Lubricity is more than a just a cool word. It is the slipperiness needed on a fastener to achieve controlled torque during assembly. A wide variety of lubricants are specifically designed for this purpose, ranging from beeswax polish and anti-seize grease, to silicone spray.

Often overlooked is the lubricity offered by threadlockers, which are well-known for keeping fasteners tight and immune to vibration. These anaerobic adhesives fill the grooves of threaded fasteners, then harden to a tough solid when exposed to metal ions in the absence of air.

“Threadlockers ensure that whatever you put together, stays together,” says Mark Thurber, CEO of Tectorius. “They prevent nuts and bolts from loosening and coming off due to vibration and motion. But, equally important, the adhesives can go as far as imparting the right amount of slipperiness, or lubricity, to the bolt in the created joint. This optimizes the entire assembly.”

Tectorius has specialized in pre-applied threadlockers since 2004. The company also offers bottled and spray threadlockers. Its main customers are manufacturers in the automotive, aerospace, electronics, recreational equipment and white goods industries.

A few years ago, a leading manufacturer of automotive components was experiencing a problem with its window regulators. Customers were hearing the amplified rattling of four window regulators within their vehicle doors.

The parts in the regulators were not fitting together properly, leaving room for vibration (and therefore, noise) in the pulley assembly. Because the parts are made of hard plastic, a traditional threadlocker could not be used on the gear, according to Thurber.

“We had them apply a few drops of our Vibra-Stop threadlocker to the gear spline,” explains Thurber. “Unlike most threadlockers, Vibra-Stop is effective on plastic surfaces and does not cause any long-term damage. In this case, it acted as filler between parts, thereby damping vibration and eliminating noise.”

First developed in 1953, threadlockers have an established track record of preventing threaded-fastener failure. Add in the adhesives’ flexibility factors—that it can be pre-applied or applied on the assembly line, and provide temporary or permanent fastening—and it is easy to see why their use by manufacturers is secure for many years to come.

The Good, Bad and Colorful

When it comes to bolted joints, nothing is more important to a manufacturer than preventing fastener failure. Several things can cause this failure, including overloading, fatigue, shearing, galling, tension relaxation and self-loosening. Threadlockers help prevent the latter three problems.

“Threadlockers do much more than just protect the bolted joint from vibration,” notes Alex Clark, an application development specialist at Permabond Engineering Adhesives. “They lock and seal fasteners against impact and corrosion, and serve to stop fluid, gasses and moisture from passing through the joint.”

Another important benefit, according to Clark, is threadlockers enable engineers to design bolted joints using either less hardware or smaller fasteners. This results in cost savings and allows for product miniaturization.

“Preventing galling and corrosion are important benefits of threadlockers,” says Scott Simmons, a business development representative for auto powertrains at Henkel Corp. “Eliminating these problems makes it easier for the bolt or screw to be removed and then reused. Threadlockers can also be used on any size threaded fastener, from tiny screws in electronics to large bolts in agricultural equipment.”

Thurber does point out a couple of limitations regarding threadlockers. The first is that one type does not fit all situations. The specifics of each fastener must be carefully considered to find the right threadlocker.

“Knowing the fastener size and type is a good place to start,” says Thurber. “Also find out if the fastener and nut are plated, and what material they are going into or capturing. For example, a steel bolt going into an aluminum housing requires a different threadlocker than a steel bolt going into a plastic housing. Temperature and environment are other key considerations. Each threadlocker may be only serviceable within its certain temperature range or exposure limits.”

Suppliers provide several types of threadlockers, categorized by material type, strength grade, viscosity and application method. Threadlockers come in liquid, spray and gel formulations. Excess threadlocker that overflows the threads during application remains uncured and can be wiped away.

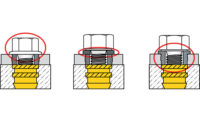

During curing, the threadlocker forms polymer chains and completely fills the microscopic gaps between interfacing threads. This action positively locks and seals assemblies, and prevents lateral movement. Threadlockers provide 100 percent contact between metal parts, compared to a typical nut and bolt assembly that may have as little as 15 percent metal-to-metal contact.

Low-strength formulations allow for easy fastener removal. Common hand tools are needed for medium-strength grades. High-strength formulations are intended for permanent fastener installation, but may be able to be removed with special tools, or standard hand tools and heat (400 to 450 F via a propane torch or induction heater).

Strength grade is also directly related to fastener size. Low-strength threadlockers are recommended on screws up to 0.25 inch in diameter that will need ongoing adjustment. Medium-strength is for fasteners up to 0.75 inch in diameter used as mounting bolts or in machine tools, presses and pumps. High-strength threadlockers are designed for fasteners up to 1 inch in diameter in heavy equipment and various mounts.

Strength level is visibly indicated by a specific color. Several years ago, USA military specification MIL-S-46163 dictated this color scheme, which includes purple for low strength (50 to 100 psi), blue for medium strength (115 to 200), red for high strength (200 to 350) and green for wicking or penetrating grade (90 or so). It is important to note that most, but not all, threadlockers are coded according to this scheme, and that the MIL spec is superseded by ASTM D5363 for new designs.

“We can customize the threadlocker color and physical properties for our customers for various reasons,” notes Thurber. “A company may want the typical red threadlocker to be green because it matches their company logo color. Or maybe their workers use two different-length fasteners in an assembly, so they want one to be pink and the other to be green to help the workers distinguish which one to install where.”

Low-, medium- and high-strength threadlockers can have a low, medium or high viscosity. Clark says that Permabond threadlockers have a viscosity range from 12 to 23,000 centipoise (cps), noting that water has a cps of 1. A threadlocker with a higher cps flows less, but more easily fills metal-to-metal gaps and is recommended for larger fasteners.

Under shear stress, the adhesive exhibits a time-dependent decrease in viscosity. This allows it to flow well over time, yet still resist short-duration vibration or shock. Low-viscosity formulations easily wick into pre-assembled fasteners up to 0.5 inch in diameter.

On the assembly line, threadlockers can be applied manually or with automated dispensing equipment. Pre-application ensures that the adhesive will actually be on the fastener, in the correct amount and in the correct location. The process also eliminates liquid mess, sloppy run-off and the possibility of running out of adhesive during production.

Mature Market

“The level of threadlocker use continues to grow as manufacturing overall grows,” says Thurber. “What’s different in recent years is that specialized products and threadlockers are becoming a more common request.”

In the past, for example, manufacturers would consistently install standard steel fasteners into steel parts to form a bolted joint and secure it with almost any low-strength threadlocker. Today, in contrast, Thurber says it’s commonplace for a specialty metal fastener to be installed into an aluminum (or other non-steel metal) part and require a custom threadlocker to ensure a high-performance joint.

Henkel’s extensive threadlocker offerings include Loctite 243, a general-purpose, medium-strength blue threadlocker. Dan Shaw, a category manager for machine adhesives at Henkel, says the primerless threadlocker tolerates minor surface contaminations from various oils, such as cutting, lubrication, anti-corrosion and protection fluids. It performs well on 0.25- to 0.75-inch-wide fasteners in high-vibration and high-temperature environments (up to 180 C). Treated fasteners can be removed with hand tools.

“Billions of fasteners are installed in general industrial applications every year, but a vast majority of them do not have a threadlocker,” says Shaw. “There are many reasons, including lack of awareness or knowledge about threadlockers by manufacturers, their refusal to change traditional assembly habits and a misperception of higher cost.”

Permabond offers 10 threadlockers, including removable and permanent formulations. MM115 is a general-purpose, removable threadlocker that offers fast curing and medium strength for locking screws, nuts and bolts in assemblies and machinery. Available in 10-milliliter to 1-liter bottles, the adhesive fully cures at room temperature and is typically used on zinc, cadmium, steel and other plated fasteners.

“Today’s threadlockers have evolved in cure speed and their ability to cure on passive surfaces without the need for an accelerator,” concludes Clark. “They are also better at tolerating surface contamination and resisting higher temperatures. These improvements have resulted from customers having more demanding expectations and suppliers meeting them.”