The biggest challenge in automatic screwdriving isn’t speed or torque accuracy: It’s getting the fastener to the tool reliably and oriented correctly. Fortunately, assemblers have several options for feeding screws to fully or semiautomatic drivers, including screw presenters, bowl feeders and step feeders.

The basic technology behind screwfeeding hasn’t changed dramatically in decades. However, in today’s post-Covid era, screwfeeding is more important than ever.

“We’re seeing a continuation of trends that were accelerated by the pandemic, such as eliminating the need for operator manipulation,” says Jarrod Neff, marketing manager at Visumatic Industrial Products Inc. “Two years ago, a lot of manufacturers turned to automation to create social distancing on their assembly lines.

“That forced engineers to take a serious look at screwfeeding,” explains Neff. “Recent labor shortages have also increased demand.”

“Automation is ideal for assembly tasks that are dirty, dull and dangerous,” adds Chris Emanuele, automation technical sales engineer at ASG, Division of Jergens Inc. “Screwfeeding is typically used to alleviate the dull component. It enables manufacturers to use humans for tasks that add value, instead of standing around loading fasteners.

“In addition, we now see more demand for high-mix, low-volume production applications,” Neff points out. “We’re getting requests for flexible screwfeeders that can accommodate three or four similar types of fasteners so that manufacturers can justify their investment in automation.”

Improving Throughput

Improving throughput requires automatic screw feeding. Feeders present fasteners quickly and properly oriented to the screwdriving tool.

There are several different ways to get screws to the driver. A simple, inexpensive solution is the shake-tray, where screws flow over a perforated metal tray that tilts back and forth.

Another option is to use a step feeder. “However, they traditionally operate with a slower output rate,” says Neff. “Step feeders are usually used to feed larger and heavier fasteners, such as an M8 screw or larger.”

Benchtop screw presenters are popular for many screwfeeding applications. A vibratory track orients screws and brings them to the end of a track where an operator can pick them up with a magnetic bit and then drive them.

“We’re seeing a little more demand for screw presenters,” says Neff. “It may have something to do with increased reshoring activity. Many manufacturers need to get more process control, instead of a productivity or throughput increase. They want to control each fastener and monitor assembly to help bolster quality.

“Statistical process control is becoming an important part of screwfeeding,” claims Neff. “Engineers want more data to lock down their process to ensure part quality.”

Screw presenters are a popular option for screwdriving applications that deploy collaborative robots, such as Visumatic’s VCM-3X.2 module developed for use with UR cobots. It includes an automatic screwfeeder, drive system, skeleton robot program and an end-effector for mounting directly to the wrist of a cobot.

According to Neff, the lightweight tooling mitigates the inertia effect on the robot’s sensors and allows the machine to move at maximum speed without sacrificing collaborative safeguards. The tooling also has a close center of mass, which minimizes the cantilever effect. The compact size of the tooling enables the robot to clear obstacles with less motion.

The screwdriver incorporates Visumatic’s bit-advance assembly with dual-powered motion for precise, controlled fastener installation. Position sensors on the slide confirm advancement and retraction of the bit, reporting to the robot controller that it is OK to move when the bit reaches the home position.

This ensures a repeatable joining operation. Other sensors report that a screw has been fed, that a fastening cycle has started and that torque is good or bad.

Blow feeding is another option that manufacturing engineers can consider using. An operator dumps screws into a hopper or vibratory bowl. The tooling orients each screw, brings it out to the end of a track, separates it and drops it into a feed tube. A blast of air shoots the screw to the end of the driver.

Autofeed screwdriving systems with DC drivers offer much greater control over the assembly operation. Fastener speed, torque, angle of rotation and tightening direction can be controlled and varied throughout the screwdriving process.

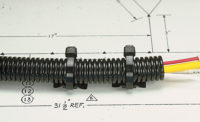

Autofeed technology involves orienting and delivering a fastener with compressed air via a feed tube connected to the screwdriver assembly. Components attached to the front of the screwdriver receive the fastener and maintain alignment with the screwdriver bit until the fastener is driven. Autofeed screwdrivers range from simple handheld systems to full-blown, turnkey robotic systems.

The fastest and most complex solution is to use a robot, along with a vibratory bowl feeding system tied into a multispindle screwdriver.

“Vibratory bowl feeders are still popular, because you can accommodate a wide range of fasteners,” says Emanuele. “They are ideal for applications that require high production rates and they come in many different sizes.

“However, bowl feeders can be noisy,” warns Emanuele. “They’re not too flexible and are typically set up for a particular type or family of screws.”

“The push to automate continues today, as many manufacturers seek to be leaner and more efficient,” adds Kevin Buckner, director of engineering at Design Tool Inc. "We’ve seen an increase in the use of multi-spindle screwdrivers to reduce cycle times. It’s also becoming more common to see a single bowl feeding six or more spindles.

“Automating the entire screwdriving process using fixtured equipment designed to drive all screws in an assembly can greatly increase throughput by reducing the number of operators required,” says Buckner. “This also frees the operator to perform other tasks while the screws are being driven.”

Both handheld and custom-fixtured machines are available. “In handheld applications, autofeed screwdriving equipment addresses these challenges by delivering the screws to the driver more quickly and eliminating the need for operators to handle the fasteners,” explains Buckner. “In fixtured applications, multiple drivers can be utilized to reduce cycle time or assemble multiple components simultaneously to achieve higher rates.

“Typically, screw presenters are used when the fastener dimensions prevent the screw from being blow-fed, or when the application does not allow [the use of] autofeed driver components,” says Buckner.

Screw presenters place a fastener at a pickup point so that the operator can insert a magnetic bit and engage the screw. The operator does not have to handle fasteners, which reduces waste from lost fasteners and improves quality by eliminating the chance of a dropped fastener entering the assembly.

As soon as the screw is removed from the pickup point, the presenter advances another screw, so the next screw is available as the screw is being driven, which reduces cycle time.

Some types of screws can be more challenging to feed than others.

“Slotted heads are typically the most difficult type of screw to feed, because you get a lot of bit skip when it tries to engage,” notes Emanuele. “Any type of screw with an encapsulated washer, such as fasteners used to assemble printed circuit boards and other electronics applications, can also present problems.”

As a general rule of thumb, the length-to-diameter ratio will determine how well a fastener feeds. That’s why small screws can be especially finicky.

“We [typically specify] vibratory bowls, as we can fill and grind all gaps [without] giving the parts any place to hang up on or stick to,” notes Greg Pflum, president of Performance Feeders Inc. “Vibratory bowls also give us more options for tooling to correctly orient the parts.

“The transfer point of the bowl to the gravity track or vibratory inline can be a problem area, due to the small screw size, including length and diameter,” explains Pflum. “Dirt holes also need to have attention paid to them to prevent good parts from getting stuck in them.

“We typically look at using a scarfed or tongue in groove transfer point so that you do not have a straight gap between the two transfer points,” adds Pflum. “Another option is to have the bowl discharge higher than the track running surface and overlap them, so you drop the parts into the track, eliminating the gap problem. For dirt holes, we look at small slots or open areas where we hang the parts to [avoid] holes for the screws to get caught in.”

One of the biggest challenges when feeding small screws is the overall length-to-head diameter ratio. “The closer that ratio is to 1-to-1, the more difficult it becomes to maintain the correct orientation of the screw in the feed escapement mechanism,” claims Vic Glenn, president of Design Tool Inc.

“With smaller screws, the tolerances of the feed components must be held more closely (tighter) to ensure that the mechanism will function correctly,” says Glenn. “Some small screws are difficult to orientate in the bowl before entering the feed mechanism because of the weight and size of the head.

“[We are] addressing the challenge of feeding smaller screws with custom designs of our feed systems, including slide systems that control the screw until it is released into the feed tube,” Glenn points out. “Our patented feed systems are very adaptable for smaller screw applications.”

Design Tool typically uses vibratory feeder bowl systems for small screws. However, the scale of the feed orientation and escapement components are smaller with tiny screws.

“The primary challenges in driving small screws with an auto feed system are maintaining the correct screw orientation within the screwdriver components and clearance around the screw head for the driver components to access locations in the customer’s assembly parts,” explains Glenn.