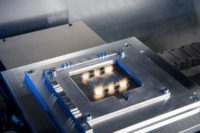

STUTTGART, Germany—Assemblers at Bosch’s Feuerbach factory have begun producing fuel cell modules for Nikola Corp.’s much-anticipated Class 8 truck, which will finally become available later year. Other local Bosch facilities are supplying components, such as fuel cell stacks, electric air compressors and recirculation blowers.

After several years of delays and setbacks, Nikola’s Tre FCEV truck will be assembled at a state-of-the-art facility in Coolidge, AZ. The heavy-duty vehicle is expected to have a range of up to 500 miles and an estimated fueling time of approximately 20 minutes.

“A hydrogen engine can do everything a diesel engine does, but on top of that, it is carbon neutral,” says Markus Heyn, chairman of Bosch Mobility. “It also allows a fast and cost-effective entry into hydrogen-based mobility. One major advantage is that more than 90 percent of the development and manufacturing technologies needed for it already exist.”

By 2030, Bosch plans to generate sales of roughly $5.3 billion with hydrogen technology. In addition to the German plant, the company is currently producing fuel cell modules at a facility in Chongqing, China.

Heyn claims that more than 3,000 Bosch employees are working on projects related to hydrogen technology. Earleri this year, the company started constructing prototypes for electrolysis using proton exchange membranes, which is the reverse of the energy conversion method used in mobile fuel cells. Starting in the fall, the company intends to make 1.25-megawatt prototypes available for pilot applications and is on track to start volume production in 2025.

Bosch is exploring several options for the future use of hydrogen, such as stationary solid-oxide fuel cells that can be used for the distributed supply of power and heat.

In addition to fuel cell power trains, Bosch engineers are working on hydrogen engines, developing systems for both port and direct injection of hydrogen. The H2 engine for heavy-duty vehicle applications will be launched in 2024.