GuardLogix safety relays. Remote I/O and Data Highway+ communication networks were also updated, and required the relocation of newer HMIs, and the replacement of older HMIs with Panel View 900, 1000 and 1400e models. On the new conveyors, D&D installed AB ControlLogix 5000 controllers and Panel View Plus 1500 HMIs to give operators greater control.

Despite the project’s complexity, the plant restarted on schedule to limit downtime. D&D’s timely project completion, combined with many benefits that FCA has experienced from the upgrades over the past two years, accounts for its willingness to work with D&D again in the future.

For more information on upgrading the control systems of conveyors and other automation equipment, call 519-273-7282 or visit www.ddauto.com.